A light-cutting filter, its preparation method and application

A technology of cut-off filter and filter, applied in the field of materials, can solve the problems of affecting the macroscopic uniformity of the filter, residual metal and etchant, affecting the filter performance, etc., and achieve good thermal stability and chemical stability. , the effect of improving macroscopic uniformity and good hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

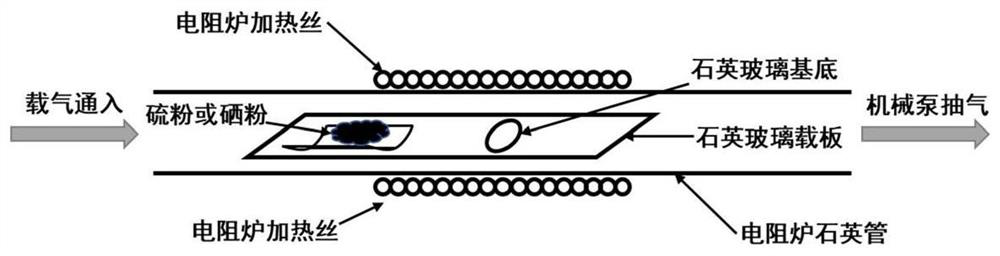

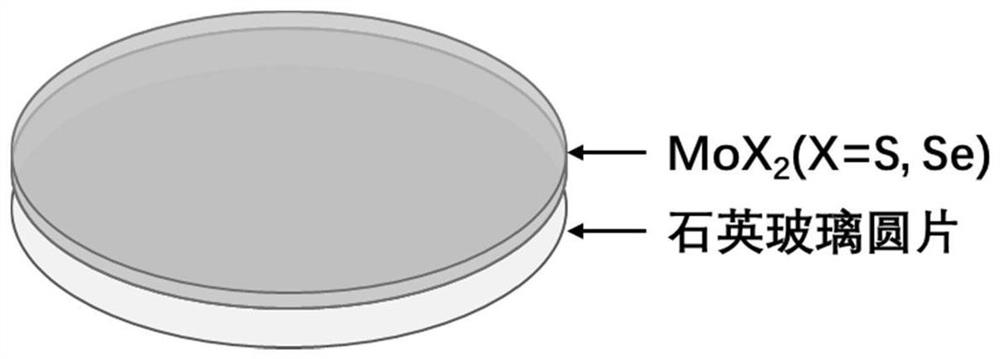

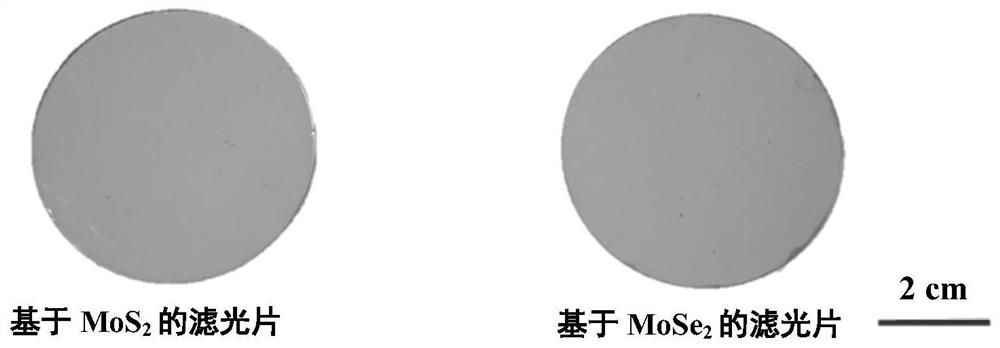

[0041] combine figure 1 Instructions are based on MoX 2 (X=S,Se) filter preparation process. Quartz glass wafer after cleaning by magnetron sputtering coating method A layer of 10nm thick molybdenum film is deposited on the surface (or directly purchase a quartz glass wafer of the corresponding size coated with molybdenum film), and the quartz glass coated with molybdenum film is cleaned again, as the growth MoX 2 (X=S,Se) substrate (hereinafter referred to as growth substrate). The growth substrate was placed on a quartz glass carrier plate, and the carrier plate together with the growth substrate was placed in the middle of a three-inch single-temperature zone tube furnace, and sulfur powder or selenium powder was placed upstream as a transforming agent. For MoS 2 For the preparation of , the sulfur powder is 12-18 cm away from the growth substrate, while for MoSe 2 The selenium powder is 8-10 cm away from the growth substrate.

[0042] in MoS 2 In the preparation pr...

Embodiment 2

[0047] combine Image 6 The fabrication process of the h-BN-based filter is described. The cleaned quartz glass disc On a long quartz carrier plate, place the quartz carrier plate together with the quartz glass sheet in the center of the temperature zone of the three-inch three-temperature zone tube furnace. Weigh about 0.3 g of borane ammonia (BH 3 —NH 3 ) is placed in a small tube, the small tube is connected to the branch of the tee interface at the air inlet, 65-75 cm from the furnace body, heated with a self-made heating belt, and the reaction system is evacuated to 35-55Pa by a rotary vane mechanical vacuum pump . During the preparation of h-BN, a mixed gas consisting of 150 sccm of argon and 100 sccm of hydrogen was introduced into the reaction system as a carrier gas, and the tube furnace was heated to 1100 °C within 70 min and stabilized at a constant temperature of 1100 °C for about 30 min , turn on the self-made heater to heat the borane ammonia to about 85 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com