Automatic packing machine and packing method

An automatic and wrapping technology, applied in the direction of automatic packaging control, packaging, packaging protection, etc., can solve the problems of inability to adjust the packaging angle, inability to bundle in multiple directions, etc., and achieve the effects of easy programming, high action repeatability, and simple procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

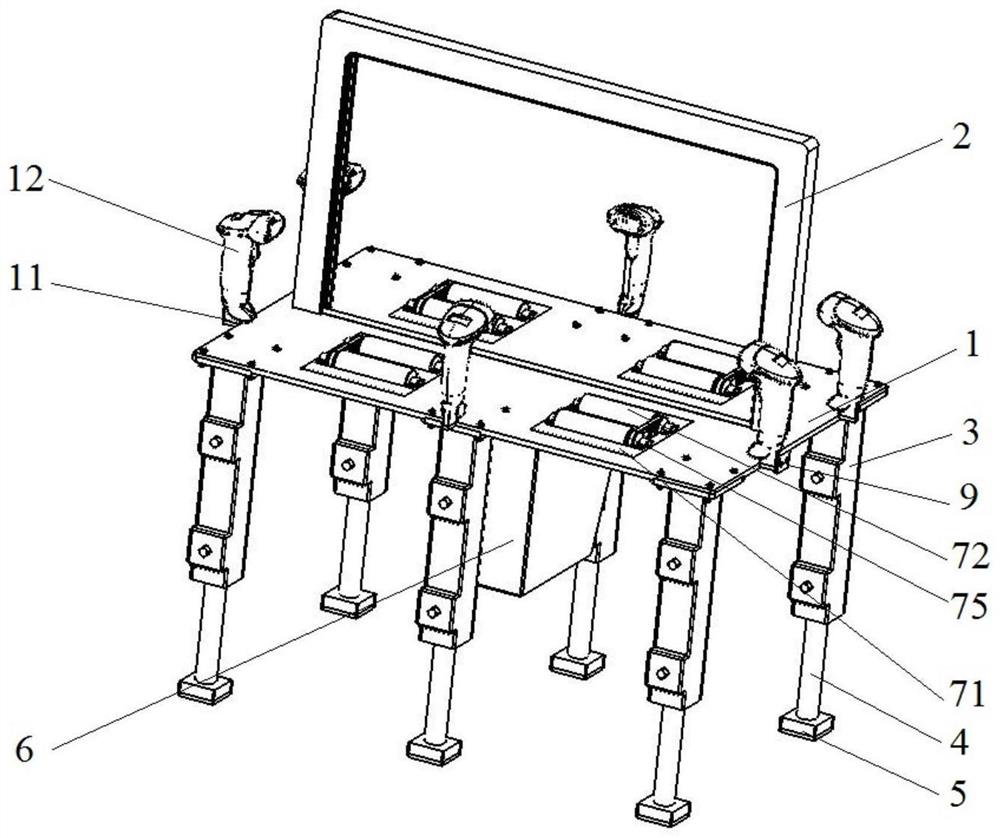

[0039] Such as Figure 1-4 As shown, a kind of automatic baler provided by the present invention includes a workbench 1, a belt guide groove 2 and supporting legs 3, and four roller modules 7 are arranged on the workbench 1, and the roller modules 7 are arranged in pairs, symmetrically arranged on the guide On both sides of the belt slot 2, the four sides of the workbench 1 are equipped with a code scanning gun mounting frame 11. The code scanning gun mounting frame 11 is hinged on the edge of the working table 1. The code scanning gun 12 is installed on the code scanning gun mounting frame 11. The gun mounting frame 11 is reversed downwards, so that the code scanning gun 12 can be reversed under the table of the workbench 1 to avoid the transport position of the parcel.

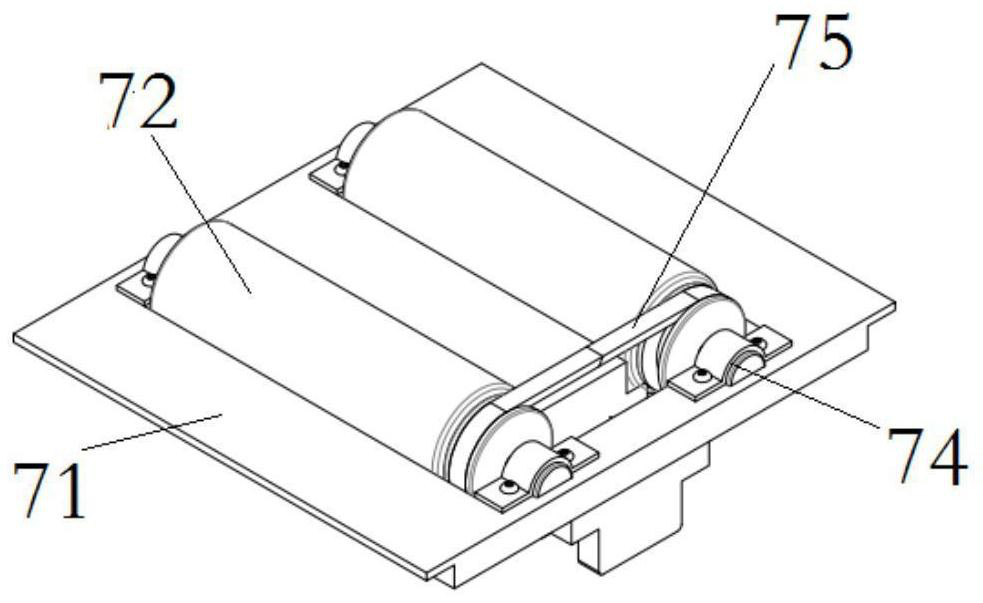

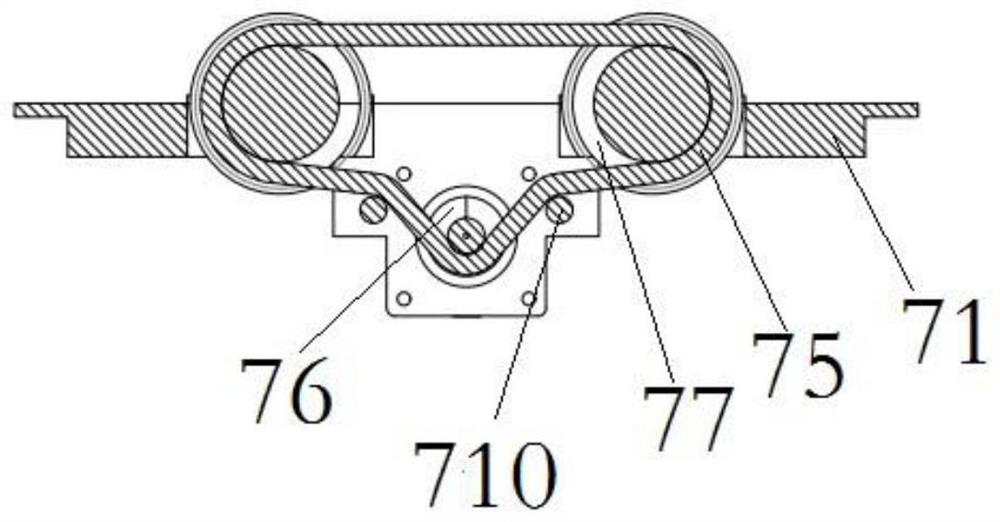

[0040] The roller module 7 includes a roller base 71, a roller 72, a roller bearing cap 74 and a roller bearing 78. The roller base 71 is provided with two side-by-side penetrating square grooves, and semici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com