Centralized cooling oil cooling unit and control method

A control method and oil cooling technology, applied in refrigerators, refrigeration components, irreversible cycle compressors, etc., can solve the problems of high cost and heavy load, and achieve the effect of reducing production cost, reducing air conditioning load and saving space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

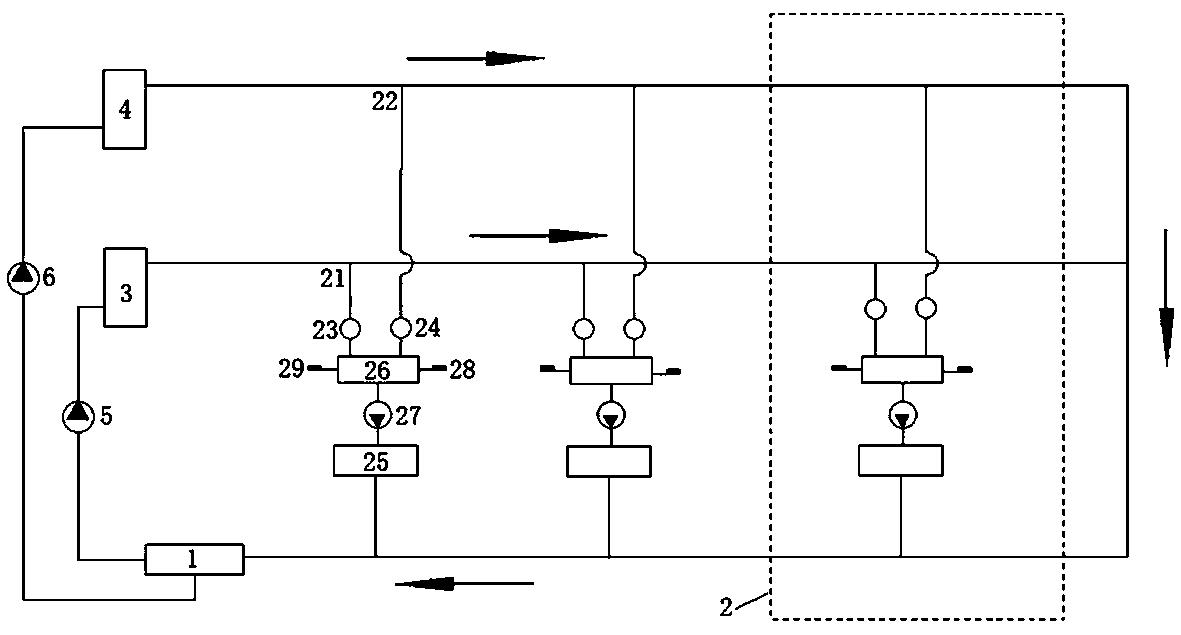

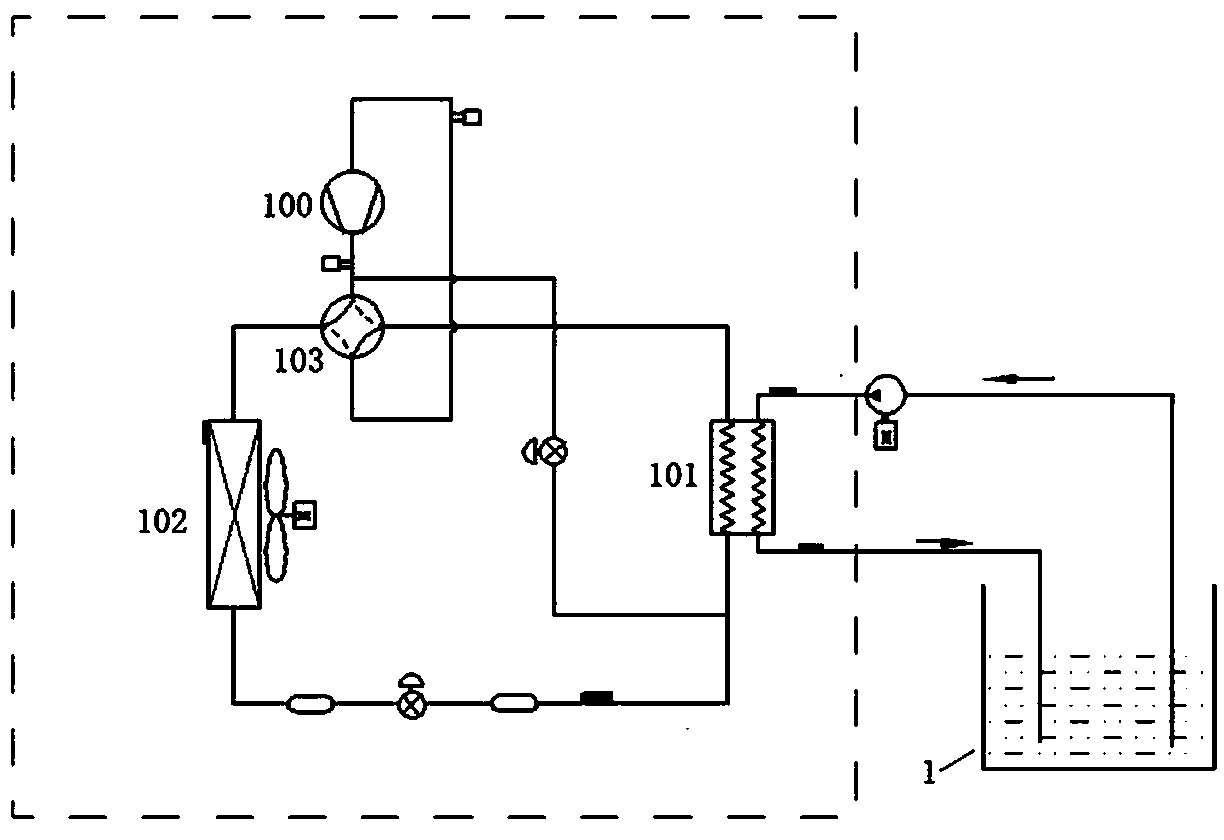

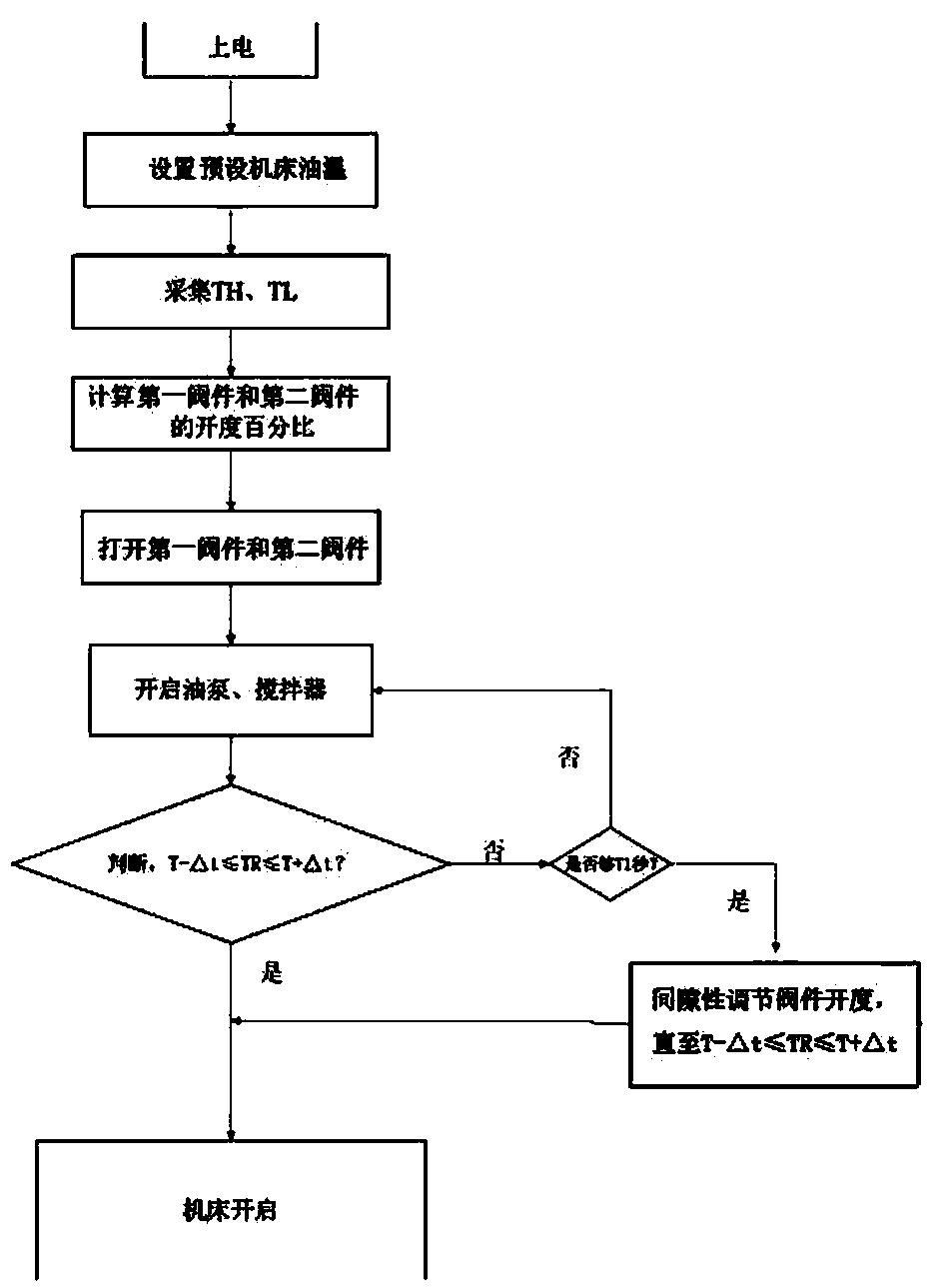

[0040] Such as figure 1 As shown, the preferred embodiment of the present invention proposes an oil cooling unit for centralized cooling, including: a total oil tank 1 and at least two machine tool oil circuits 2, the total oil tank 1 is connected with a first oil temperature regulating device 3 and a second oil temperature regulating device 3 arranged in parallel. Temperature regulating device 4. The first oil temperature adjustment device 3 provides cold oil, and the first oil pump 5 is connected in series between the main oil tank 1 and the first oil temperature adjustment device 3, and the first oil pump 5 sends the oil in the main oil tank 1 to the first oil temperature adjustment device 3 to lower the temperature, and the first oil temperature regulating device 3 controls the outlet oil temperature to the temperature TL. The second oil temperature regulating device 4 provides hot oil, and the second oil pump 6 is connected in series between the total oil tank 1 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com