Detachable feeding and chopping device and harvester thereof

A shredding device and feeding device technology, which is applied in the field of harvesters, can solve the problems of increasing the difficulty of installation and disassembly, the inability to apply clamping force on corn stalks, and increasing the difficulty and cost of maintenance, so as to increase the connection stability, Reduce maintenance difficulty and cost, and facilitate disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Exemplary embodiments of the present disclosure will be described in more detail below with reference to the accompanying drawings. Although exemplary embodiments of the present disclosure are shown in the drawings, it should be understood that the present disclosure may be embodied in various forms and should not be limited to the embodiments set forth herein. Rather, these embodiments are provided so that the present disclosure can be more thoroughly understood and the scope of the present disclosure can be fully conveyed to those skilled in the art.

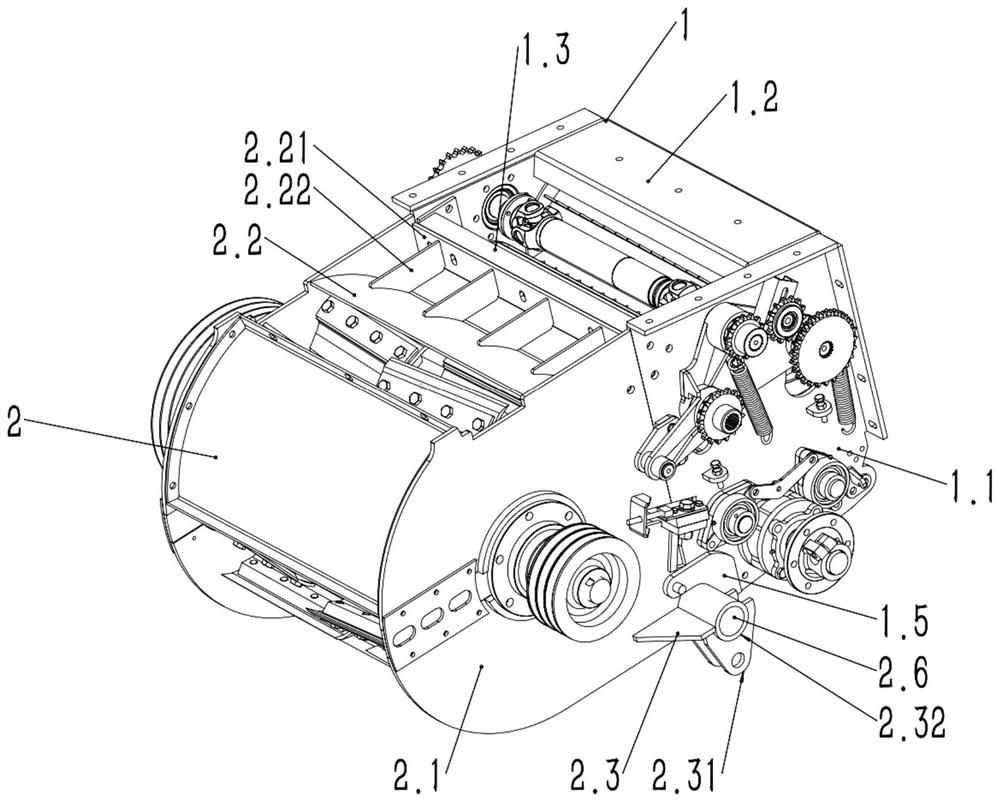

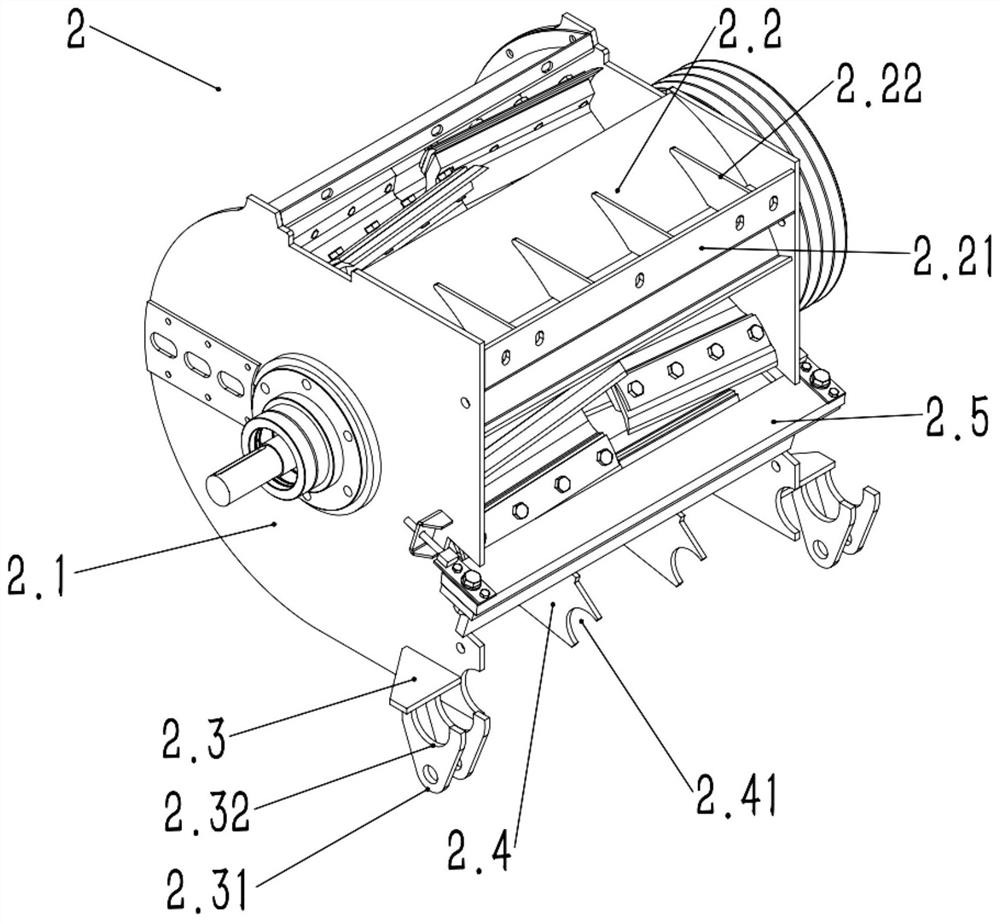

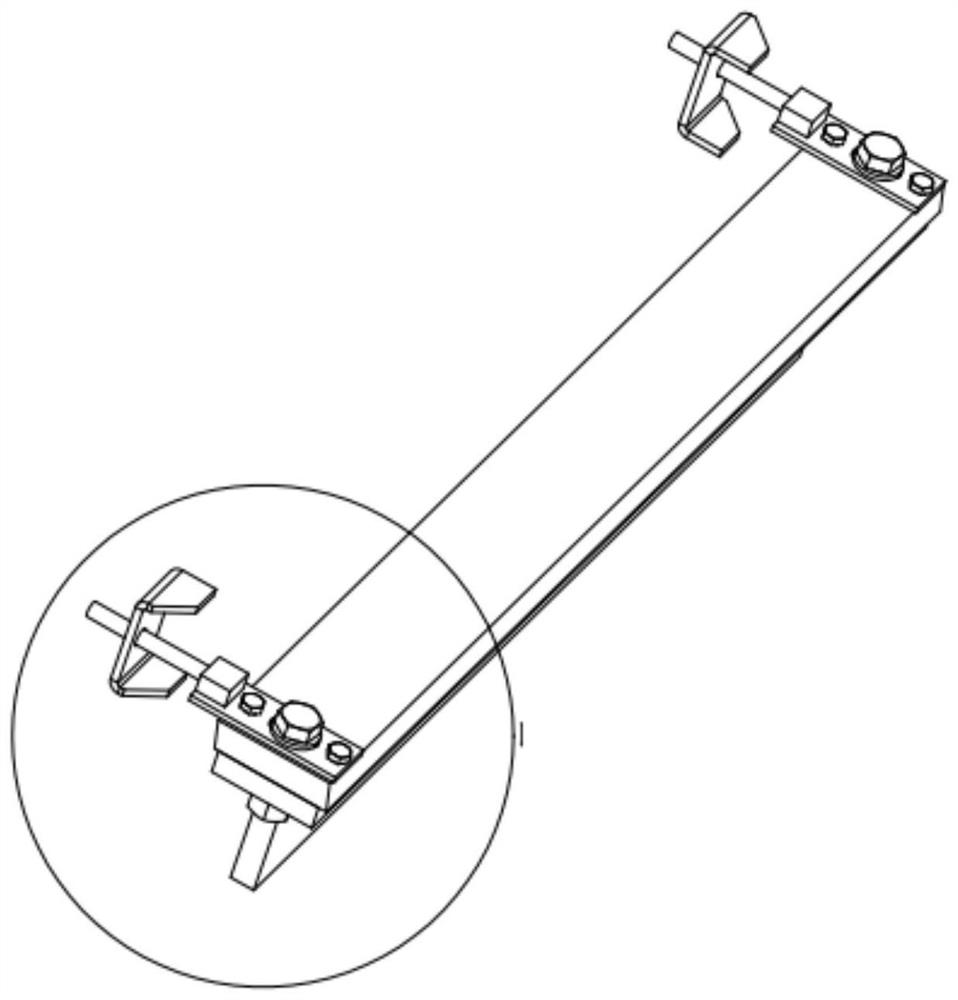

[0036] Such as figure 1 As shown, according to the embodiment of the present invention, a harvester is proposed, including a detachable feeding and chopping device, the feeding and chopping device is installed on the front end of the frame, and the front end of the feeding and chopping device is installed with Straw header.

[0037] Such as figure 1 As shown, the feeding and chopping device includes a feeding device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com