Heat generator using carbon NANO tube composite material

A technology of composite materials and carbon nanotubes, which is applied in the direction of carbon nanotubes, nanocarbons, heating element materials, etc., can solve the problems of low thermal efficiency of heating wires, increase the manufacturing process of heating wires, and limit the application range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

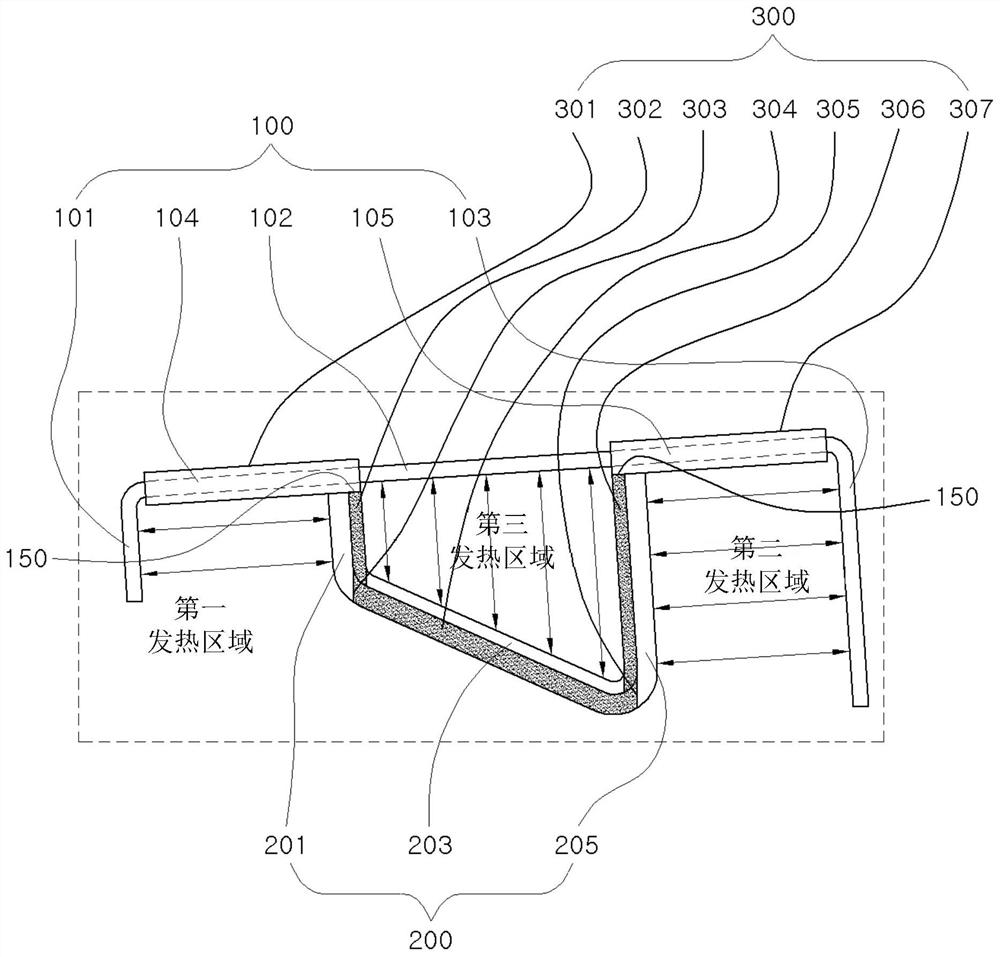

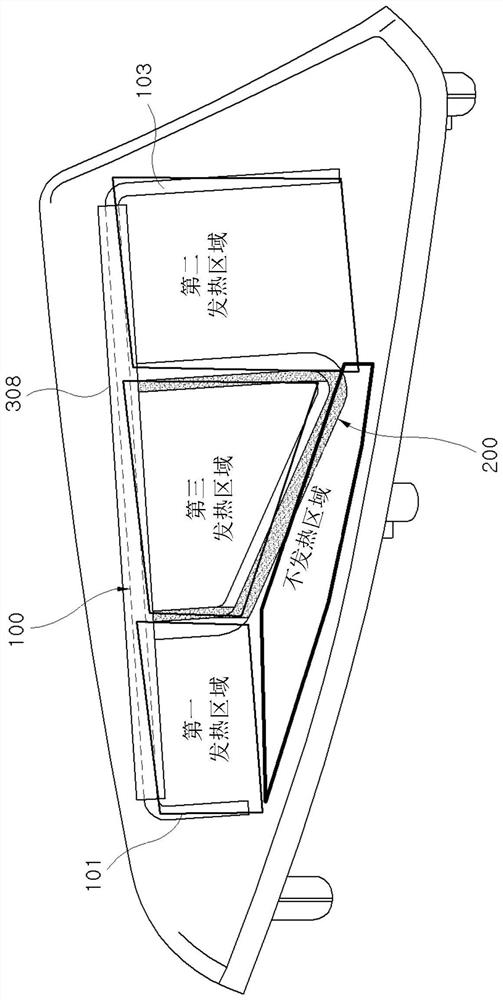

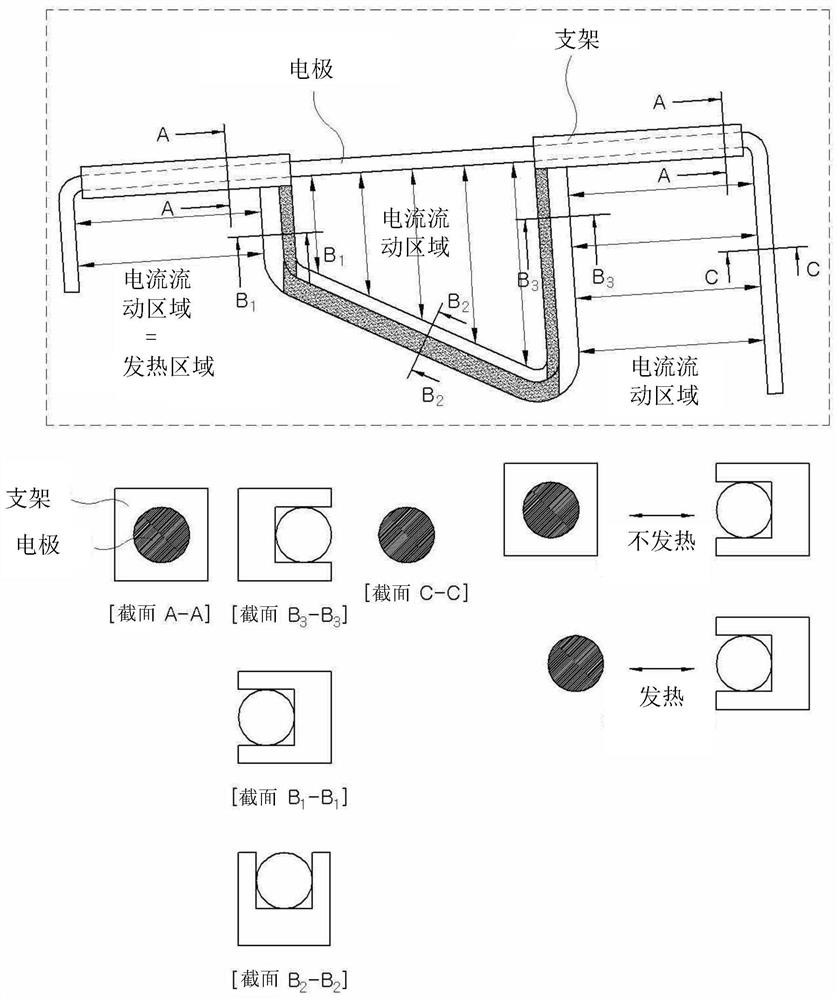

[0035] The invention may have various modifications and various embodiments, and specific embodiments are shown in the drawings and described in detail in the detailed description. However, it should be understood that this is not intended to limit the present invention to specific embodiments, but includes all modifications, equivalents and substitutions included within the spirit and technical scope of the present invention.

[0036] In describing each figure, like reference numerals are used for like components.

[0037] Terms such as first and second may be used to describe various components, but the components should not be limited by these terms. These terms are used only for the purpose of distinguishing one component from other components.

[0038] For example, a first component may be called a second component, and similarly, a second component may also be called a first component, without departing from the scope of the present invention. The term "and / or" include...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap