Single equipment reliability correction method based on batch equipment reliability evaluation

A reliability and equipment technology, applied in computer-aided design, design optimization/simulation, special data processing applications, etc., can solve problems such as reliability impact, and achieve the best social effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] Embodiment: Select three correction factors of working environment factor, performance test factor and start-up time factor to correct the reliability of a single device;

[0043] (1) Working environment factors

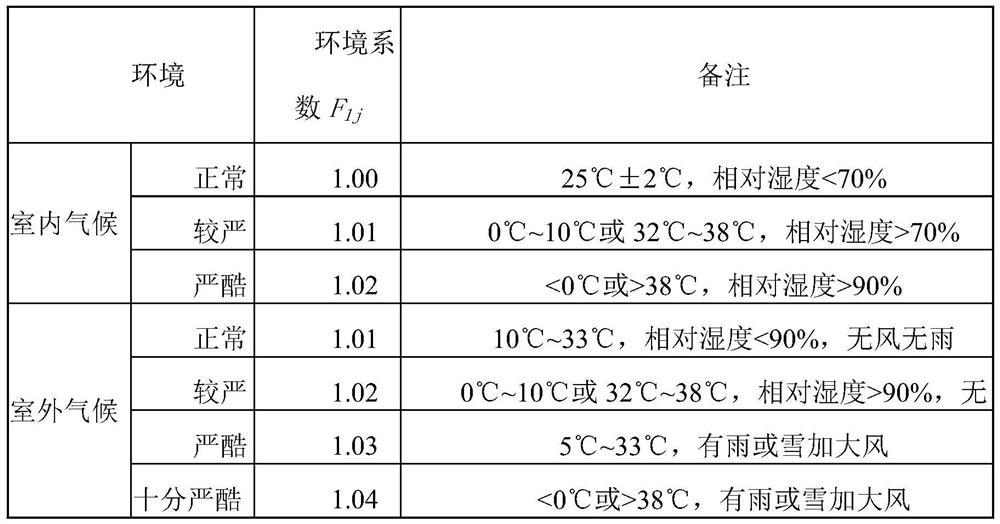

[0044] The working environment factor refers to the degree to which the reliability of the equipment during service is affected by the working time and the environment, which is denoted as F 1 ;Different regions, different working temperature, humidity, etc. have a greater impact on individual equipment; the conversion factors of equipment affected by environmental factors are shown in Table 1;

[0045] Table 1 Value table of environmental factors

[0046]

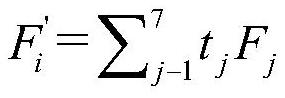

[0047] f 1 The calculation steps are as follows:

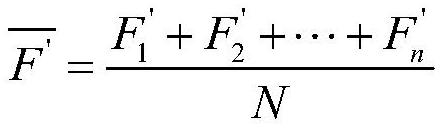

[0048] The first step is to calculate the working time and environmental equivalent value of a single device, F i '; Let a single device experience different time t in different working environments j (j=1,2,…,7), the working time of a single devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com