Exhaust fume collecting hood assembly and range hood

A technology for collecting fume hoods and range hoods, which is applied in the field of kitchen appliances, can solve problems such as easy loosening of filters, achieve a good user experience, and ensure the effect of exhausting smoke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

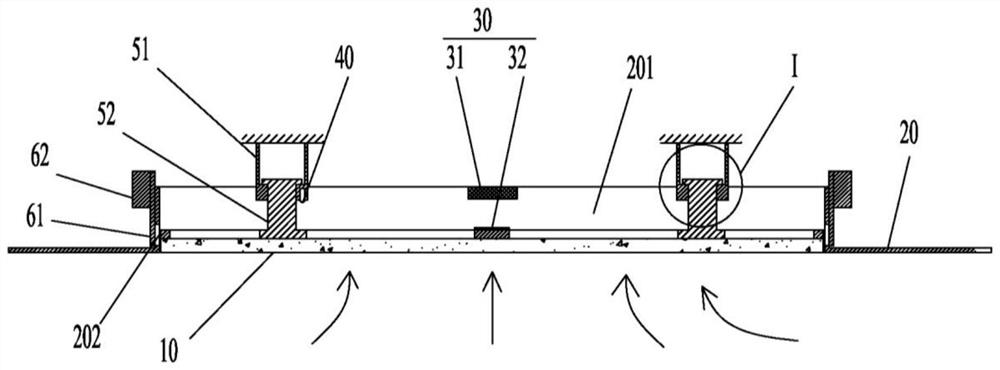

[0048] see Figure 1 to Figure 4 As shown, this embodiment provides a smoke collection hood assembly, including a cover body 20 , a filter screen 10 and a suction assembly 30 ; the filter screen 10 can be fixed in the cover body 20 through the suction assembly 30 .

[0049] In the smoke collecting hood assembly provided in this embodiment, the filter screen 10 is fixed in the cover body 20 by the suction assembly 30, which can prevent the filter screen 10 from loosening.

[0050]Further, the cover body 20 is used to be installed at the air inlet of the air duct system, and the cover body 20 is provided with an air inlet passage 201 communicated with the air outlet of the air duct system; the filter screen 10 is slidably connected in the air inlet passage 201; The net 10 is in a state of sliding balance as the air permeability of the filter net 10 changes.

[0051] When in use, the cover body 20 is installed on the air outlet of the air duct system of the range hood, and when ...

Embodiment 2

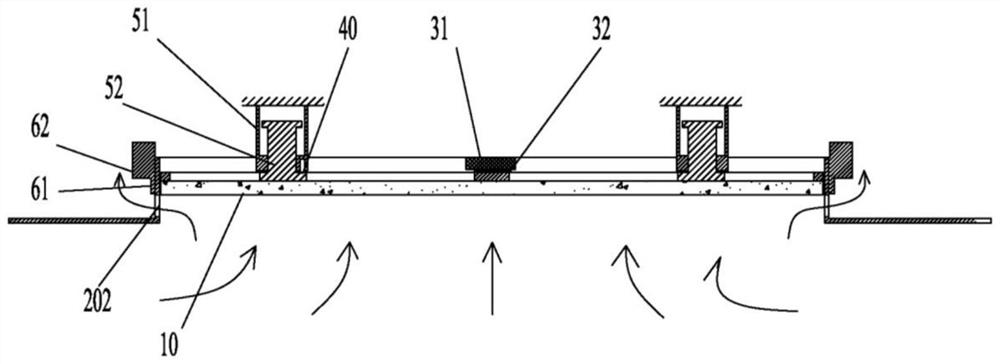

[0082] see Figure 5 with Image 6 As shown, this embodiment also provides a fume collection hood assembly, the fume collection hood assembly of this embodiment is an improvement on the basis of the first embodiment, and the technical solutions of the first embodiment also belong to this implementation For example, the description will not be repeated here. The same components use the same reference numerals as in the first embodiment, and reference is made to the description of the first embodiment.

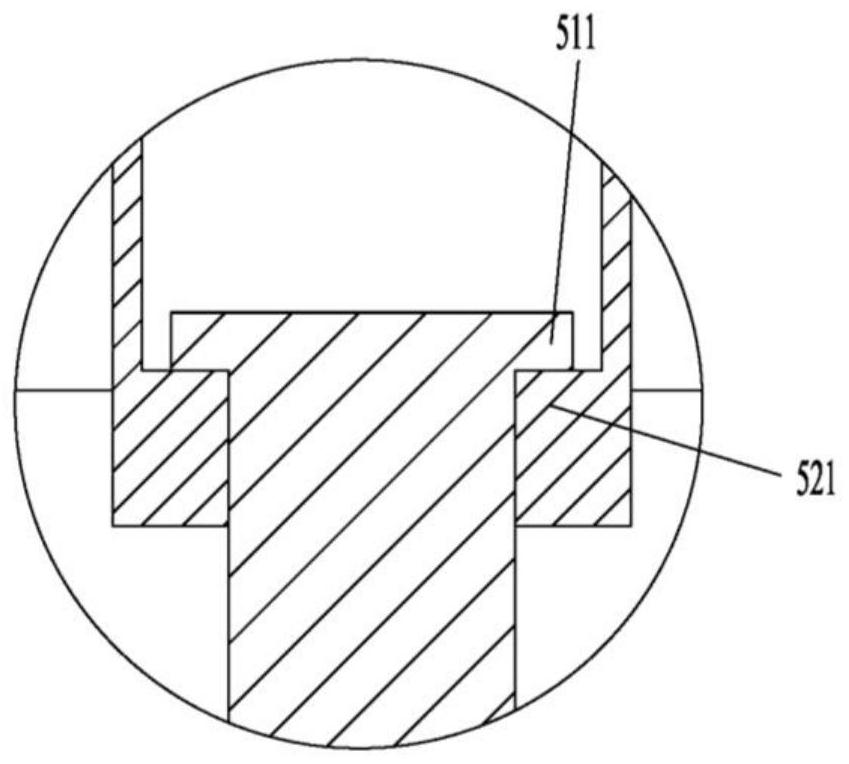

[0083] In this embodiment, the smoke collecting hood assembly further includes an elastic member 53 , and the elastic member 53 is located between the filter screen 10 and the cover body 20 .

[0084] One end of the elastic member 53 is fixedly connected to the guide column 52 , and the other end of the elastic member 53 is fixedly connected to the cover body 20 . The elastic force of the elastic member 53 is designed to be greater than the suction force of the air duct syste...

Embodiment 3

[0087]This embodiment also provides a range hood, including the fume collecting hood assembly provided in Embodiment 1 of the present invention.

[0088] The range hood provided in this embodiment may be a top suction range hood or a side suction range hood.

[0089] Further, the suction assembly 30 and the switch assembly 40 are respectively connected with the main controller of the range hood.

[0090] Further, the main controller of the range hood is set to a constant current working mode to generate a constant air volume, thereby generating a constant negative pressure.

[0091] Further, when the filter screen 10 triggers the switch assembly 40 , the main controller of the range hood sends a message that the filter screen 10 needs to be replaced. For example, the range hood can also be provided with corresponding display lights or alarms, so as to remind customers to replace the filter screen 10 .

[0092] Further, the air duct system of the range hood is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com