Square well bottom drainage design method

A square well and well wall technology, which is applied in the fields of oil and gas drilling and well completion, can solve the problems of affecting the use and maintenance of wellhead devices, long construction period of dewatering and drainage, and groundwater entering square wells, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereby.

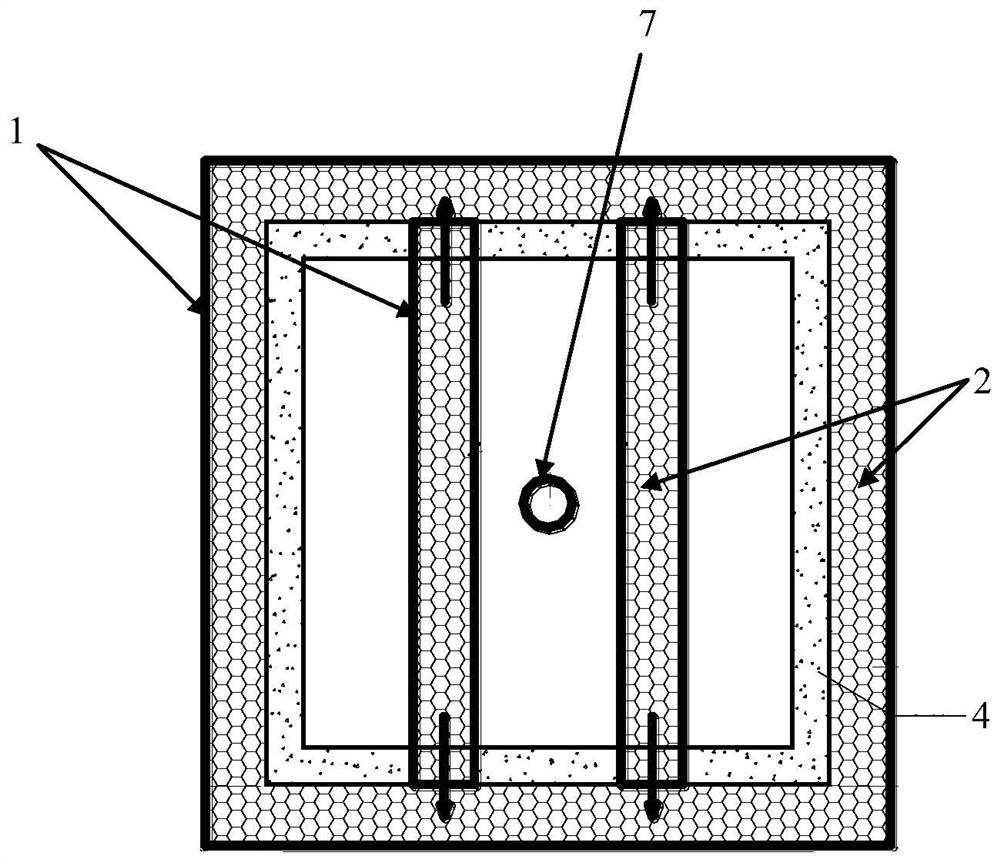

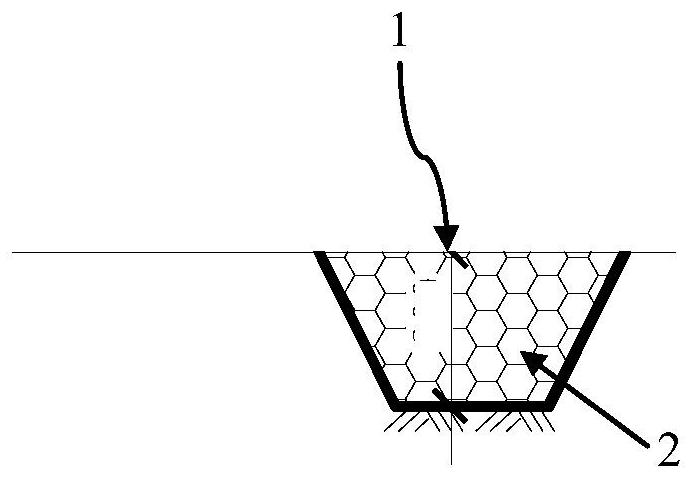

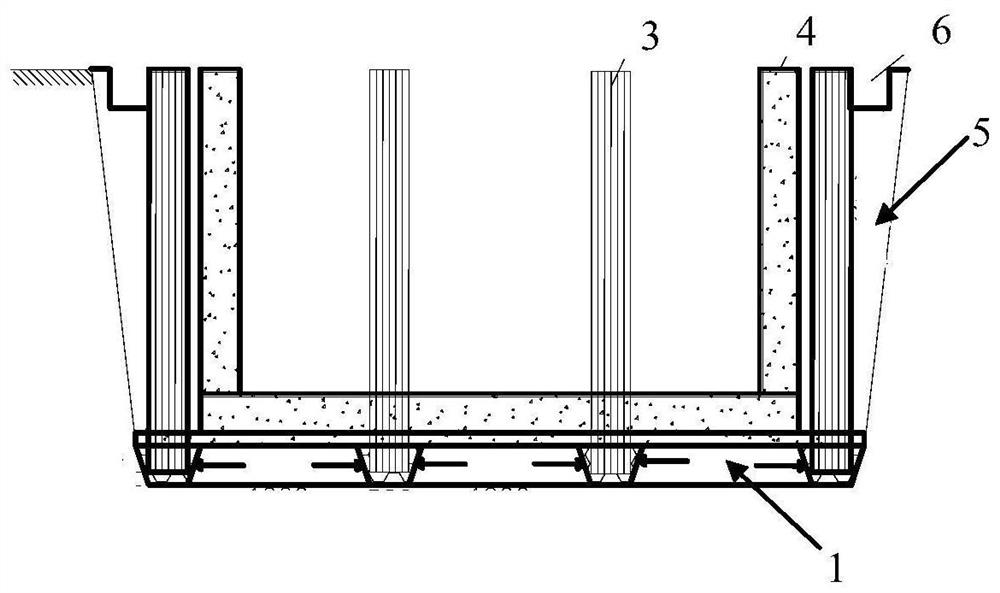

[0038] figure 1 Schematically shows the arrangement form of the water guiding blind ditch 1 of the embodiment of the present invention. figure 2 Schematically shows the cross-section of the water guiding blind ditch 1 of the embodiment of the present invention. image 3 Schematically shows the drainage design of the wall of the square well in the embodiment of the present invention. Figure 4 The top drainage design of the square well according to the embodiment of the present invention is schematically shown. Figure 5 Schematically shows the flow of the method for draining the bottom of the square well according to the embodiment of the present invention.

[0039] Such as figure 1 and Figure 3 to Figure 5 As shown, the method for draining the bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com