Packing type graded cement injection device

A graded cementing and cementing technology, which is applied in the directions of sealing/isolation, wellbore/well valve device, wellbore/well components, etc., can solve the problem of low pressure bearing capacity and pressure bearing capacity of the annulus of the external isolation of the pipe Problems such as low, rubber tube extrusion deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereby.

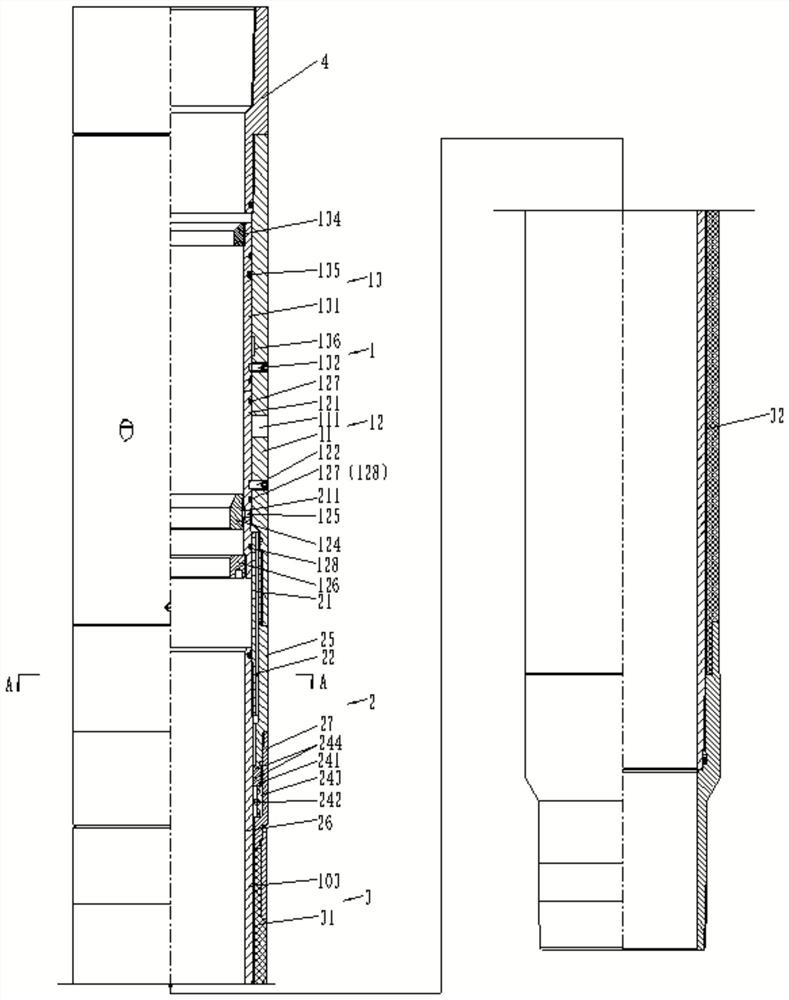

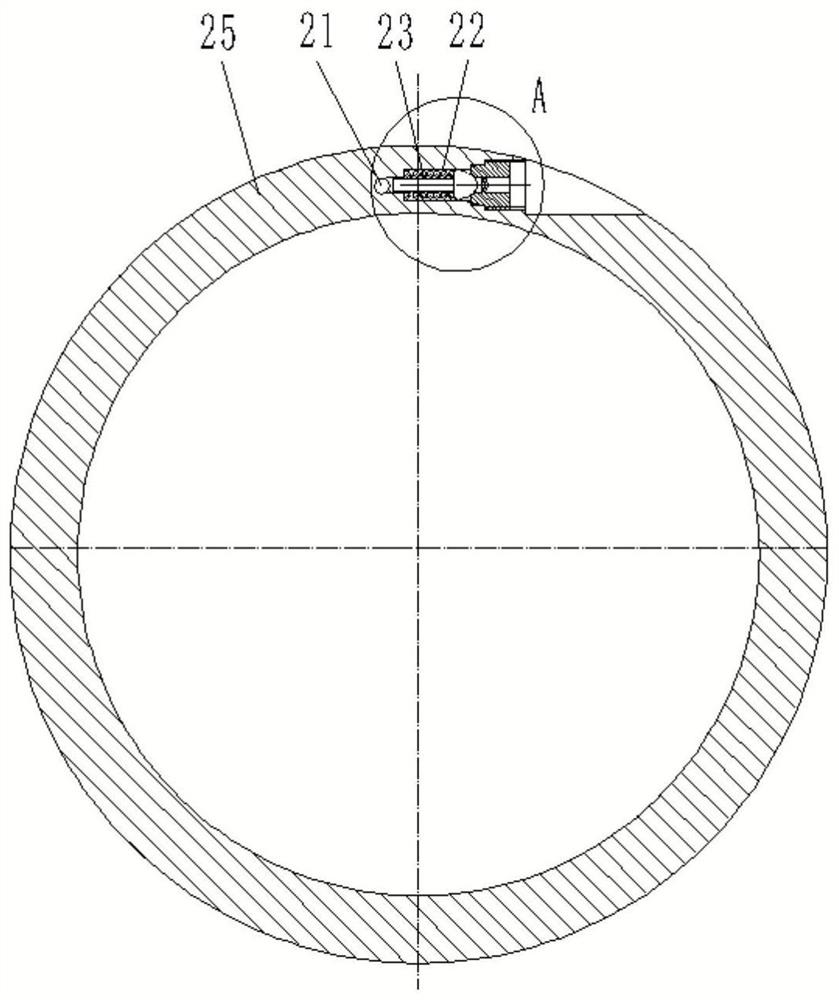

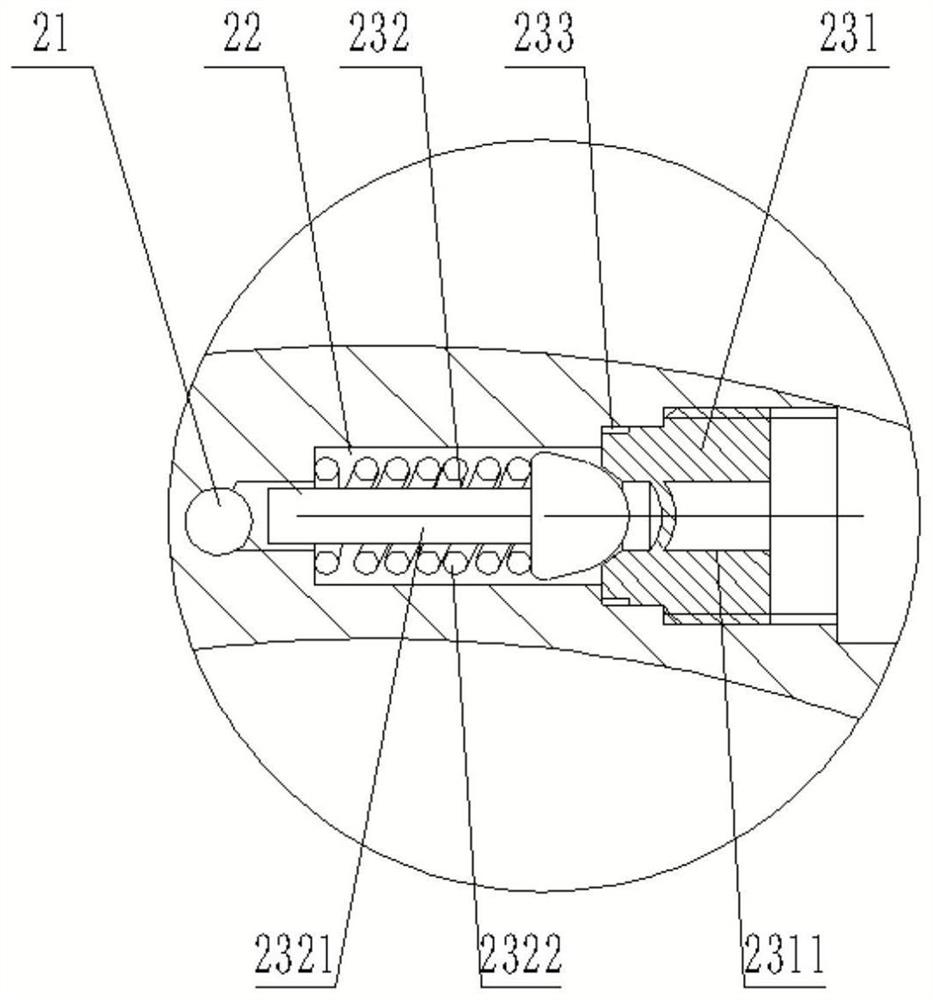

[0032] Such as Figure 1 to Figure 6 An embodiment of the isolated staged cementing device of the present invention is shown, which embodiment is used in the cementing construction of deep wells, ultra-deep wells, and lost wells. In this embodiment, the sealed-type graded cementing device includes a secondary cementing assembly 1, a rubber cylinder liquid injection assembly 2 and a rubber cylinder sealing assembly 3 connected in sequence, and the rubber cylinder liquid injection assembly 2 includes an inner liquid injection channel 21, The outer liquid injection channel 22 and the opening part 23 . Among them, the inner liquid injection channel 21 is arranged along the axial direction of the cementing device, and the two ends of the inner liquid injection chann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com