A voltage divider insulating cap for DC leakage current test of controllable arrester

A DC leakage and current test technology, which is applied in the field of arrester test, can solve the problems of small insulation distance, inability to withstand high voltage, and inability to withstand high voltage, so as to achieve the effect of increasing insulation strength and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

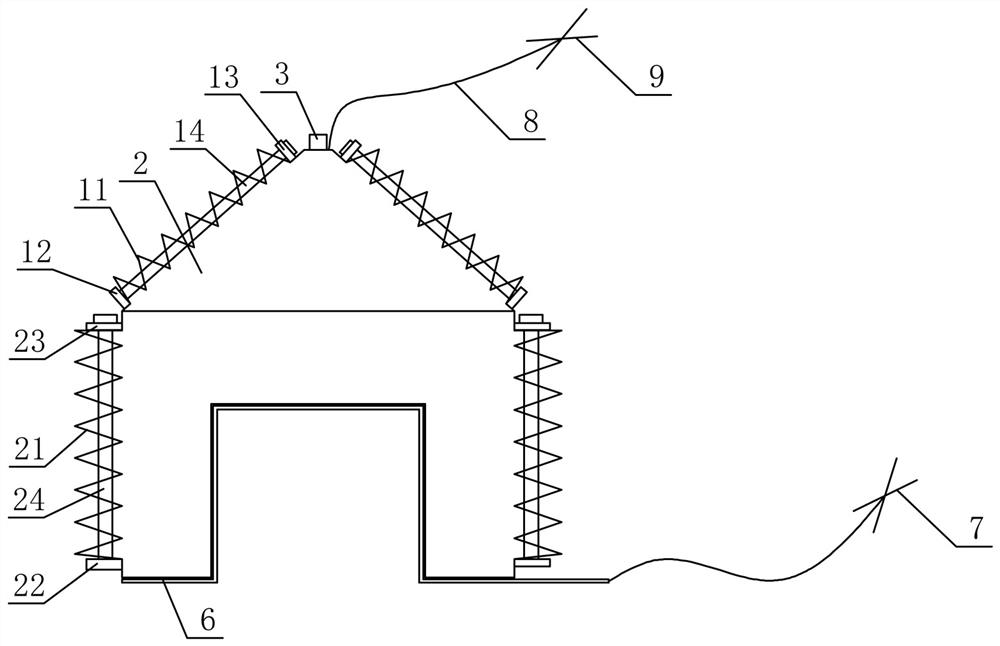

[0075] like figure 1 shown,

[0076] A voltage dividing insulating cap for a DC leakage current test of a controllable arrester, comprising a voltage dividing insulating cap body 10 and an inflatable chamber 2 located in the voltage dividing insulating cap body 10;

[0077] The bottom of the voltage dividing insulating cap body 10 is provided with a groove, and the top thereof is a tower-shaped tip.

[0078] Further, the voltage dividing insulating cap body 10 includes an insulating cap top 11 and an insulating cap side portion 21 fixedly connected below the insulating cap top 11 , and the insulating cap top 11 and the insulating cap side portion 21 are integrally formed with a silicone rubber material. made;

[0079] Further, the outer sides of the insulating cap top 11 and the insulating cap side portions 21 are both folded corrugated surfaces.

[0080] Further, the center of the top surface of the top 11 of the insulating cap is provided with SF for filling 6 Gas inflat...

Embodiment 2

[0083] like figure 1 shown,

[0084] A voltage dividing insulating cap for a DC leakage current test of a controllable arrester, comprising a voltage dividing insulating cap body 10 and an inflatable chamber 2 located in the voltage dividing insulating cap body 10;

[0085] The bottom of the voltage dividing insulating cap body 10 is provided with a groove, and the top thereof is a tower-shaped tip.

[0086] Further, the voltage dividing insulating cap body 10 includes an insulating cap top 11 and an insulating cap side portion 21 fixedly connected below the insulating cap top 11 , and the insulating cap top 11 and the insulating cap side portion 21 are integrally formed with a silicone rubber material. made;

[0087] Further, the outer sides of the insulating cap top 11 and the insulating cap side portions 21 are both folded corrugated surfaces.

[0088] Further, the center of the top surface of the top 11 of the insulating cap is provided with SF for filling 6 Gas inflat...

Embodiment 3

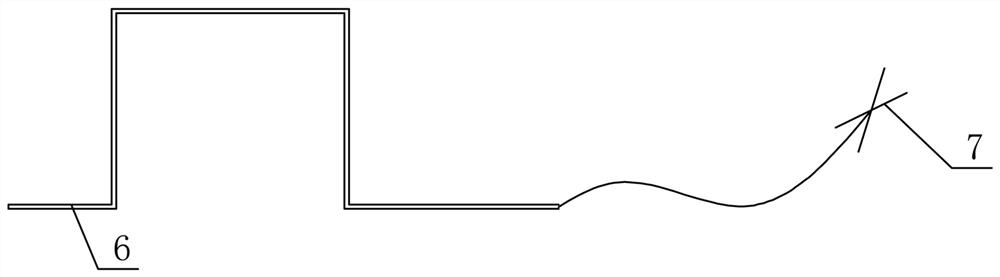

[0096] like figure 1 and 3 shown,

[0097] A voltage dividing insulating cap for a DC leakage current test of a controllable arrester, comprising a voltage dividing insulating cap body 10 and an inflatable chamber 2 located in the voltage dividing insulating cap body 10;

[0098] The bottom of the voltage dividing insulating cap body 10 is provided with a groove, and the top thereof is a tower-shaped tip.

[0099] Further, the voltage dividing insulating cap body 10 includes an insulating cap top 11 and an insulating cap side portion 21 fixedly connected below the insulating cap top 11 , and the insulating cap top 11 and the insulating cap side portion 21 are integrally formed with a silicone rubber material. made;

[0100] Further, the outer sides of the insulating cap top 11 and the insulating cap side portions 21 are both folded corrugated surfaces.

[0101] Further, the center of the top surface of the top 11 of the insulating cap is provided with SF for filling 6 Gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com