Pipeline connecting structure

A connection structure and pipeline technology, applied in the direction of valve housing structure, sealing surface connection, pipe/pipe joint/pipe fitting, etc., can solve problems such as electric corrosion, potential difference at copper-aluminum connection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0036] Without loss of generality, this article takes the application of the pipeline connection structure in the connection between the shut-off valve and the pipeline as an example, and other similar applications are similar to this, and will not be described in detail.

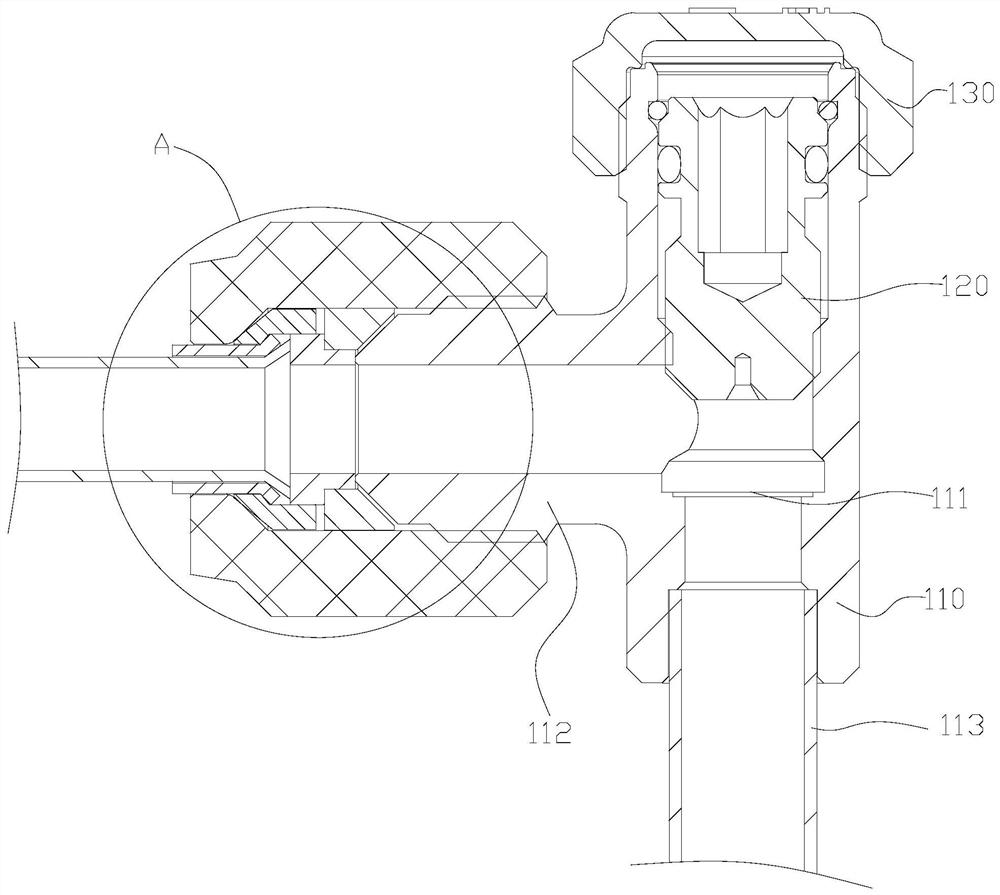

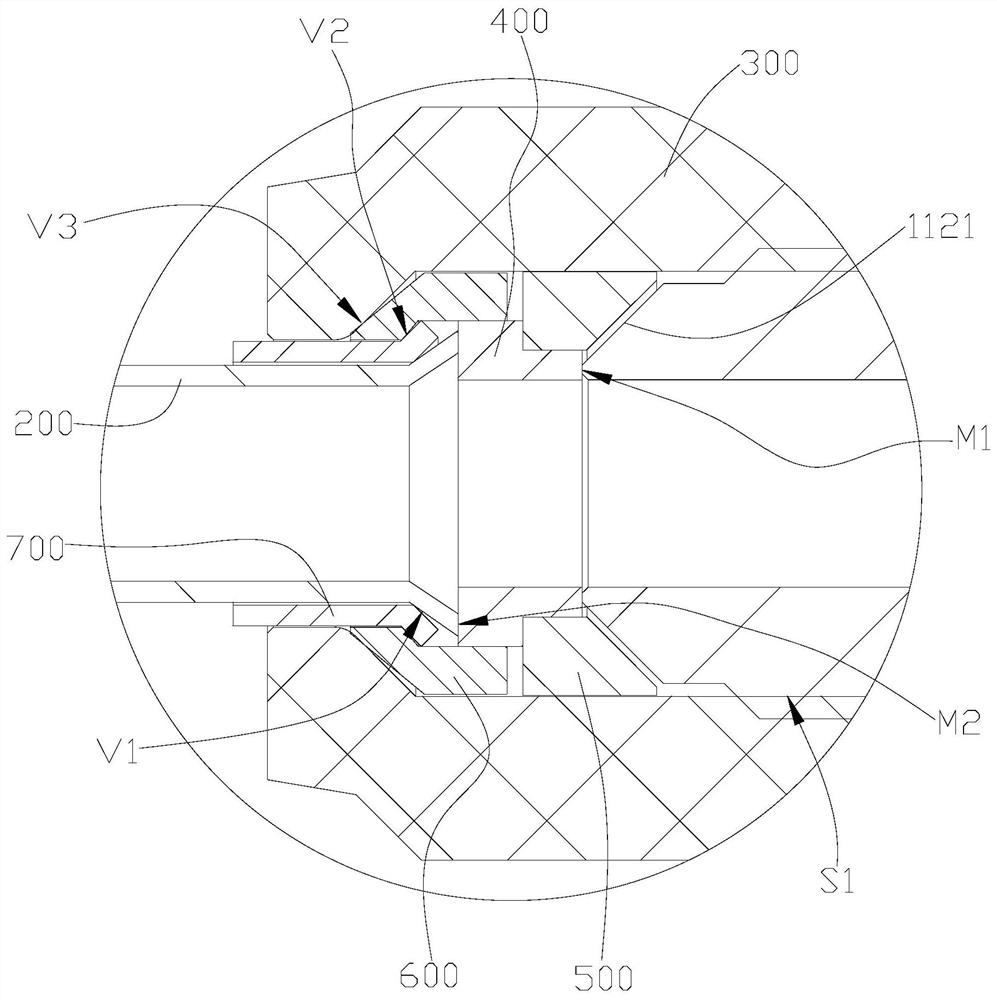

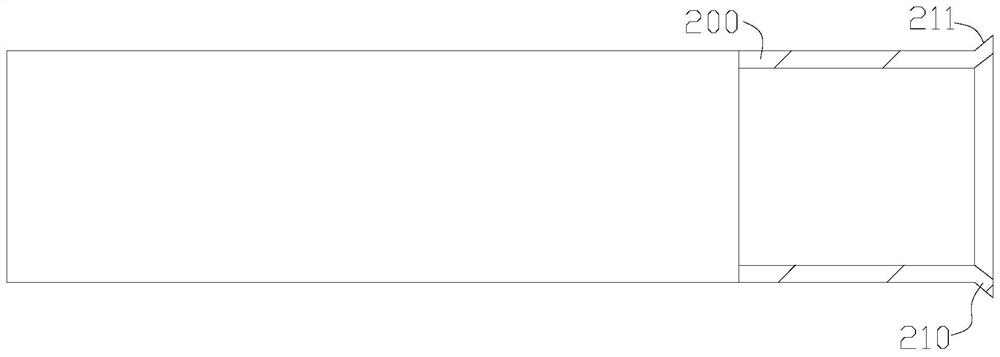

[0037] Please refer to figure 1 with figure 2 , figure 1 A schematic cross-sectional view of a specific embodiment of the connection structure between the shut-off valve and the pipeline provided by the present invention; figure 2 for figure 1 Partial enlarged view of part A in the middle.

[0038] The stop valve includes a valve body 110, a valve stem 120 and a bonnet 130; wherein, the side of the valve body 110 forms a valve body connecting portion 112 wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com