Sliding type aluminum alloy handrail cleaning mechanism and cleaning method thereof

A cleaning mechanism, aluminum alloy technology, applied in cleaning methods, road surface cleaning, construction, etc., can solve problems such as railings that consume a lot of manpower and material resources, easy to fall with a lot of dust and impurities, and high labor intensity, so as to improve the cleaning effect and facilitate Multi-wipe, strength-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

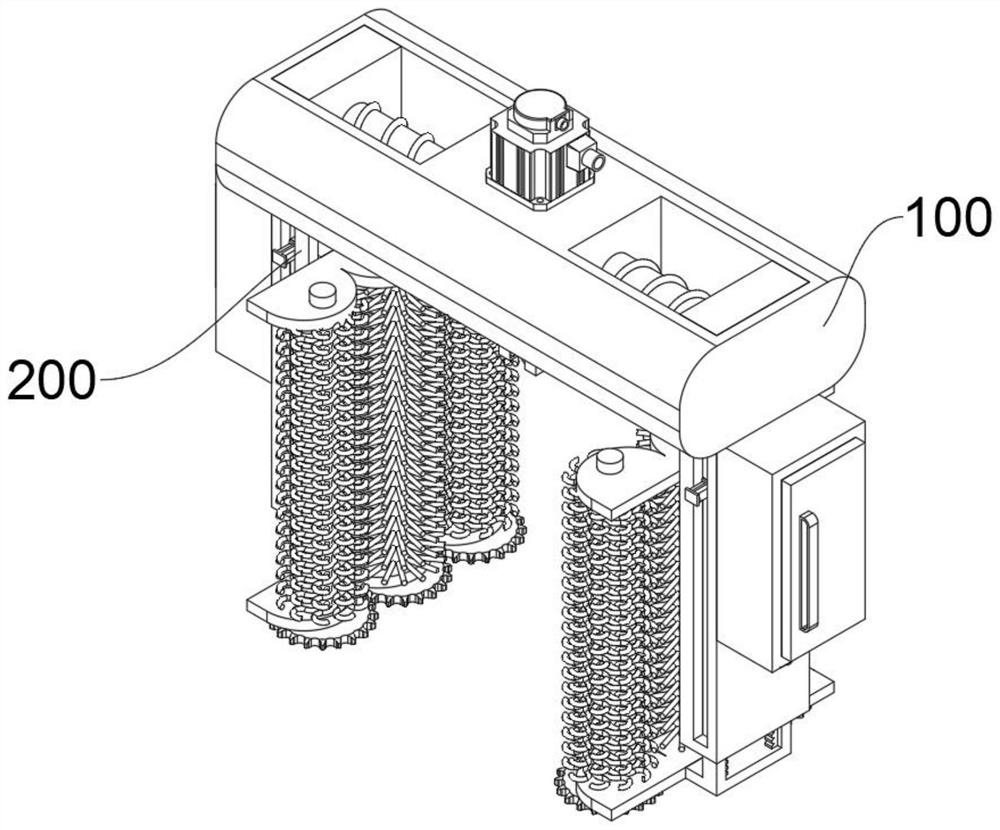

[0047] see Figure 1-Figure 5 As shown, the present embodiment provides a sliding-based cleaning mechanism for aluminum alloy railings, including at least:

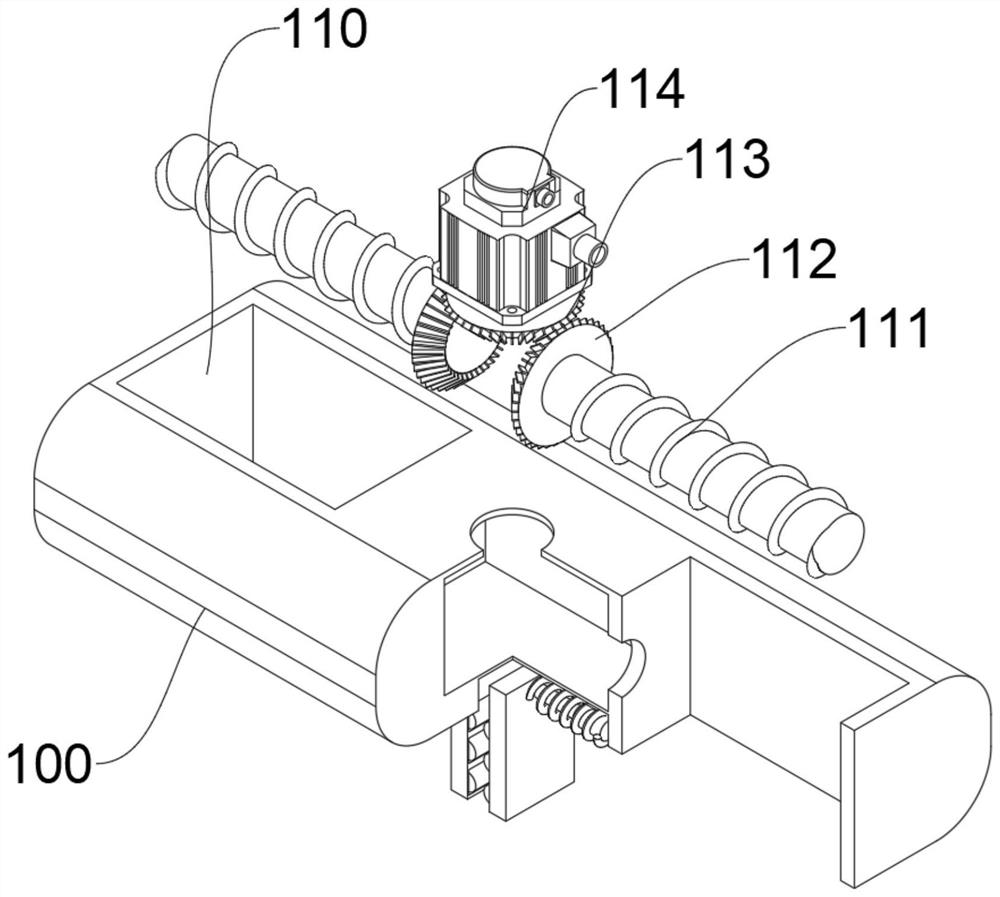

[0048] Fixed frame 100) The top of the fixed frame 100 is provided with two symmetrical adjustment slots 110, and the inside of the adjustment slot 110 is rotated to be provided with a screw rod 111, and the end of the screw rod 111 is fixedly connected with a first bevel gear 112. A second bevel gear 113 is meshed between the outer walls of the gears 112, and the top of the second bevel gear 113 is connected with an output shaft of an adjustment motor 114, and the adjustment motor 114 is fixed on the top of the fixed frame 100. The first bevel gear 112 and the second bevel gear The gears 113 all rotate on the inner layer near the center of the fixed frame 100, and the adjusting motor 114 is powered on to make it work. The output shaft of the adjusting motor 114 drives the second bevel gear 113 to rotate, and the meshing ...

Embodiment 2

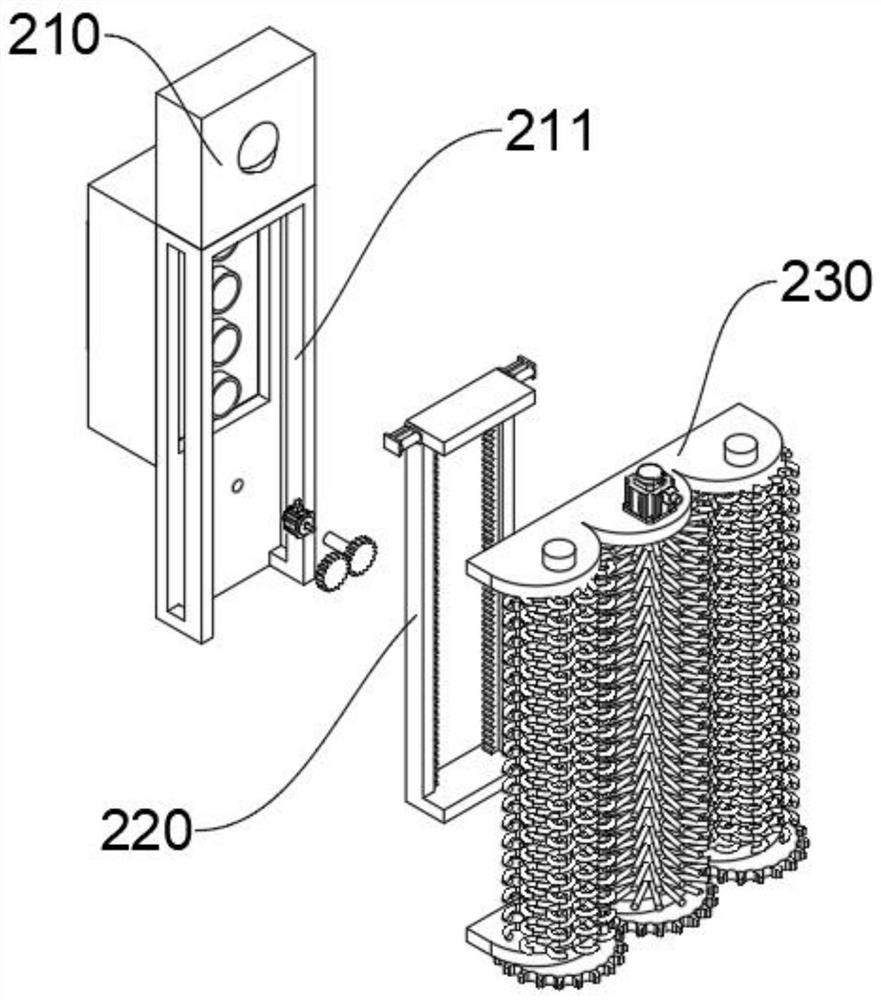

[0054] In order to ensure that the sliding plate 220 slides more stably in the vertical direction and improve the stability of wiping up and down, the difference between this embodiment and Embodiment 1 is that please refer to Figure 6 shown, where:

[0055] Both side walls of the sliding plate 220 near the end are provided with limiting plates 225, and the two side walls of the adjusting plate 210 are provided with a limiting groove 212 communicating with the sliding groove 211. The limiting plate 225 slides inside the limiting groove 212, and can When the sliding plate 220 slides inside the sliding groove 211, the limiting plate 225 arcs inside the limiting groove 212, which can ensure a more stable sliding of the sliding plate 220 in the vertical direction and improve the stability of reciprocating wiping up and down.

[0056] Further, in order to reduce wear and prolong the service life of the limiting plate 225, the surfaces of both sides of the limiting plate 225 are pr...

Embodiment 3

[0058] In order to make the outside dust and water stains can be sucked into the inside of the dust collection box 213 from the end of the dust collection tube 214, so as to avoid dirtying the clothes of the staff, the difference between this embodiment and the first embodiment is that, please refer to Figure 7-Figure 8 shown, where:

[0059] The rear surface of the adjustment plate 210 is connected with a dust collection box 213, and the inner surface of the dust collection box 213 is connected with a plurality of dust suction cylinders 214. The induced draft fan 215 is powered on to make it work, and the motor inside the induced draft fan 215 drives the fan to rotate, so that the dust and water stains from the outside can be sucked into the dust collection box 213 from the end of the dust collection tube 214, thereby avoiding dust and sewage. Fly, to avoid dirty staff clothes, more practical.

[0060] It is worth noting that, in order to facilitate the centralized collecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com