Functional nutrition fertilizer and preparation method thereof

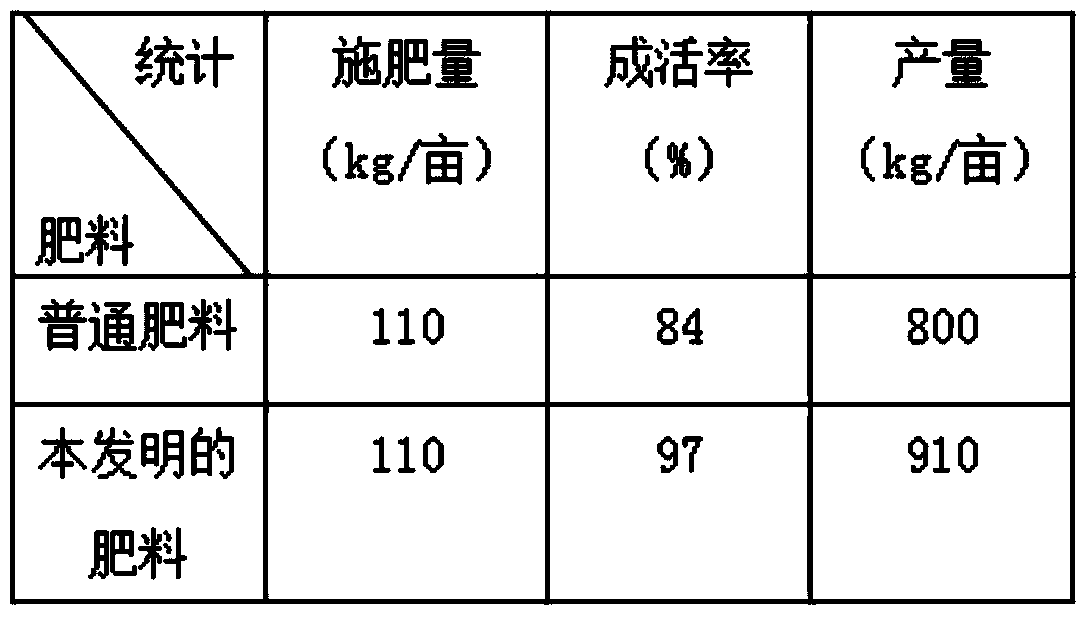

A functional and nutritious technology, applied in the direction of fertilizer mixture, fertilization device, application, etc., can solve the problems of short fertilizer effect period, low fertilizer utilization rate, environmental pollution, etc., achieve good adsorption and expansion, and promote the absorption of nutrients , Improve the effect of yield and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Specific implementation plan

[0016] The present invention will be further described in detail below in conjunction with the following specific embodiments:

[0017] Weigh the following parts by weight (kg) of raw materials: beer lees 53, bean curd residue 32, urea 33, potassium chloride 24, yellow sodium humate 11, calcium carbonate 13, bentonite 5, zeolite powder 4, borax 3, sulfuric acid Ferrous 2, starch 7, EM bacteria agent 4, coating agent 5, appropriate amount of water;

[0018] The coating agent is made of the following parts by weight (kg) of raw materials: chlorinated paraffin 21, dipentaerythritol hexaacrylate 11, silane coupling agent KH-5703, aluminum trichloride 2, aluminum oxide 1, cross Coupling agent TAC1, nano carbon 0.1, medical stone powder 2, zinc gluconate 1; its preparation method is to mix the raw materials, grind and disperse them uniformly.

[0019] The specific steps of the fertilizer preparation method are as follows:

[0020] (1) Mix starch and EM ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com