Assembly type shear wall splicing seam waterproof structure

A technology for waterproof structures and joints, which is applied in the direction of walls, building components, building structures, etc., and can solve the problem of reduced contact strength between sealant and joints, and reduced waterproof effect of the outer wall contact between sealant and joints, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

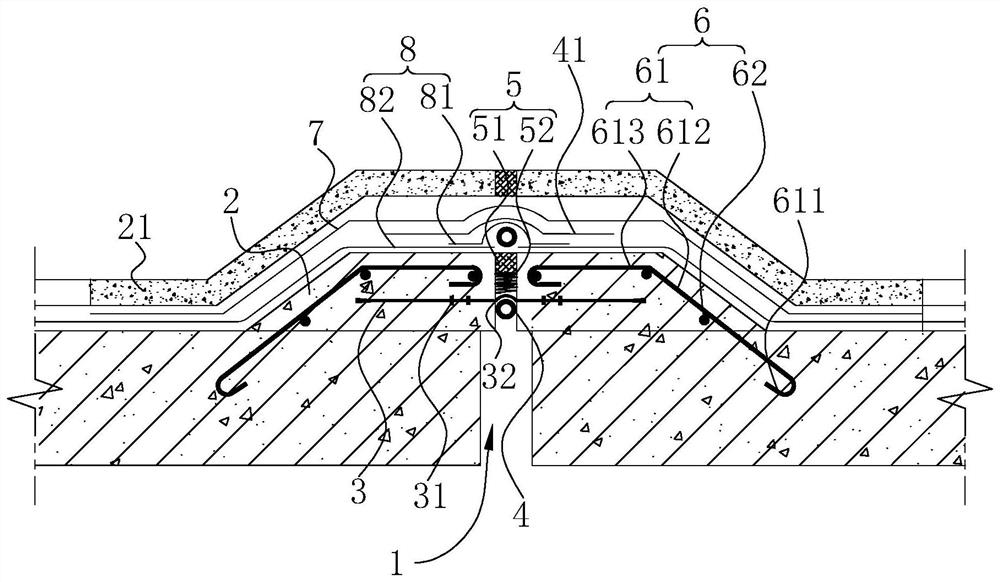

[0035] Refer figure 1 The assembled shear wall splicing seam waterproof structure includes two connection blocks 2 disposed towards the outdoor outer side, and the two connecting block 2 extends in the longitudinal direction of the joint seam 1, and between the two connecting blocks 2 Gap settings. The two connecting blocks 2 are fixedly coupled to both sides of the splicing seam 1, and the opposite sides of the two connecting blocks 2 are in the middle of the edges of the splicing seam 1. Among them, the connecting block 2 is formed to be formed by the concrete or mortar pouring and the splicing seam 1 toward the outdoor opening edge.

[0036] The tapered tape 3 is provided in the splicing seam 1, and the water tape 3 is a rubber stopper tape or a PVC stopper strip. The sides of the stopper strip 3 are respectively fitted within the two connecting blocks 2, and the water strip 3 extends in the extended direction of the joint seam 1. The stopper strip 3 is formed in the edge of th...

Embodiment 2

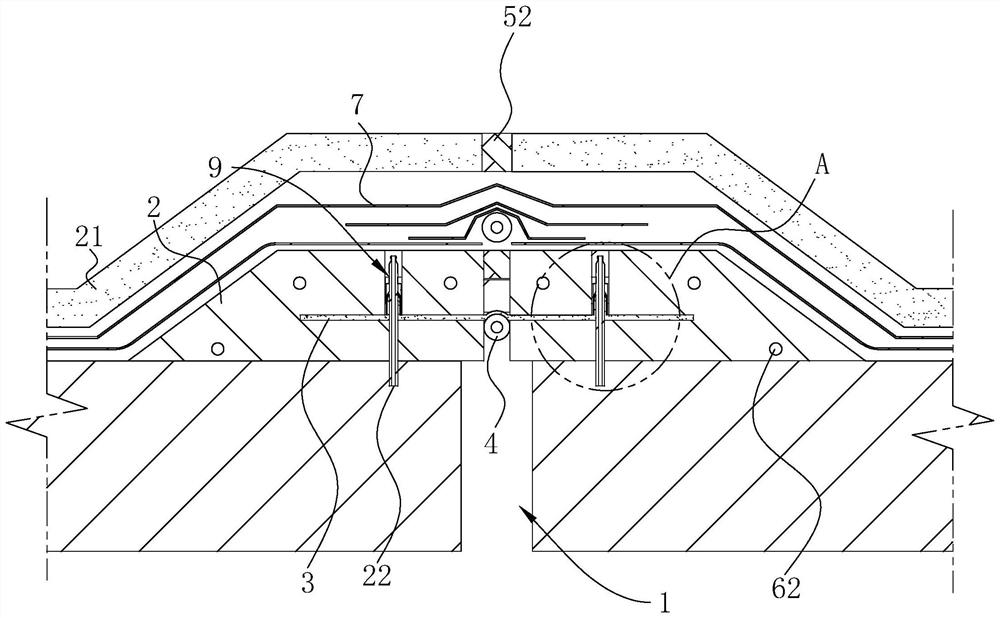

[0052] Refer figure 2 with image 3 The present embodiment differs from the first embodiment in that the connection block 2 is also provided with a grout assembly 9 for further enhancing the contact sealing performance between the connection block 2 and the preform.

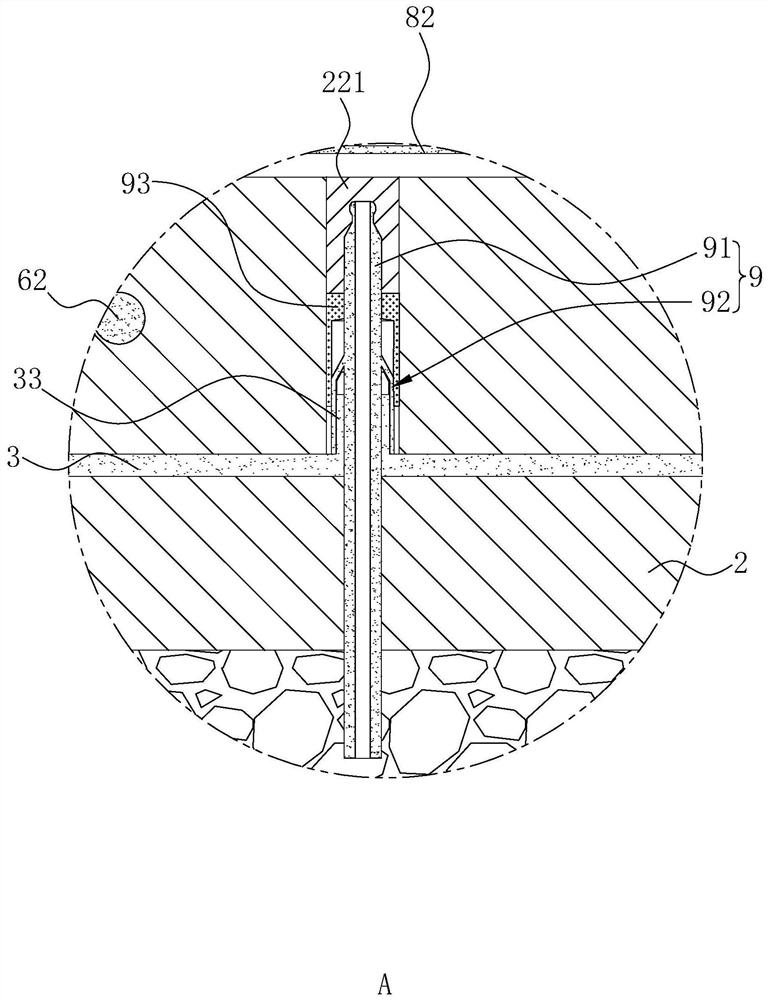

[0053] The connecting block 2 is opened with mounting holes 22 within the prefabricated member, and the water tape 3 is located in the mounting hole 22 protruding into the outdoor side protruding forming a water tube 33. The grout assembly 9 includes a grouting tube 91, and the grouting tube 91 is integrally located in the mounting hole 22, and the grouting tube 91 is inserted into a portion of the prefabricated member toward one end of the chamber, and the grouting tube 91 is placed in a water tube 33.

[0054] The grouting tube 91 is provided with a water supply member 92 for fastening the water tube 33 for sealing.

[0055] Refer image 3 with Figure 4 The soil portion 92 includes a plurality of stopper strips 921 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com