Automatic arrangement device for storage battery partition plates

A battery separator and automatic finishing technology, which is applied in battery assembly machines, secondary battery manufacturing, separators/films/diaphragms/spacers, etc., to ensure product qualification rate and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

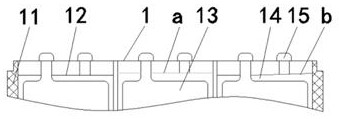

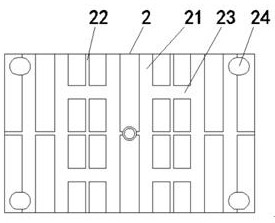

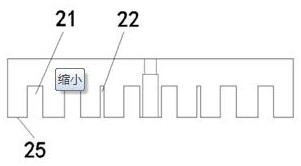

[0020] This embodiment provides an automatic sorting device for battery separators, such as figure 2 As shown, it mainly includes a frame and a lifting cylinder 4 and a positioning conveying mechanism 3 arranged on the frame. The telescoping rod of the lifting cylinder 4 is fixed with a sorting block 2 that matches the surface structure of the battery 1 that is not covered. like figure 2 and 3 The finishing block 2 is provided with a bus bar groove 21 matching with the bus bar 15 on the battery 1 and having a depth greater than the height of the bus bar 15, and a rib bar groove 22 matching with the rib on the battery 1 and having a depth greater than the height of the rib , a bridge groove 23 matching the bridge on the battery 1 and having a depth greater than the height of the bridge, and a pole avoidance hole 24 matching the pole on the battery 1 and having a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com