Clay core wall dam structure and construction method thereof

A technology of clay core wall and anti-seepage wall, which is applied in basic structure engineering, wall dams, dams, etc., can solve the problems of flood difficulties in rainy seasons, high safety risks of deep foundation pits, restricting project construction period, etc., so as to improve construction safety. performance, avoid flood risks, and speed up construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

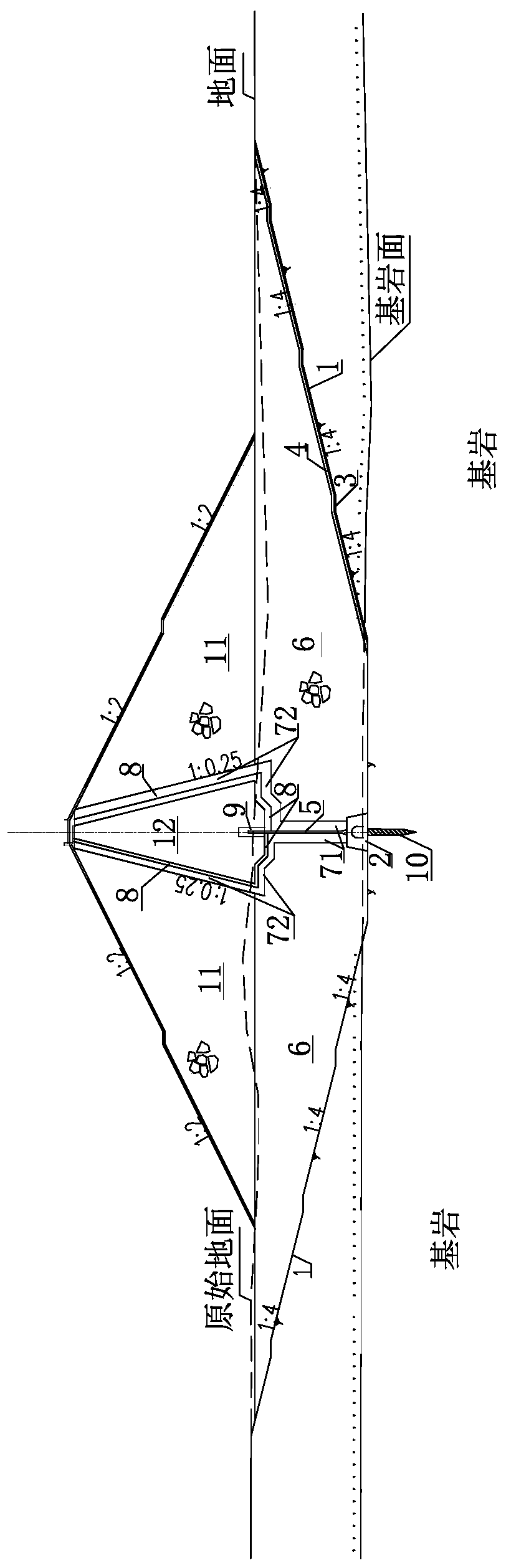

[0029] Refer to attached picture. The clay core wall dam structure provided by the present invention comprises a foundation pit 1, the foundation pit is deep to the bedrock, a grouting gallery 2 is arranged at the bottom of the foundation pit, and a curtain grouting 10 is arranged at the bottom of the grouting gallery 2; A cut-off wall 5 is set between the clay core walls 12, and a water-stop structure is set between the cut-off wall 5 and the grouting corridor 2. The elevation of the seepage wall 5 is higher than the rockfill backfill area 6; the clay core wall 12 is built on the rockfill backfill area 6, and the bottom of the clay core wall 12 is connected with the cut-off wall 5; the facing water of the clay core wall 12 The rockfill structure 11 of the dam is arranged outside the side and the backwater side, and the rockfill structure 11 of the dam is piled up on the rockfill backfill area of the foundation pit.

[0030] A transition material layer 71 is provided betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com