Automatic scissors device and automatic hair cutting method

A scissors, automatic technology, applied in grain processing and other directions, can solve the problem of inconvenient cleaning and replacement, and achieve the effect of convenient disassembly, quick installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

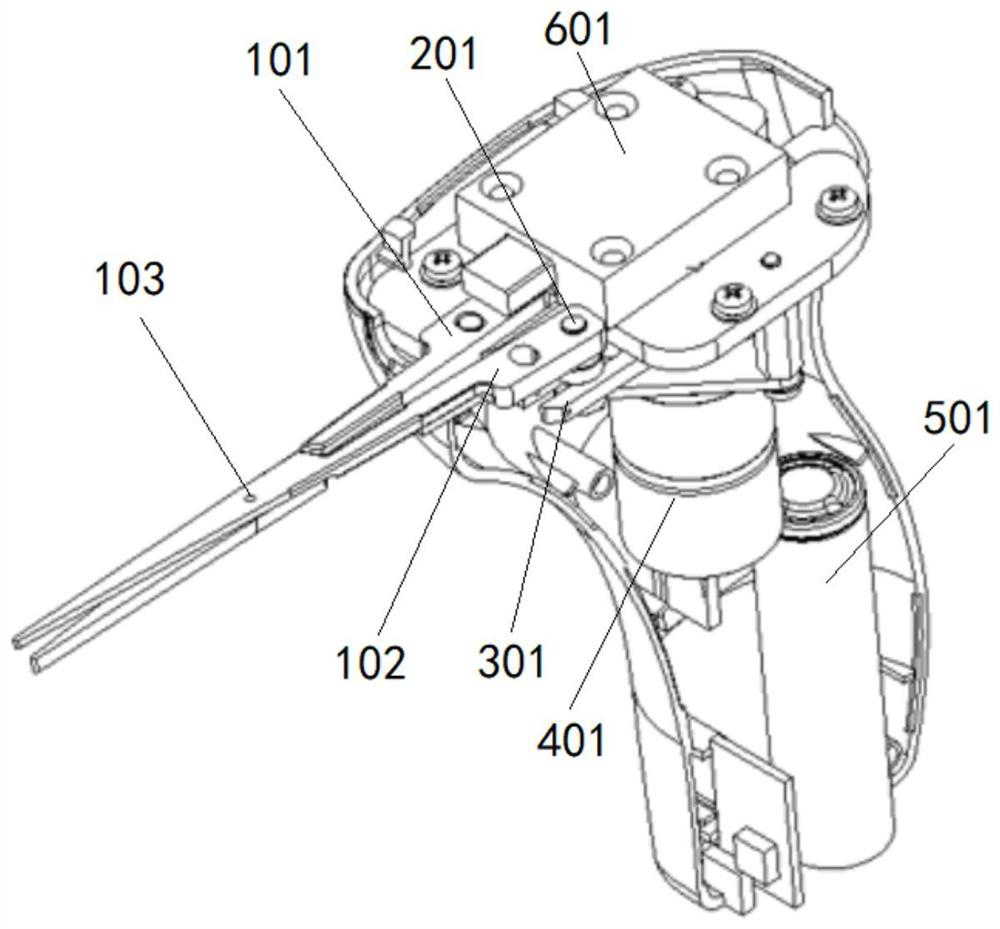

[0031] figure 1 Schematically provides the structural diagram of the automatic scissors device of embodiment 1 of the present invention, as figure 1 Shown, described automatic scissors device comprises:

[0032] Scissors and a bracket, the scissors include a rotating shaft 103, a first operating handle 101 and a second operating handle 102, and the second operating handle 102 rotates around the rotating shaft;

[0033] a fixing unit 601, the fixing unit is used for fixing the first operating handle 101;

[0034] A rotating shaft 302, the rotating shaft 302 is fixed on the bracket;

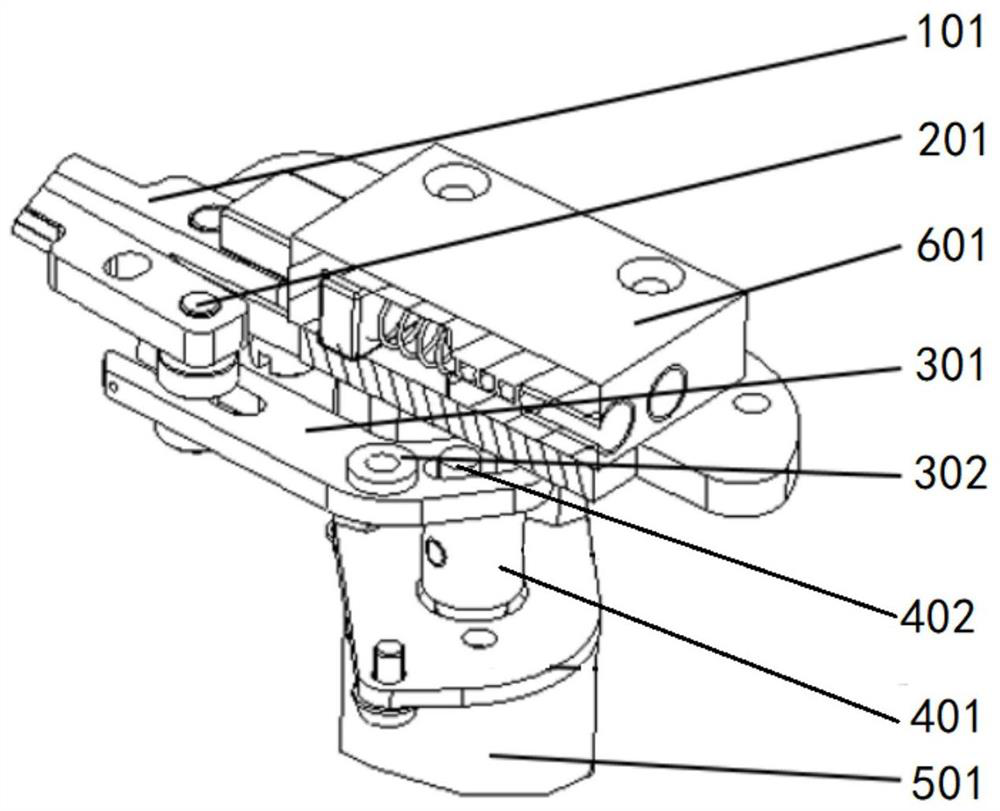

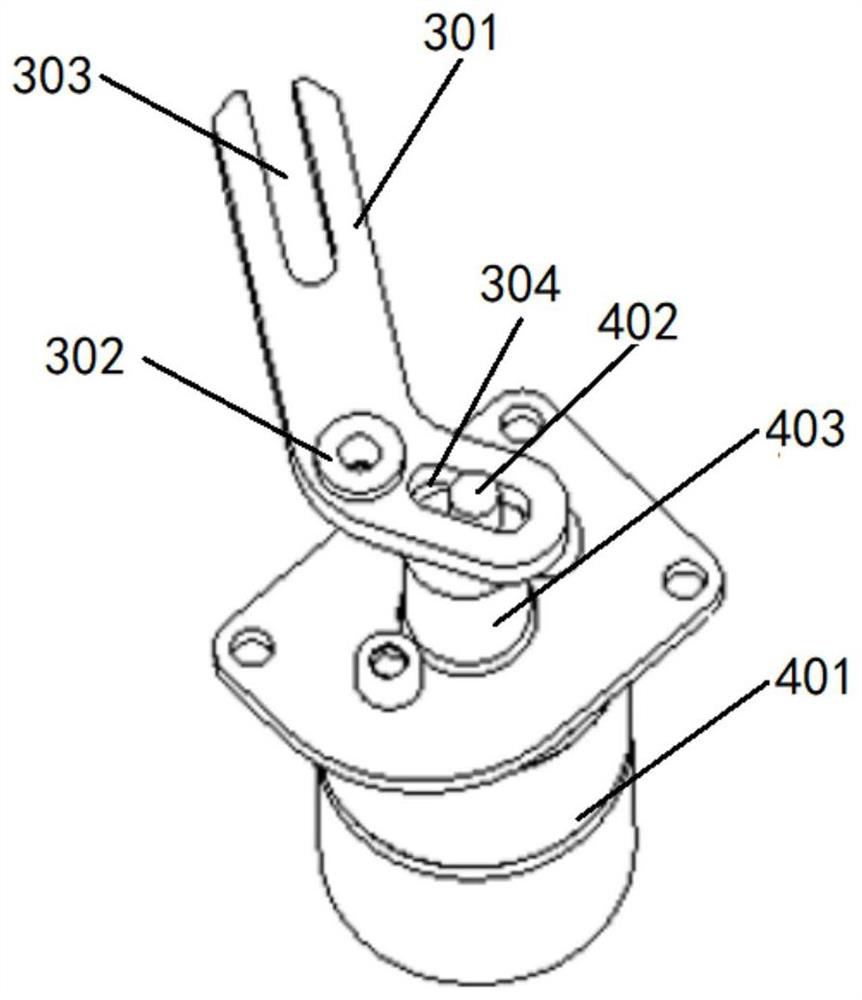

[0035] swivel arm 301, such as Figure 2-3 As shown, the rotating arm 301 has a first hole 303 and a second hole 304;

[0036] The first column 201 and the second column 402, the first column 201 is fixed on the second operating handle 102, and is suitable for sliding in the first hole 303; the second column 402 is fixed on the drive unit 601, and is suitable for sliding in the second hole 304...

Embodiment 2

[0058] An application example of the automatic scissors device and the automatic hair cutting method according to Embodiment 1 of the present invention.

[0059] In this application example, if figure 1 As shown, the automatic scissors device is in the shape of a pistol; the first operating handle 101 is fixed on the fixing unit 601, and the second operating handle 102 rotates around the rotating shaft 103;

[0060] Such as Figure 2-3 As shown, the rotating arm 301 includes a first part and a second part, and the angle between the first part and the second part is an obtuse angle; the rotating shaft 302 passes through the connecting part between the first part and the second part; A hole 303 is set on the first part, and a second hole 304 is set on the second part; the first column 201 is fixed on the second operating handle 102 and is suitable for sliding in the first hole 303; the second The column 402 is fixed on the driving unit and is suitable for sliding in the second...

Embodiment 3

[0077] According to the application example of the automatic scissors device of embodiment 1 of the present invention and the automatic cutting method of hair, different from embodiment 2 is:

[0078] A linear guide rail is provided, the angle between the extension direction of the linear guide rail and the extension direction of the second hole is not zero; the second column is arranged on the linear guide rail and moves linearly forward and reverse along the linear guide rail ;

[0079] The drive unit adopts a linear movement mechanism to drive the second column to move forward and reverse linearly on the linear guide rail, thereby driving the rotating arm to rotate around the rotation axis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com