Special-shaped branch optical cable applied to machine room

A special-shaped and branched technology, which is applied in the field of optical fiber manufacturing, can solve the problems of length restriction of wiring and high cost of wiring construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

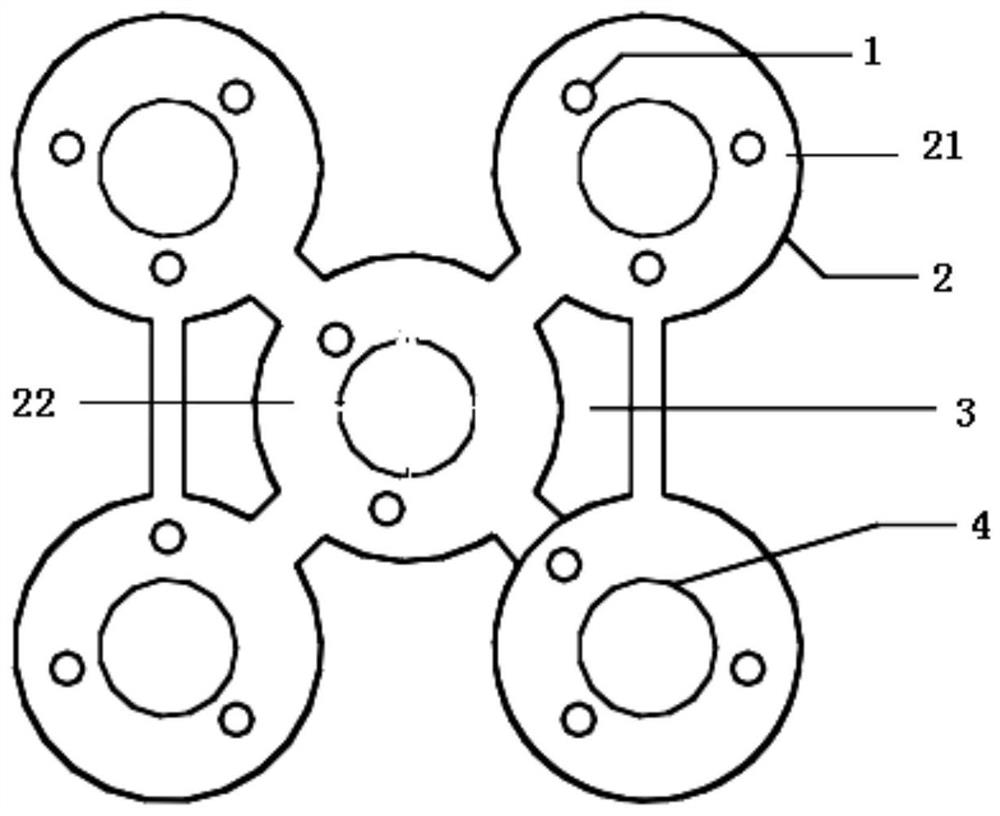

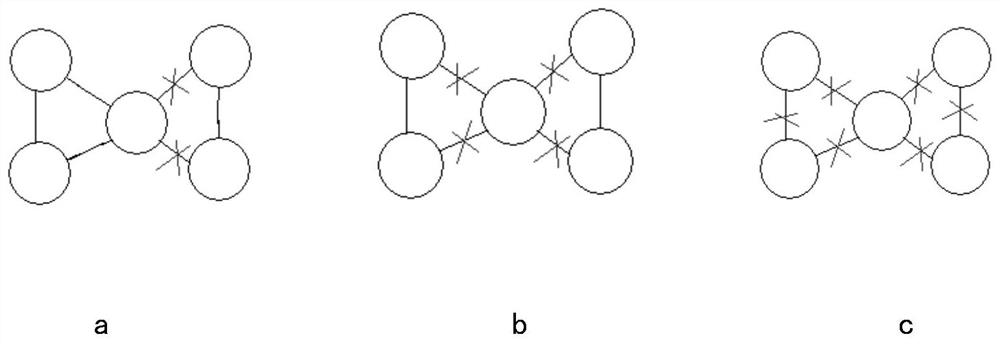

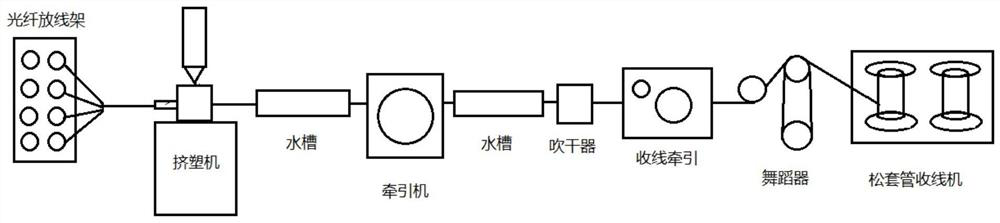

[0026] Such as figure 1 , the special-shaped branch optical cable used in the computer room in this embodiment is mainly composed of: aramid fiber 1, tight sleeve fiber 4 and five outer sheaths 2. The tight sleeve fibers 4 are arranged in the outer sheath 2 correspondingly, and the aramid fibers 1 are evenly wrapped on the outside of the tight sleeve fibers 4 , and three aramid fibers 1 are used in this embodiment. The five outer sheaths 2 consist of a central outer sheath 22 and four peripheral outer sheaths 21 connected to the central outer sheath. Two adjacent peripheral outer sheaths 21 are connected to form a double-core optical cable unit, and a waist-shaped hollow area 3 is formed in each double-core optical cable unit. The special-shaped branch optical cable of this embodiment can be provided with a plug-in connector at the port of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com