Tuned mass damper with self-energy-dissipation vibrator

A technology for tuning mass damping and vibrators, applied in building components, building types, shockproof, etc., can solve problems such as engineering application reliability affecting product service life, large weight and structural size of electromagnetic damping devices, etc., to increase the effective mass ratio , reduce the total weight, increase the effect of vibration absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

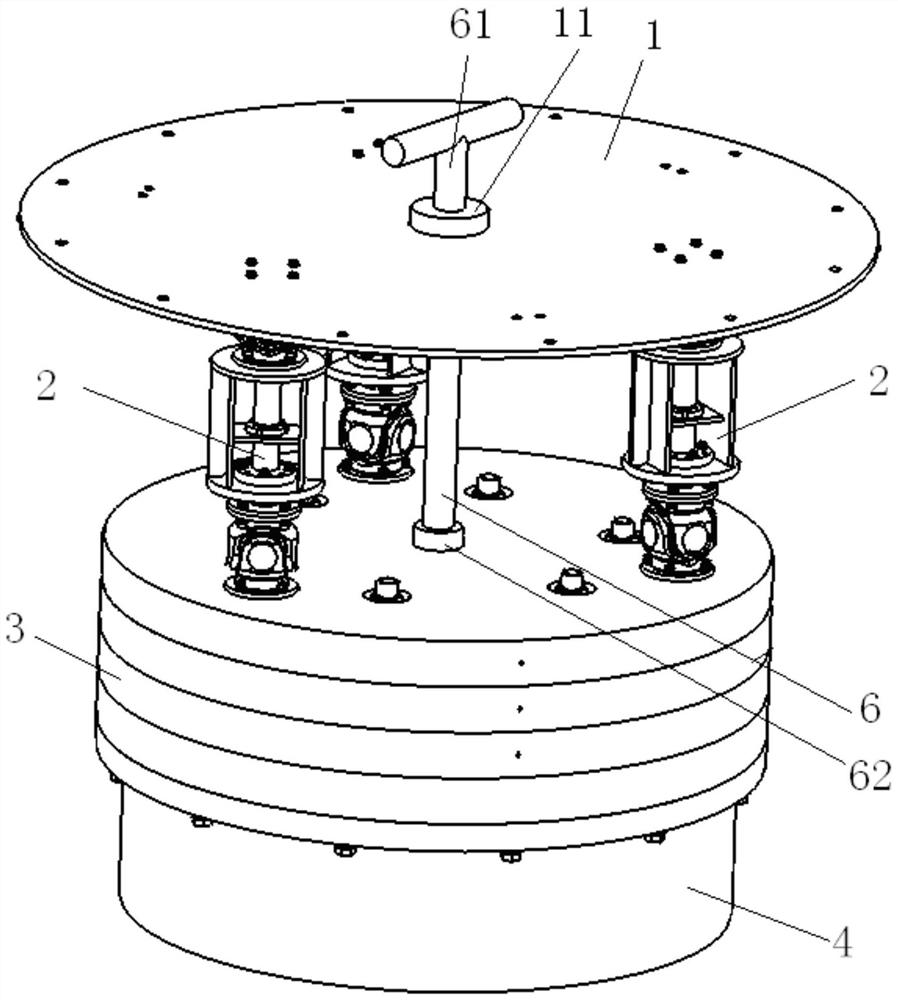

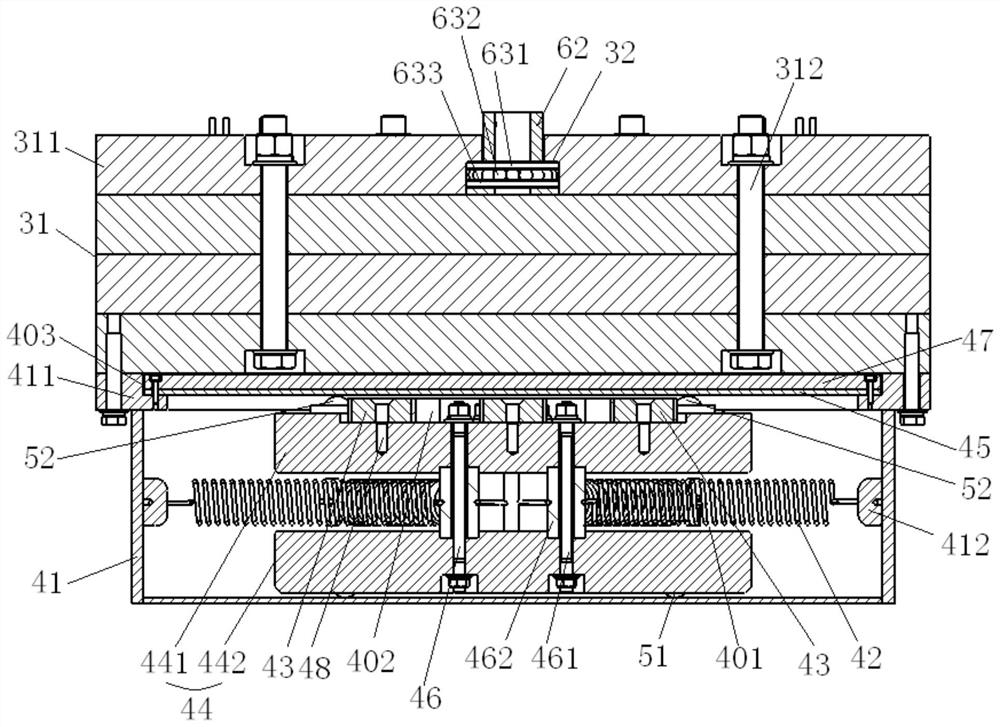

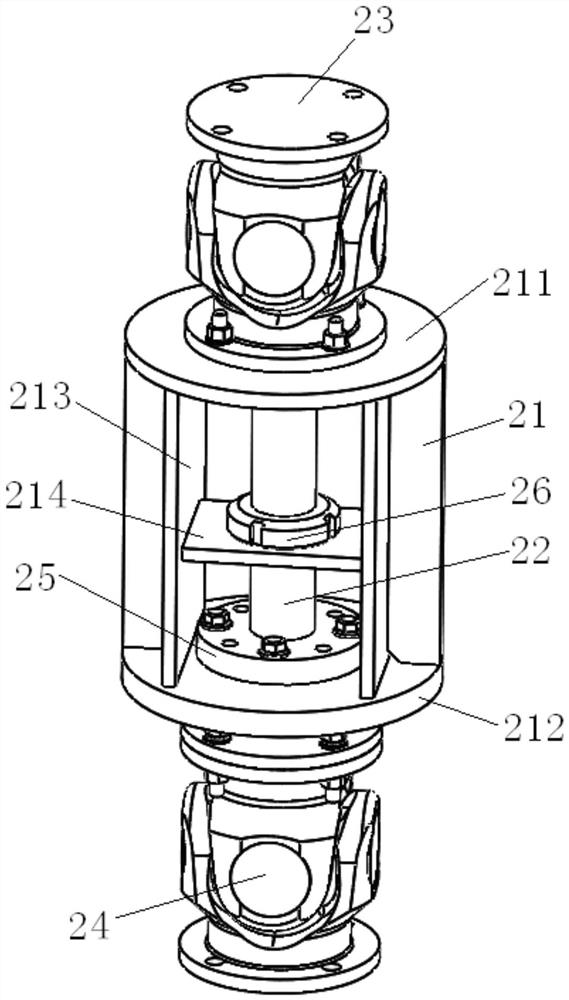

[0027] like figure 1 and figure 2 As shown, the tuned mass damper with self-consumption vibrator in this embodiment includes a load bearing plate 1, a swing rod assembly 2 and a self-consumption vibrator. The self-consumption vibrator includes a primary vibrator 3 and an energy dissipation device 4. The vibrator 3 includes a primary mass 31, the upper end of the swing rod assembly 2 is hinged to the bearing plate 1, and the lower end is hinged to the primary mass 31. The energy dissipation device 4 includes a housing 41, a tension spring 42, a magnetic steel 43, and a secondary vibrator 44 and a conductor plate 45, the top of the housing 41 is provided with a connection part 411, the connection part 411 is connected to the primary mass block 31, the conductor plate 45 is installed on the connection part 411, the tension spring 42, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com