Column base joint with additional bending type damper capable of being replaced after earthquake

A column foot joint and damper technology, applied in the seismic field of structural engineering, can solve problems such as difficult maintenance after earthquake, and achieve the effects of improving seismic performance, easy replacement, and clear force transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

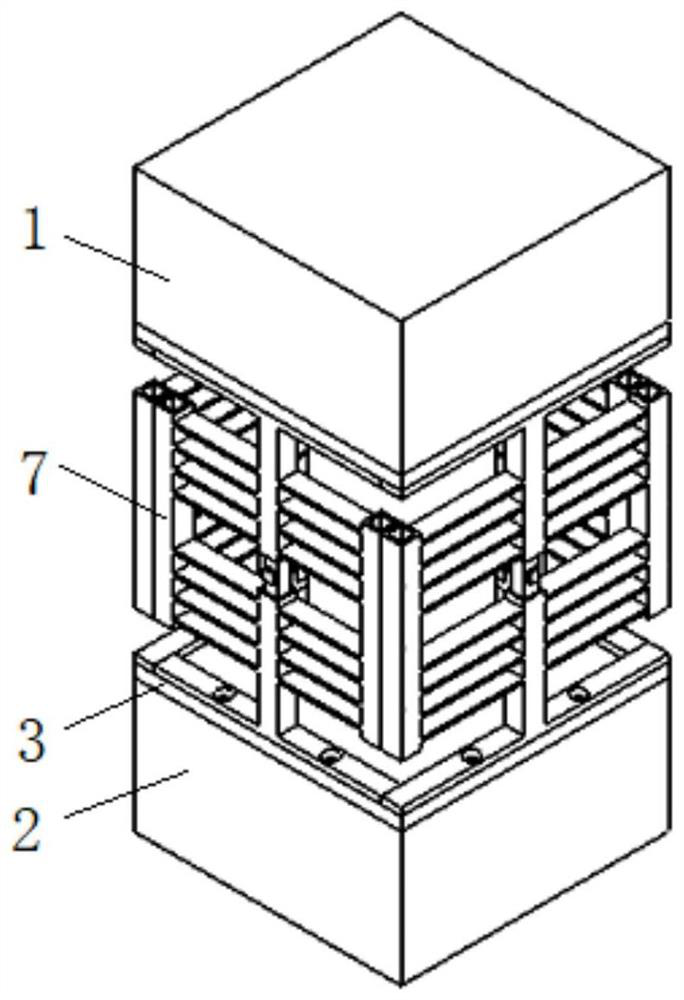

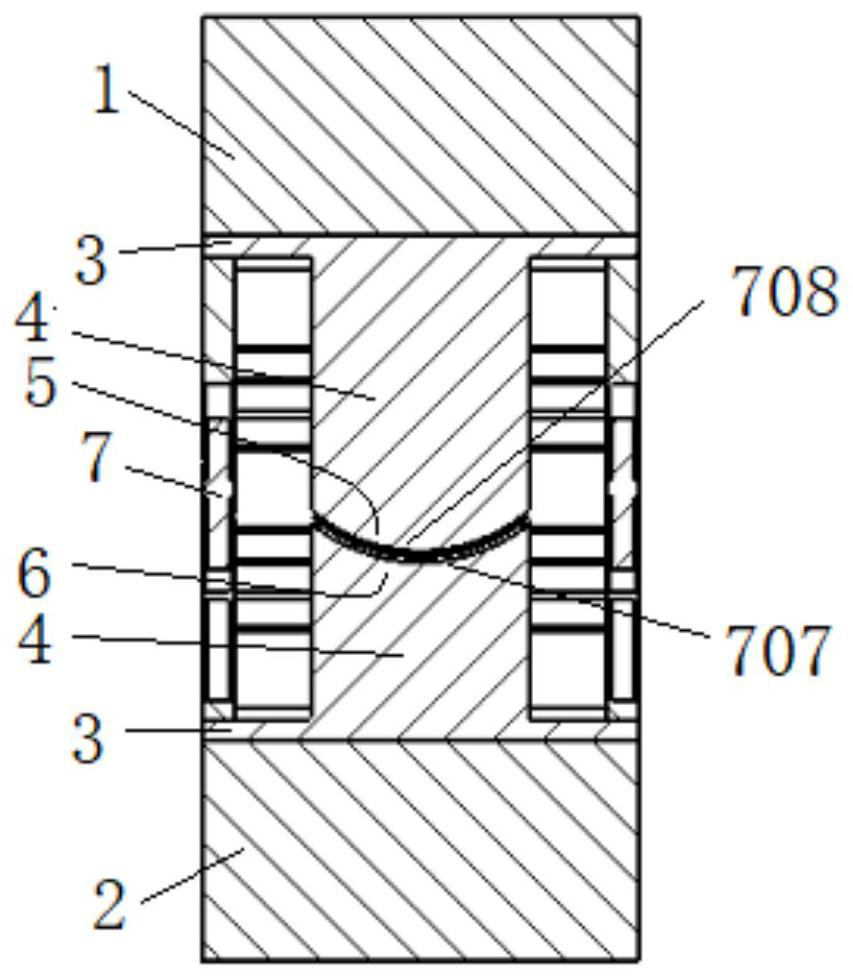

[0038] see Figure 1 to Figure 5 , is a column base node of a curved damper 7 that can be replaced after an additional earthquake, including upper column 1 and lower column 2 facing up and down, and bowls located at the axial centers of upper column 1 and lower column 2 and facing up and down shaped support 4, and the curved damper 7 surrounding the bowl-shaped support 4.

[0039] Specifically, the upper column 1 and the lower column 2 are both reinforced concrete square columns, and steel end plates 3 are respectively fixed on the cylindrical surfaces facing each other, and the centers of the two steel end plates 3 are respectively connected to steel bowl-shaped supports 4. Among them, the end surface of the bowl-shaped support 4 of the upper column 1 has an arc-shaped protrusion 5, and the end surface of the bowl-shaped support 4 of the lower column 2 has an arc-shaped groove 6, an arc-shaped protrusion 5 and an arc-shaped groove 6 to form a convex-concave arc-shaped matchi...

Embodiment 2

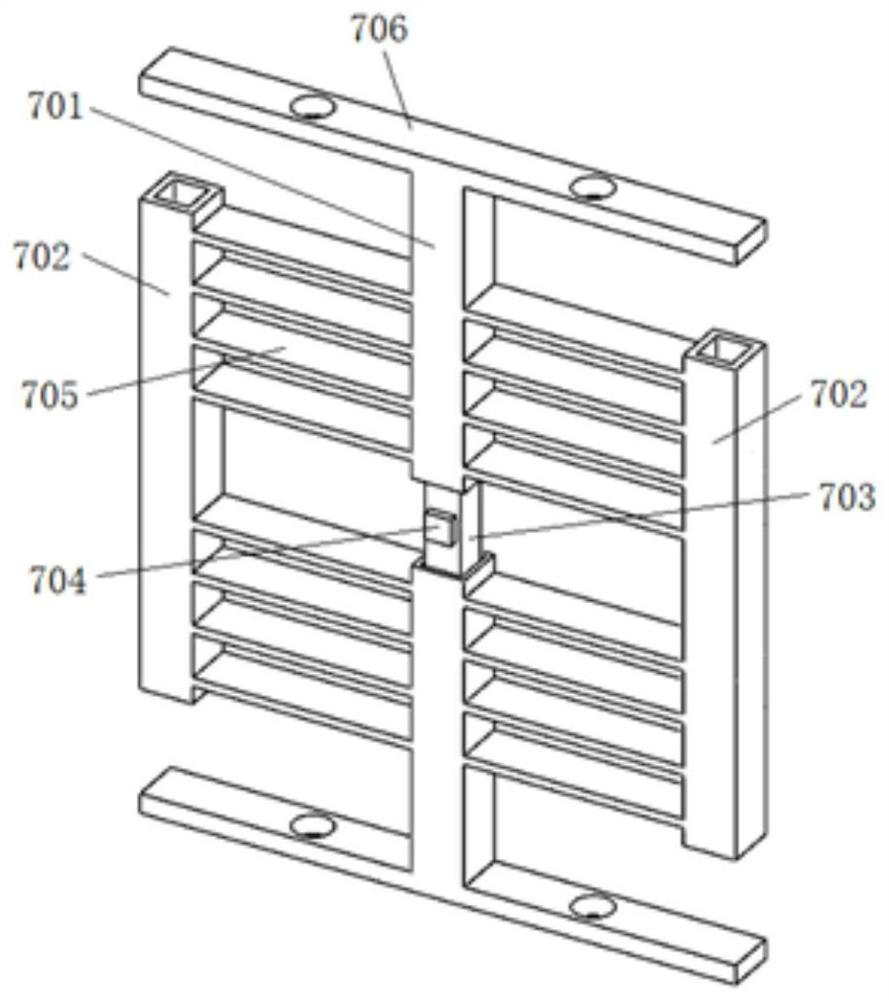

[0047] Such as Figure 6 As shown, the main difference between embodiment 2 and embodiment 1 is that the structure of the bending damper 7 is different. Specifically, each group of bending damper 7 includes an intermediate steel pipe section 701, which are respectively symmetrically arranged on two sides of the intermediate steel pipe section 701. The two side upper steel pipe sections 709 and the two side lower steel pipe sections 710, the two side upper steel pipe sections 709 and the two side lower steel pipe sections 710 are arranged correspondingly up and down on the same side, and the sides of the same side A connecting steel pipe section 703 is movably inserted between the upper steel pipe section 709 and the side lower steel pipe section 710, and a steel stopper 704 is provided on the connecting steel pipe section 703 to limit the axial position of the connecting steel pipe section 703. The middle steel pipe section 701 and the A group of curved plates 705 are respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com