Rotary drum type pitting machine

A rotary drum and frame technology, applied in the field of rotary drum type corers, can solve the problems of crawler type corers occupying a large space, unable to maintain a consistent posture, and not suitable for small and medium-sized enterprises, etc., and achieves compact structure and adaptability. Good sex, little vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The specific content of the present invention will be further explained in detail below in conjunction with the examples.

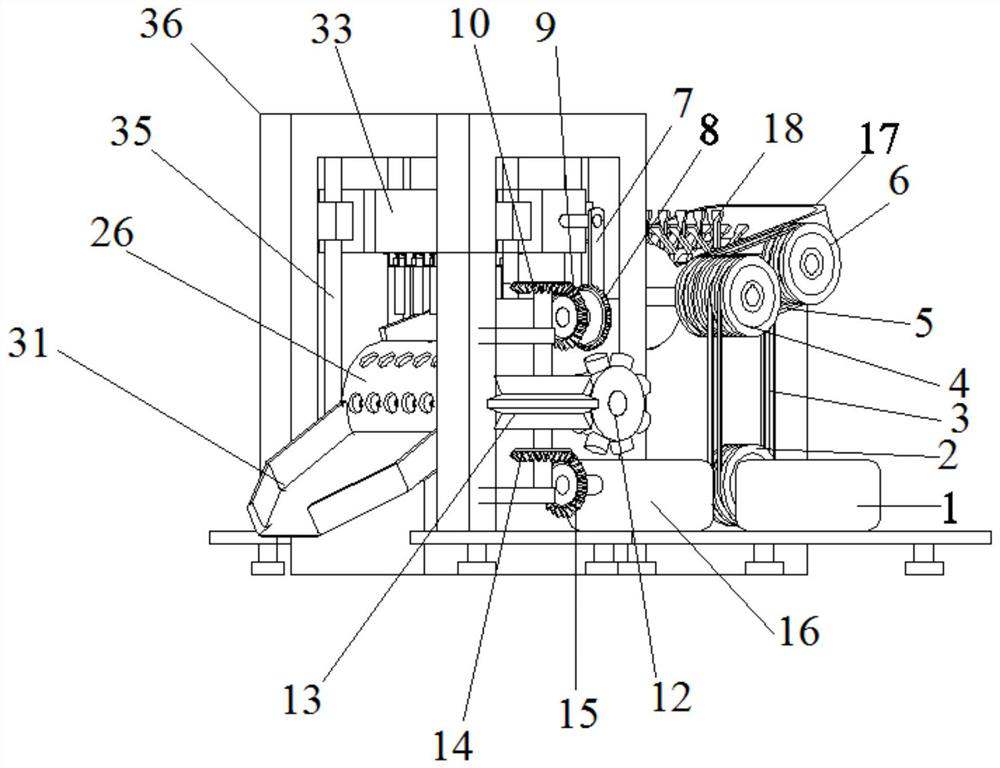

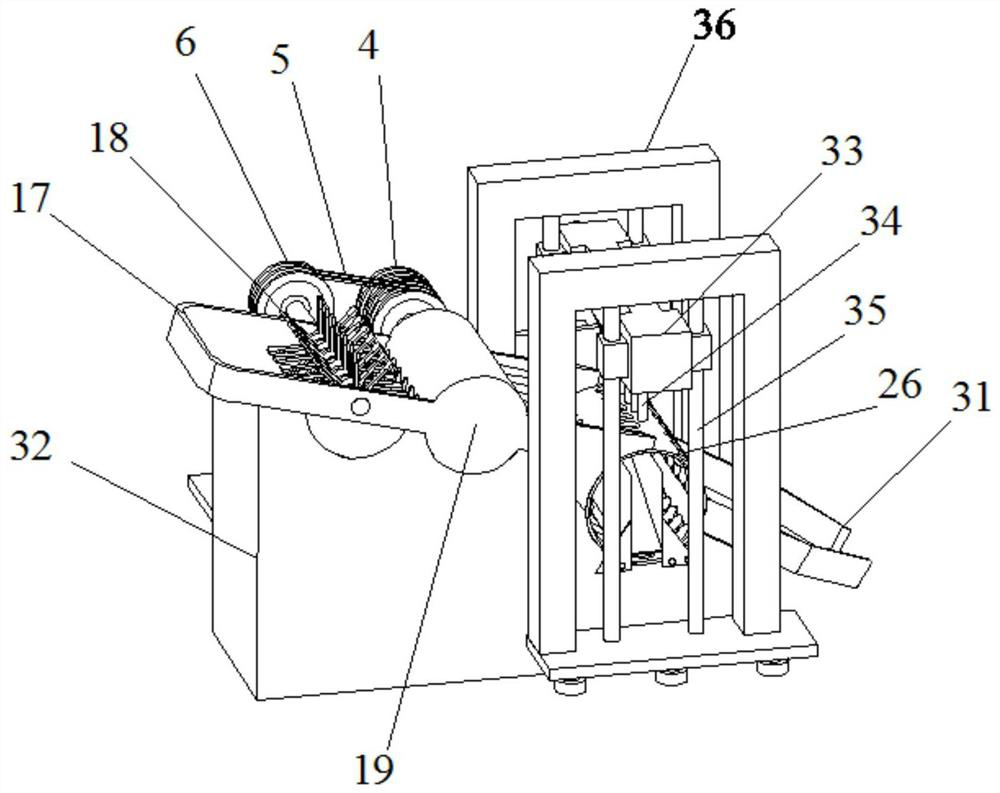

[0048] Such as Figure 1-Figure 3 As shown, the present invention provides a drum-type nuclear remover, comprising a frame 32, the top of the frame 32 is an inclined surface from top to bottom, the angle between the inclined surface and the horizontal plane is 20°, and the inclined surface is set There is a feeding mechanism.

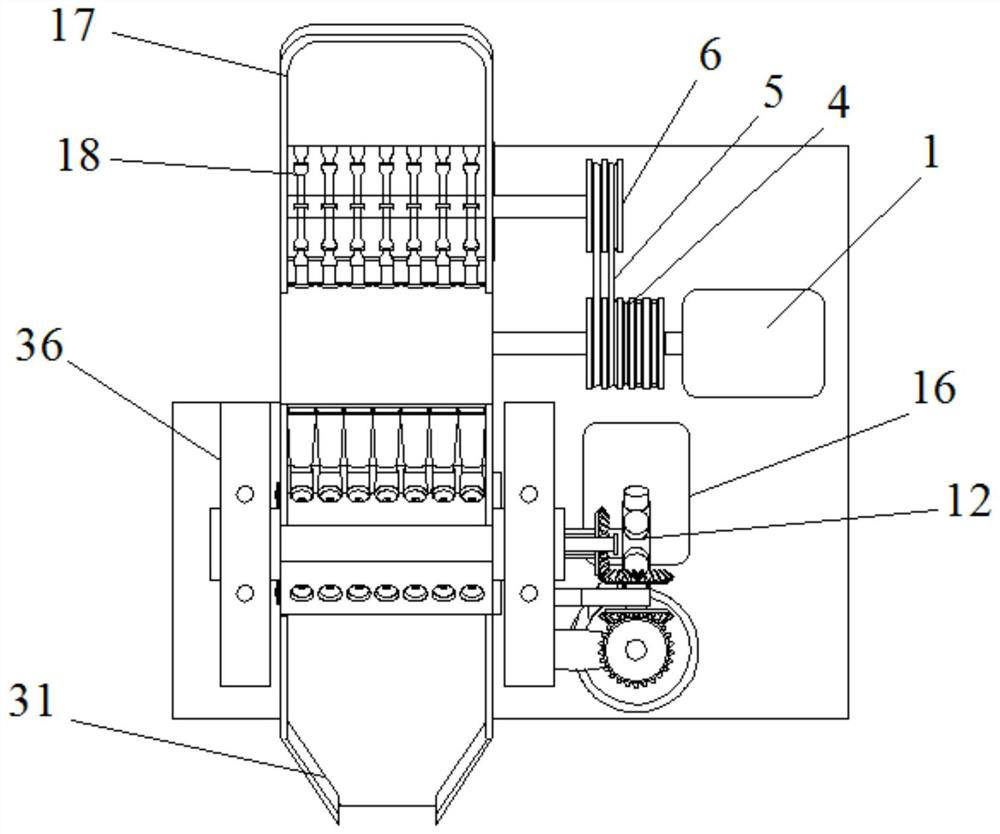

[0049] refer to Figure 4-Figure 6 , the feeding mechanism includes a feeding tray 17 that is matched and installed on the inclined surface. The feeding tray 17 includes a chassis that matches the inclined surface and a baffle plate welded to the upper edge of the chassis. An arc-shaped first groove and an arc-shaped second groove, the first groove is located in the third groove provided on the frame 32, and the second groove is located in the fourth groove provided on the frame 32; The baffle is U-shaped and the U-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com