Evaporation support plate, evaporation device and evaporation method

A technology of evaporation and carrier plate, which is applied in the directions of vacuum evaporation plating, sputtering plating, ion implantation plating, etc., can solve the problems of mask plate deformation and affecting the evaporation effect, etc., to improve the precision and improve the evaporation efficiency. The effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

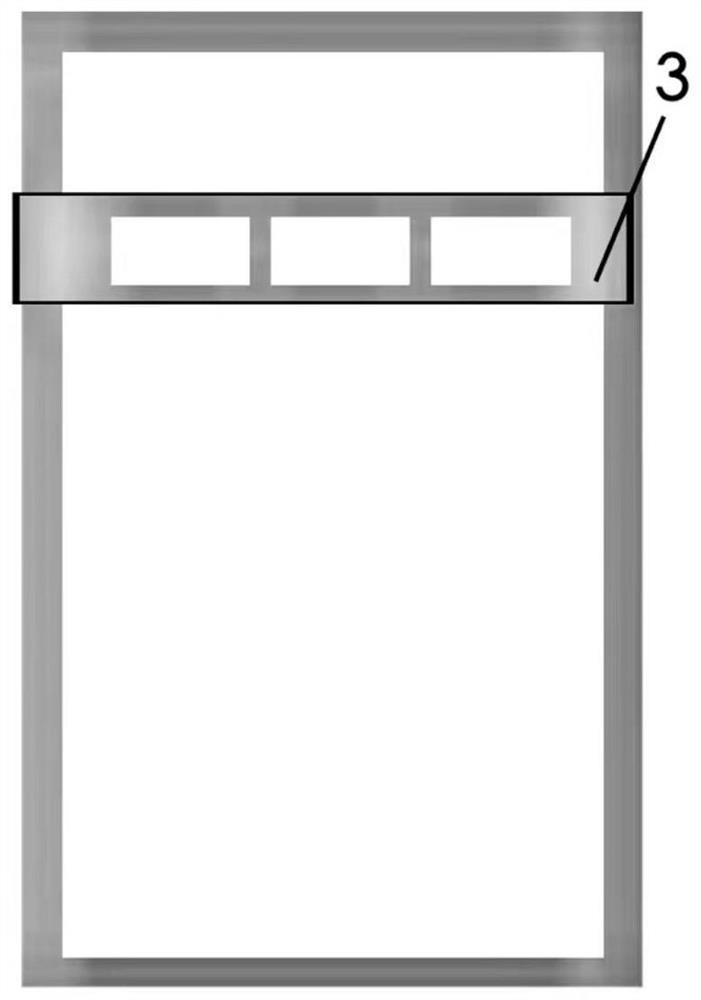

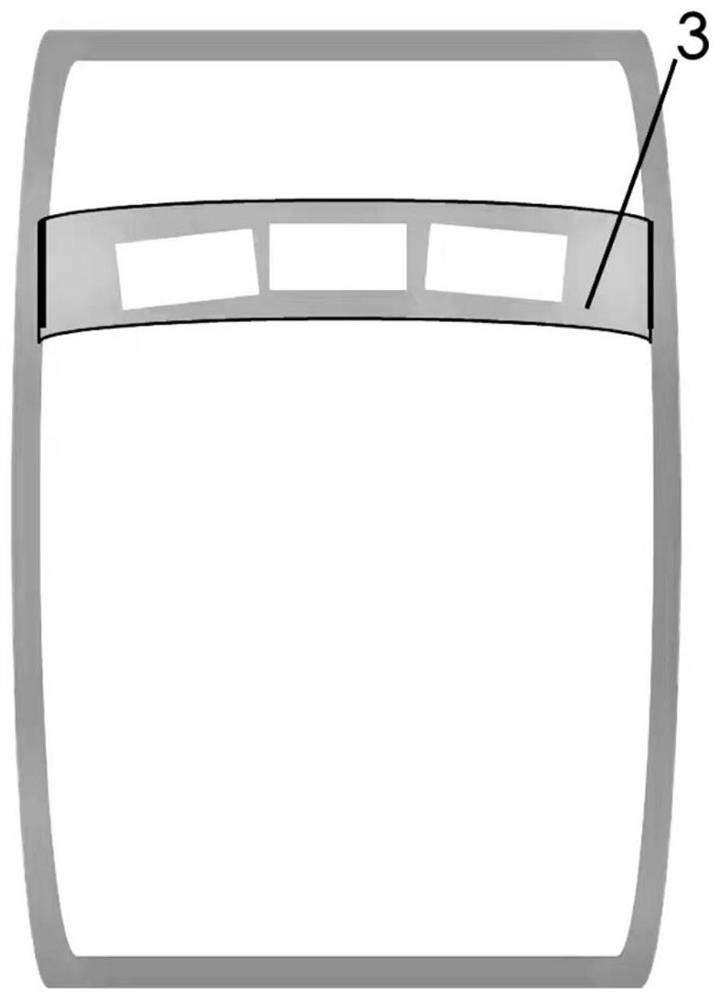

[0030] Before entering the vapor deposition machine, the mask plate 3 in the normal temperature state is square, such as Figure 1a As shown, during evaporation, when the mask plate 3 is used for a period of time, due to the increase of the evaporation temperature, the mask plate 3 itself will expand to a certain extent, causing the diaphragm strips on the mask plate 3 to no longer be square. (Such as Figure 1b shown), the glass substrate entering the evaporation chamber at this time, such as Figure 1c As shown, if the temperature of the glass is not compensated, its deformation does not match the Mask deformation. Even if the position is matched, the evaporation offset in some areas will exceed the standard, which will lead to display defects and affect product yield. . At present, the method that the deformation of the mask plate under high temperature affects the evaporation effect is generally to compensate the expansion deformation into the netting of the mask plate 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com