Rotor for electric machine, electric machine and motor vehicle

A technology for motor vehicles and rotors, applied in electric components, magnetic circuit rotating parts, electromechanical devices, etc., can solve problems such as reducing motor performance and loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

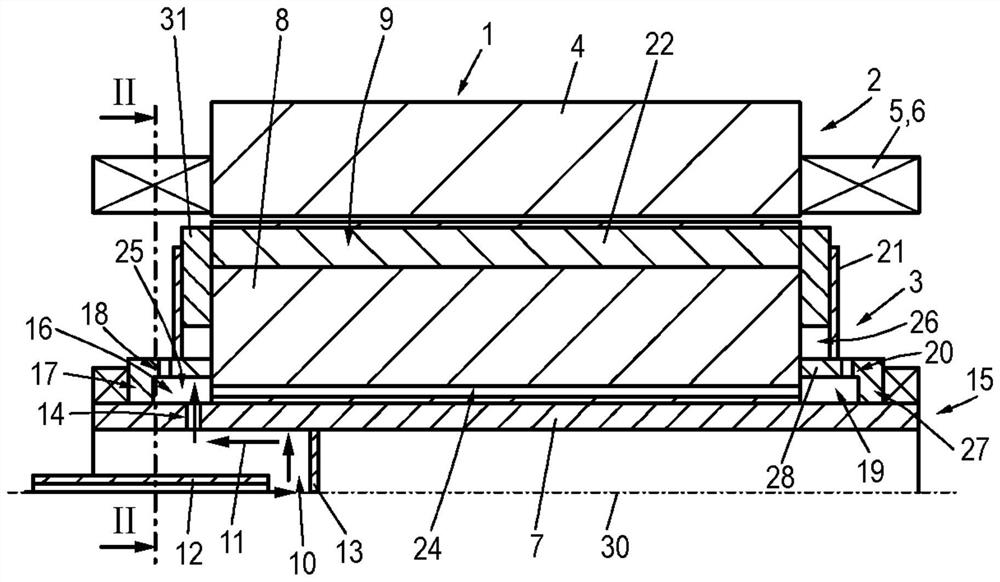

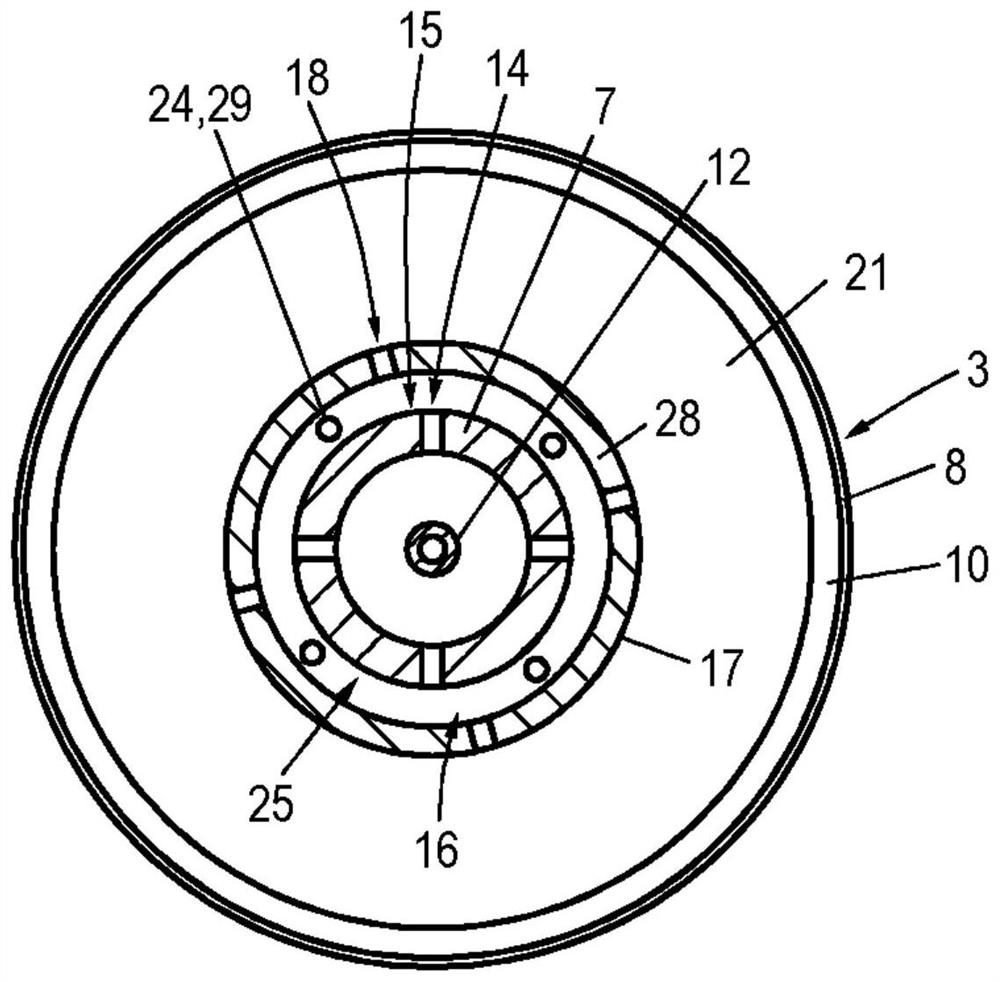

[0027] figure 1 An electric machine 1 is shown, which comprises a stator 2 and a rotor 3 rotatably mounted relative to the stator 2 . exist figure 1 A section of the electric machine 1 is shown in , where only the part of the electric machine 1 on the side of the axis of rotation 30 is shown for reasons of clarity and because of the symmetrical structure of the electric machine 1 . The stator 2 comprises a stator-side carrier 4 - for example a lamination stack - and a winding 5, in figure 1 Only the winding head 6 of the winding is shown in . The stator 2 can be cooled, for example, by means of a water jacket cooling (not shown).

[0028]The rotor 3 comprises a rotor shaft 15 and a carrier 8 , for example a lamination stack, which is coupled to the rotor shaft 15 in a non-rotatable manner, which carries a squirrel-cage winding 9 via conductor bars 22 and short-circuits connecting the conductor bars. Ring 31 is formed. Instead of the squirrel-cage winding 9 , at least one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com