Energy-saving and environment-friendly rapeseed seeding equipment

An energy-saving, environmentally friendly, rapeseed technology, which is applied in sowing, planter parts, hole-seeding planters, etc., can solve the problems of low seeding efficiency and high seeding cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

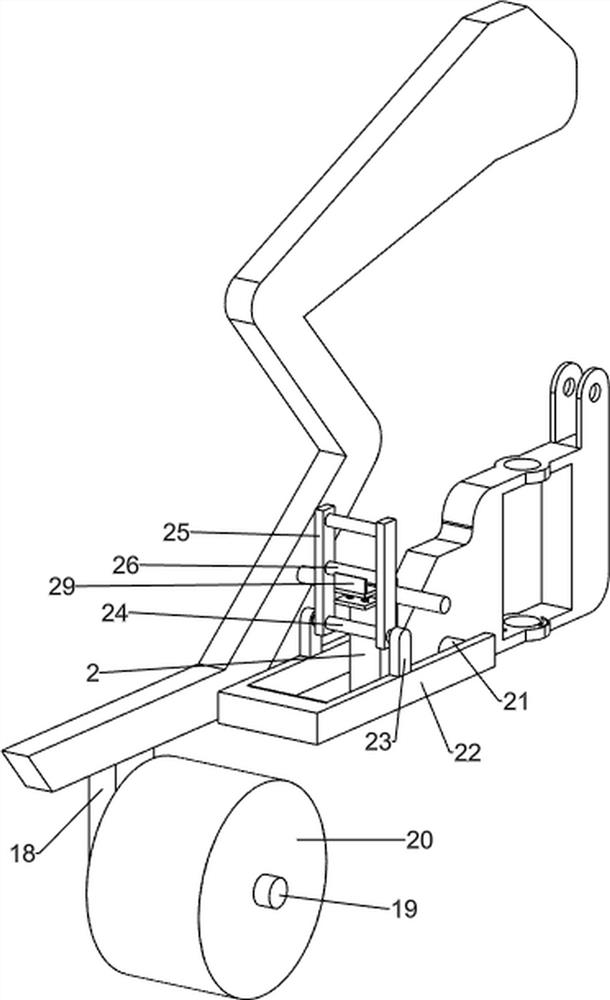

[0030] like figure 1 As shown, an energy-saving and environment-friendly rapeseed sowing equipment includes a wheel 1, a support frame 2, a handle 3, a feeding hopper 4, a driving mechanism 5, a rotating extrusion mechanism 6, a feeding rod 7, a circular plate 8 and a first spring 9. A support frame 2 is provided on the pole between the two wheels 1, a handle 3 is symmetrically provided on the left side of the support frame 2, a drop hopper 4 is provided on the right side of the top of the support frame 2, and the support frame 2 The frame 2 is provided with a drive mechanism 5, the middle part of the support frame 2 is provided with a rotary extrusion mechanism 6, and the middle part of the support frame 2 is slidably provided with a blanking rod 7, which is connected with the drive mechanism 5. A circular plate 8 is arranged on the blanking rod 7 , and a first spring 9 is arranged between the bottom of the circular plate 8 and the supporting frame 2 .

[0031] When it is ne...

Embodiment 2

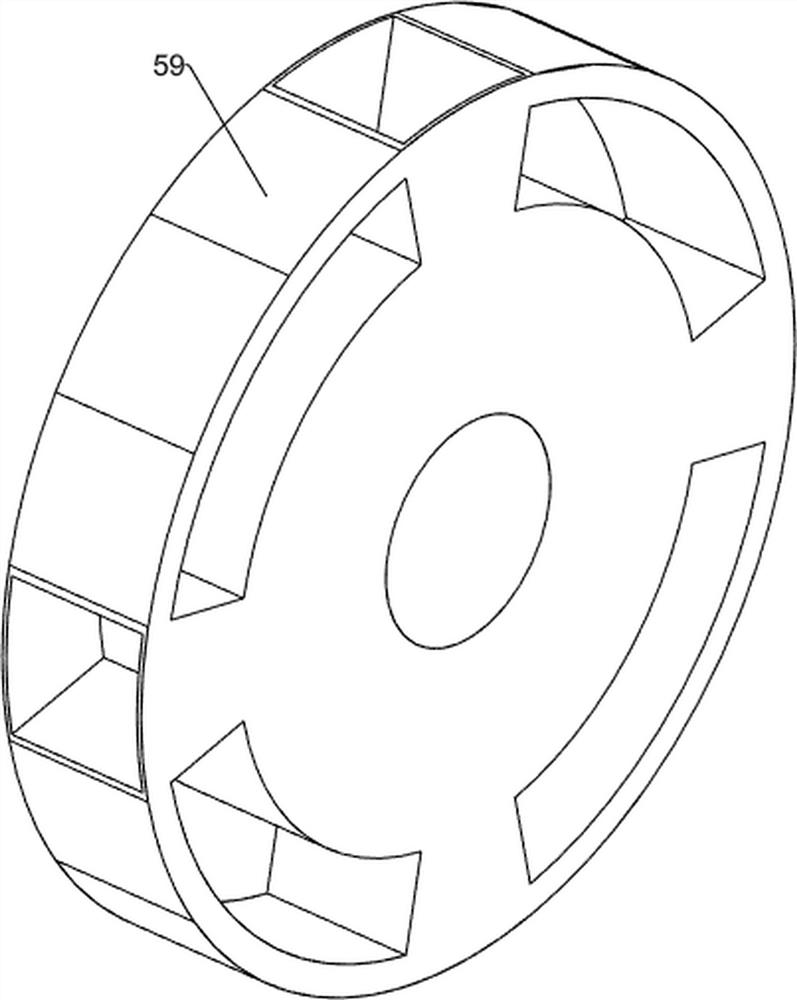

[0033] like figure 2 , image 3 and Figure 4As shown, on the basis of Embodiment 1, the drive mechanism 5 includes a first support plate 51, a servo motor 52, a bearing seat 53, a rotating shaft 54, a first transmission rod 55, a first pulley assembly 56, a second transmission rod 57. The second pulley assembly 58, the blanking tray 59, the support ring 510 and the blanking tube 511, a first support plate 51 is provided between the two handles 3, and a servo motor is provided on the first support plate 51 52, the first support plate 51 is provided with a bearing seat 53, and the bearing seat 53 is rotatably provided with a rotating shaft 54, the output shaft of the servo motor 52 is connected with the rear end of the rotating shaft 54 through a coupling, and the supporting frame 2 The middle rotating type is provided with a first transmission rod 55, and a first pulley assembly 56 is arranged between the front end of the rotating shaft 54 and the front end of the first...

Embodiment 3

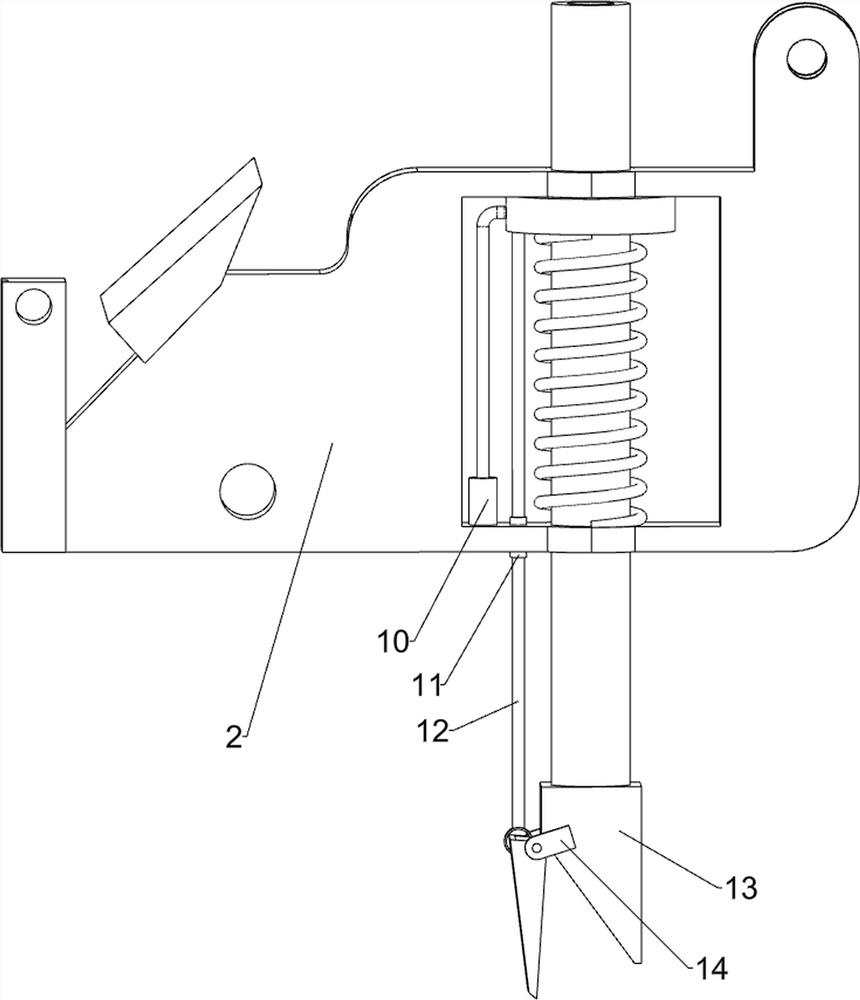

[0038] like Figure 5 , Image 6 , Figure 7 , Figure 8 and Figure 9 As shown, on the basis of Embodiment 2, it also includes a fixed column 10, a limit cylinder 11, a stay cord 12, a hollow pointed iron block 13, a support block 14, a second connecting rod 15, a magnetic cover 16 and an excellent Arc ring 17, the middle part of the support frame 2 is provided with a fixed column 10, the middle part of the support frame 2 is provided with a limit cylinder 11, and the fixed column 10 is provided with a stay rope 12, and the stay rope 12 runs through the circular plate 8 and the limit Barrel 11, the bottom end of the blanking rod 7 is provided with a hollow pointed iron block 13, and the left side of the hollow pointed iron block 13 is provided with a support block 14 symmetrically front and back, and the two support blocks 14 are arranged in a rotating manner There is a second connecting rod 15, and a magnetic cover 16 is arranged on the second connecting rod 15, and a su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com