Digitization inversion arc welding machine output pole short circuit automatic protection system

An inverter arc welding machine, automatic protection technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve problems such as easy to cause fire, no output pole short circuit automatic protection function, damage to the welding machine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific implementation methods. The schematic implementation and description of the present invention are used to explain the present invention, but are not intended to limit the present invention.

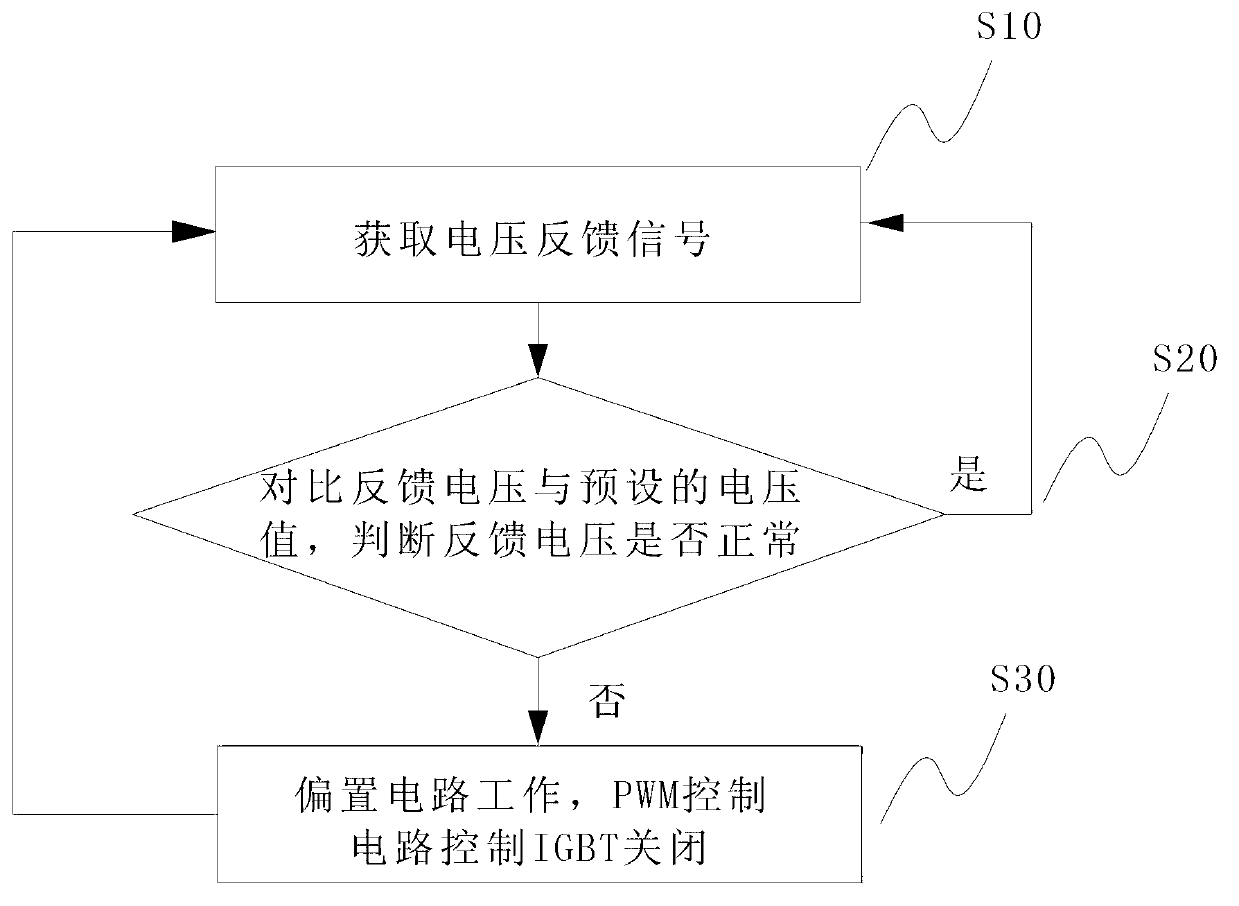

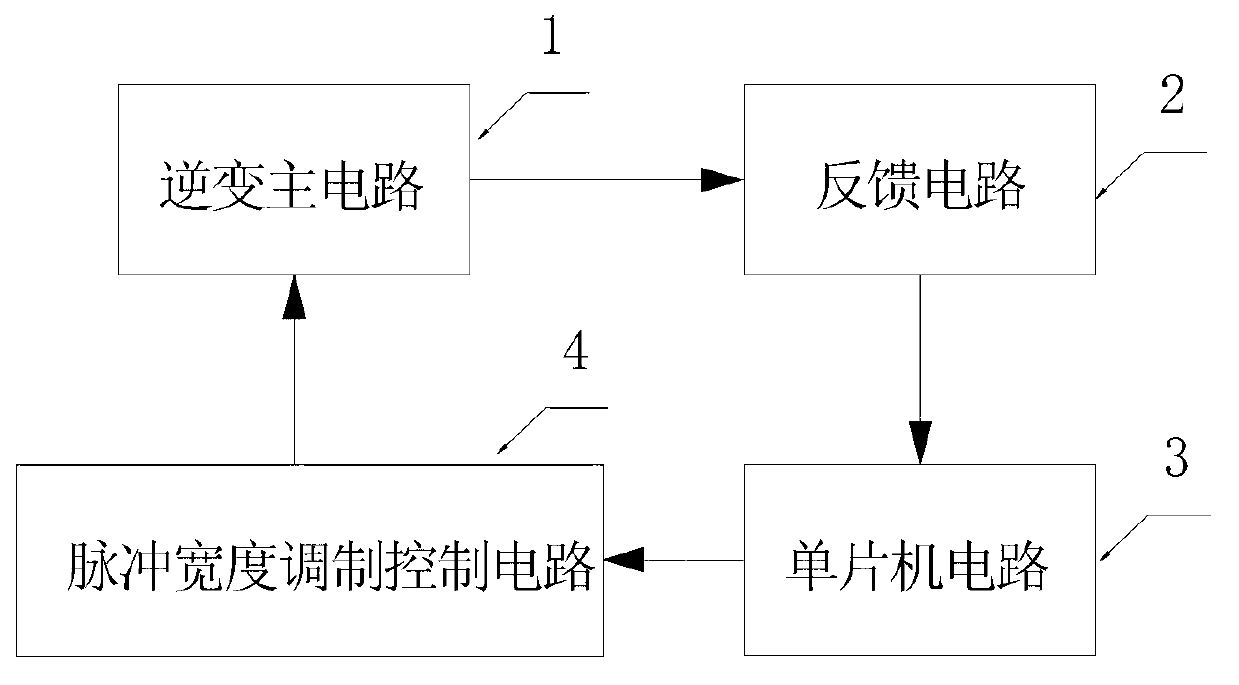

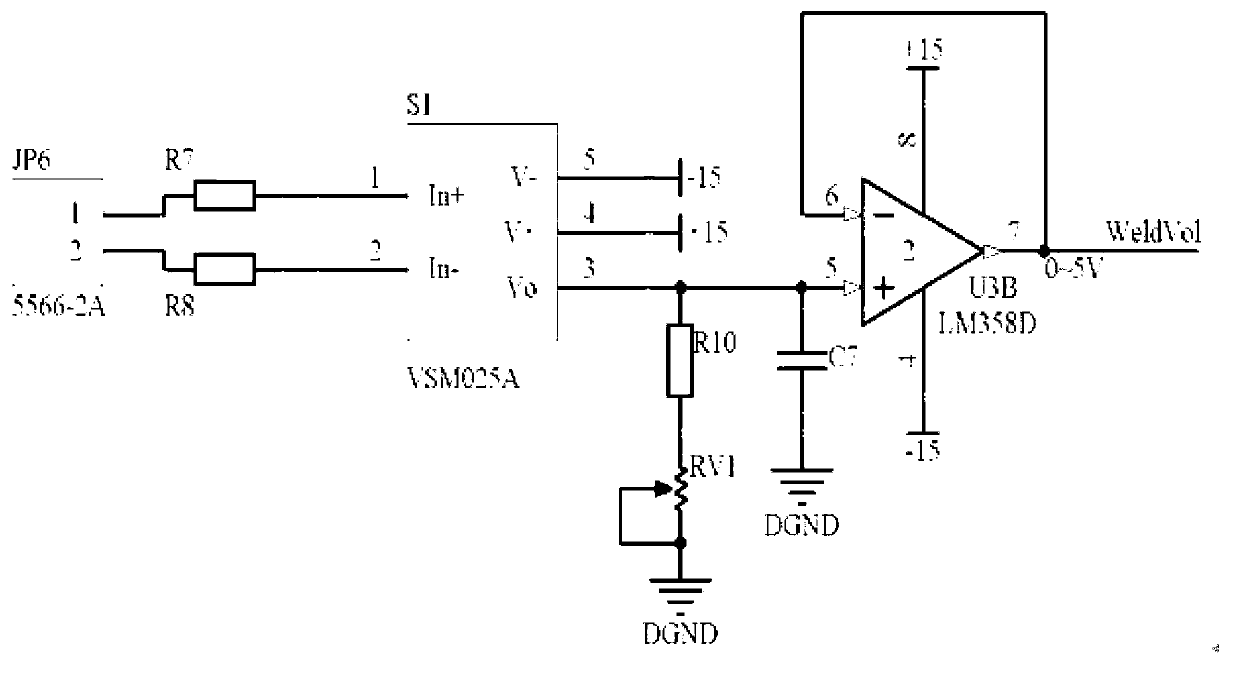

[0026] see figure 1 , which is a flow chart of the automatic protection system for the output pole short circuit of the digital inverter welding machine. It mainly includes the following steps:

[0027] S10: Obtain the feedback voltage.

[0028] S20: Compare the feedback voltage with the preset voltage value to determine whether the feedback voltage is normal, if normal, go to step S10, if not, go to step S30.

[0029] S30: the bias circuit controls the pulse width modulation control circuit to turn off the IGBT.

[0030] In the case of normal operation of the welding machine, the bias circuit controls the pulse width modulation (PWM) control circuit to turn on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com