Edible fungus preparation method

A technology of edible fungi and processing equipment, which is applied in the direction of chemical instruments and methods, applications, food processing, etc., can solve the problems of edible fungus damage, easy crushing of edible fungi, and low efficiency, so as to improve production efficiency, save manpower and material resources, Clean up for full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

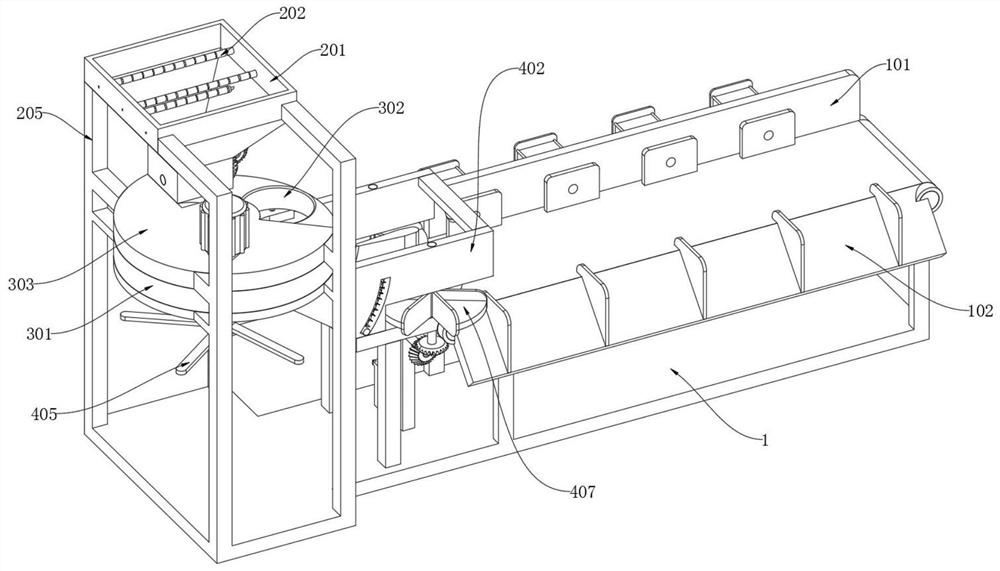

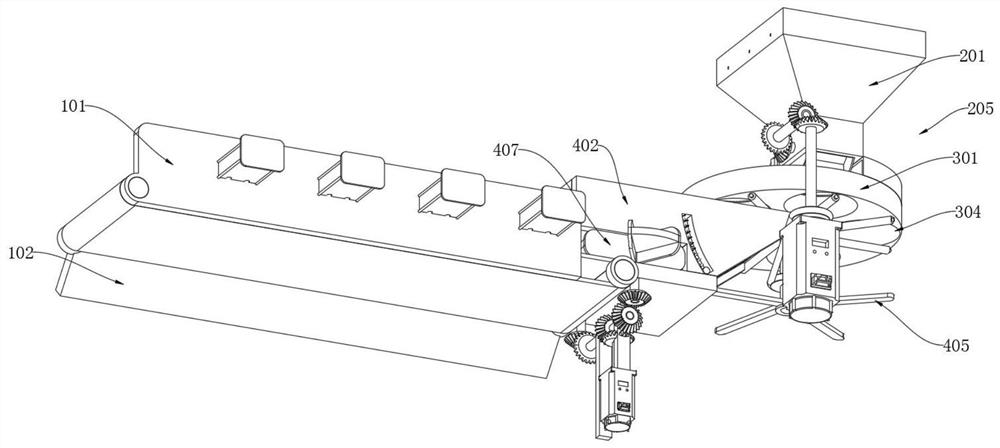

[0033] as attached figure 1 to attach Figure 8 Shown:

[0034] The present invention provides a method for preparing edible fungi. The preparation method of edible fungi is completed by using special processing equipment for edible fungi, thereby realizing efficient preparation of edible fungi; the special processing equipment for edible fungi includes:

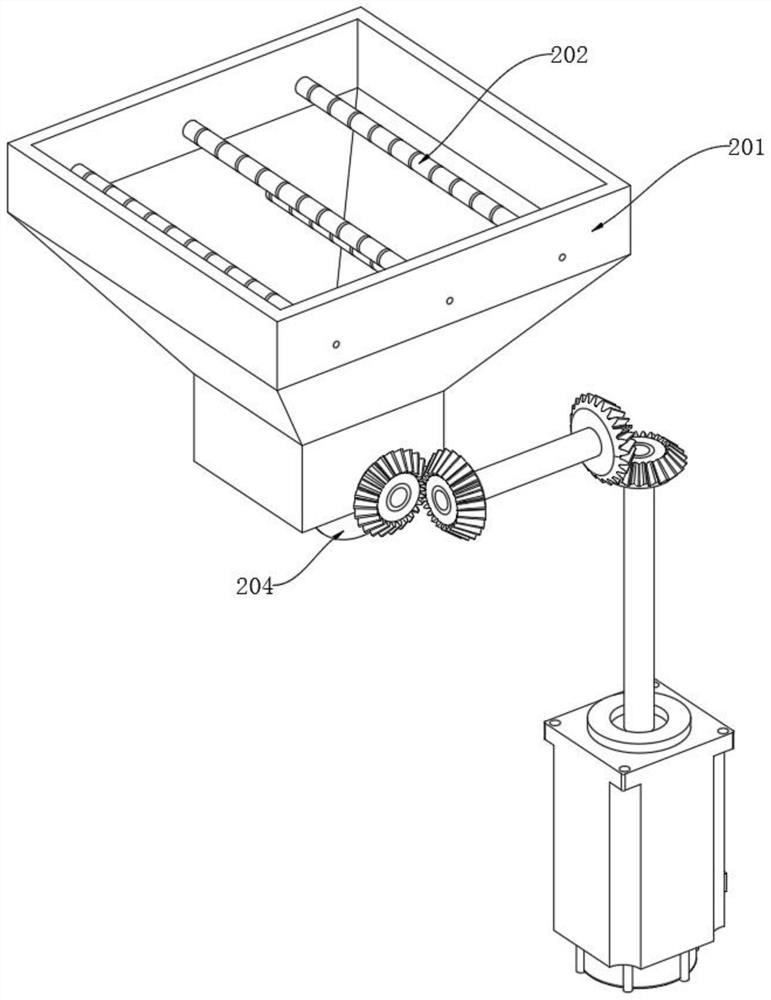

[0035] Main body 1, a motor is installed on the top of the main body 1, a bevel gear is installed on the top of the motor, and a feeding part 2 is installed on the top of the main body 1; feeding part 2, the bracket 205 in the feeding part 2 is installed on the top of the main body 1 , and a motor is installed on the side of the support 205, a bevel gear is installed on the top of the motor, and a cleaning part 3 is installed on the bottom of the feed part 2; the cleaning part 3; the cover plate 303 in the cleaning part 3 is installed on the side of the support 205, And the vertical bar 305 in the cleaning part 3 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com