Ink supply circulation system capable of preventing ink from precipitating

A circulation system and ink supply technology, which is applied to mixers with rotating stirring devices, mixers, fixed filter elements, etc., can solve the problems of easy clogging of nozzles, large dosage, and insufficient color, and avoid clogging of nozzles , Avoid ink precipitation, smooth inkjet effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

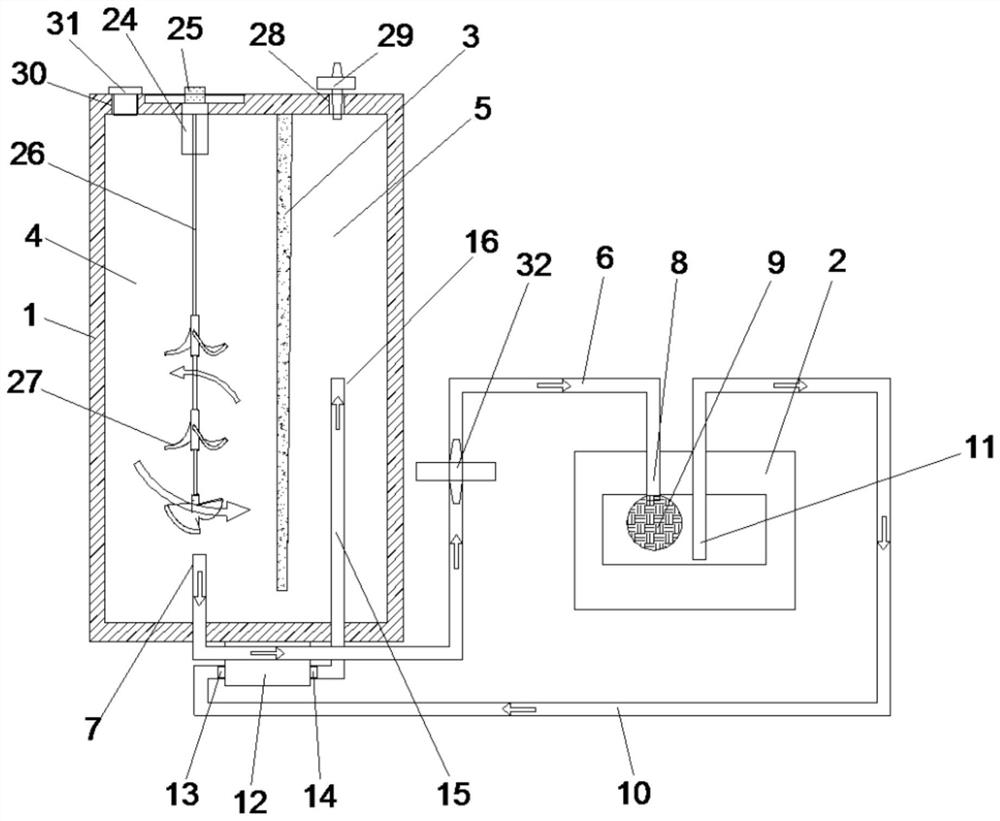

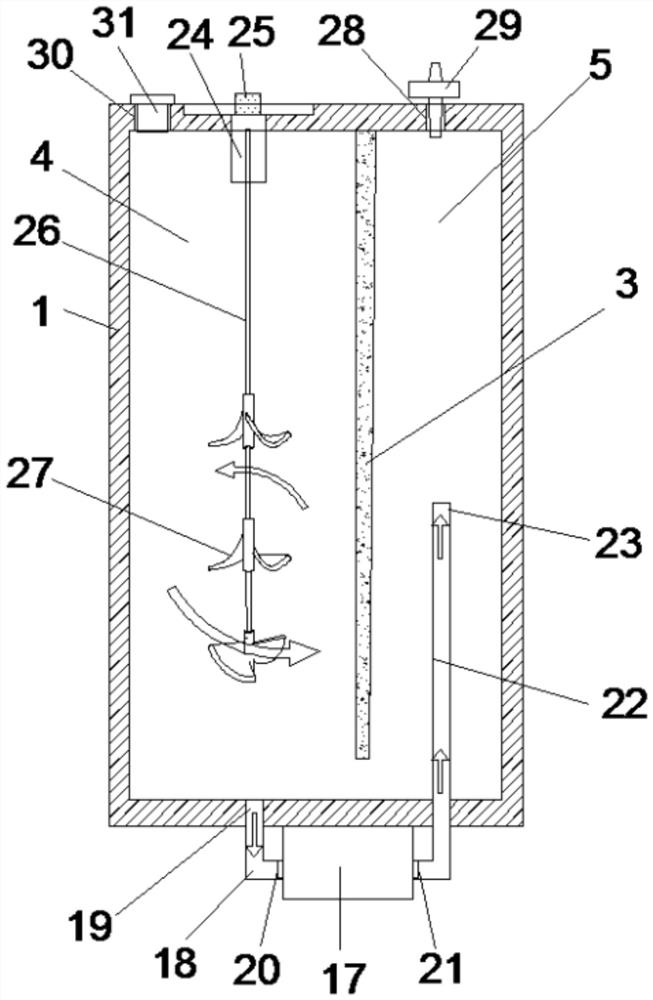

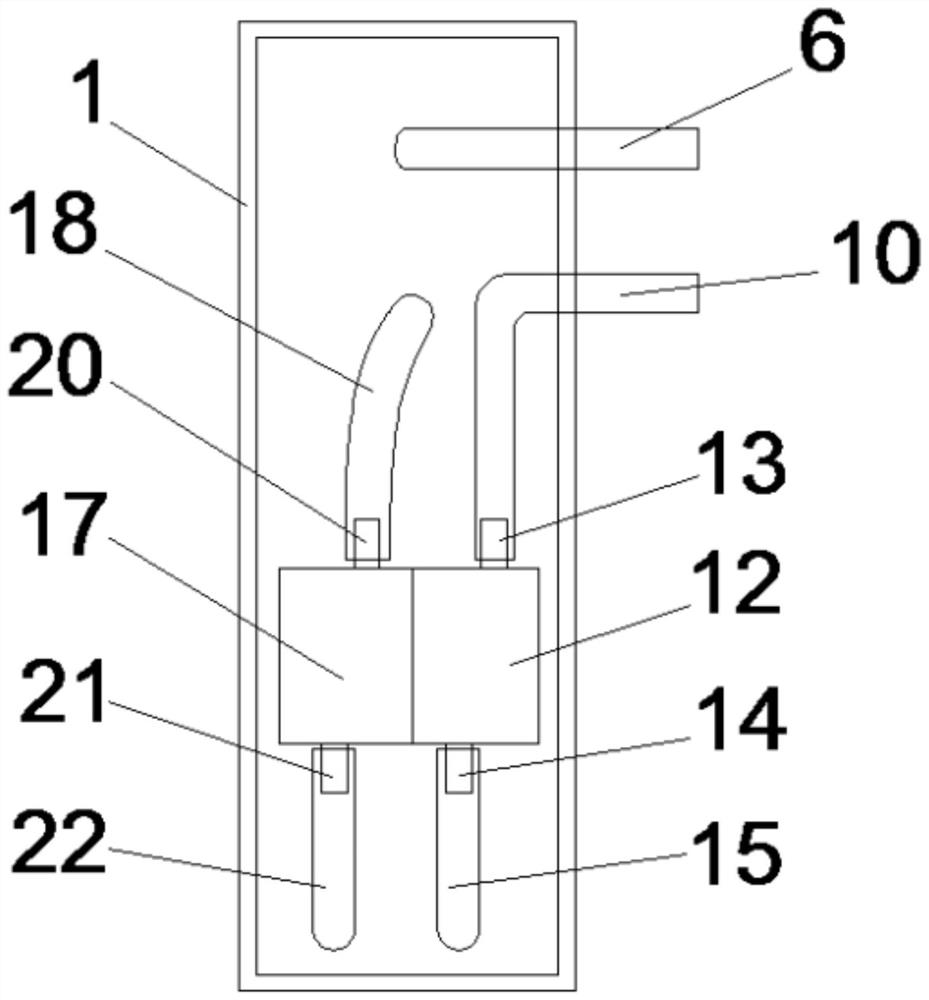

[0026] Example 1: See Figure 1-5 , the present invention provides a technical solution: an ink supply circulation system that prevents ink from settling, including an ink tank 1 and an ink bag 2, and the inner cavity of the ink tank 1 is divided into a main tank area 4 by a partition plate 3 and the auxiliary chamber area 5, the main chamber area 4 communicates with the bottom of the auxiliary chamber area 5, the main chamber area 4 communicates with the ink bag 2 through the first circulation pipe 6, and the first circulation pipe 6 is provided with Extending to the A1 port 7 in the main chamber area 4, the first circulation pipe 6 is provided with an A2 port 8 extending into the ink bag 2, and the A2 port 8 is equipped with a metal filter 9. The ink bag 2 is communicated with a second circulation pipe 10, the second circulation pipe 10 is provided with a B1 port 11 extending to the bottom of the ink bag 2, and the bottom of the ink tank 1 is equipped with a first circulatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com