External argon cooling and oil removing system for glove box

A technology of glove box and oil system, which is applied in combination devices, heat exchanger shells, fixed tubular conduit components, etc., can solve the problems of metal lithium pollution and discoloration, metal lithium secondary pollution, etc., and improve oil removal efficiency and cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

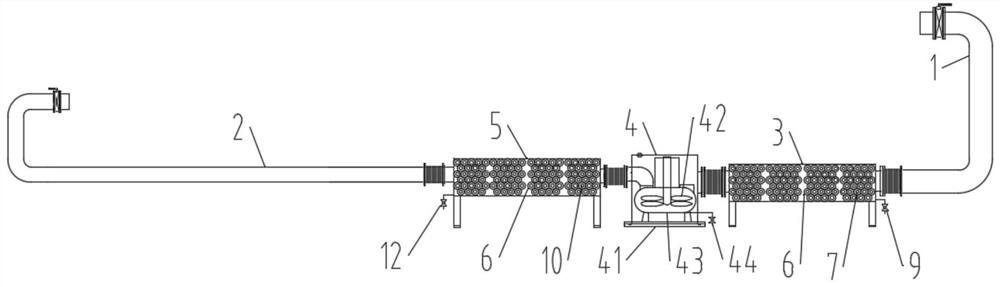

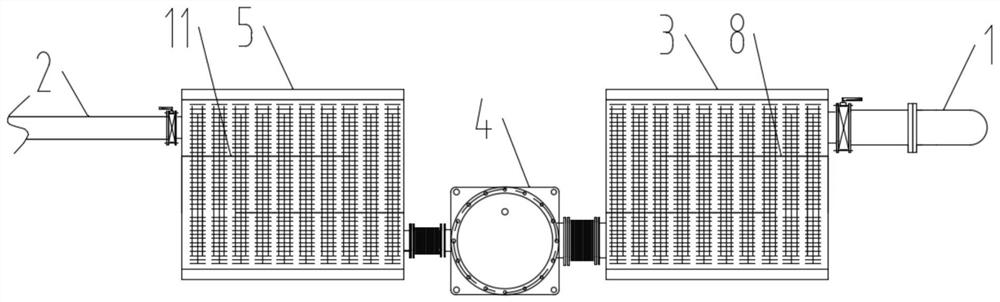

[0033] Such as figure 1 , 2 As shown, the core of the present invention is to provide a glove box argon external cooling and degreasing system, which includes a glove box for casting lithium ingots under an argon atmosphere, and also includes first tubes 1 respectively arranged at both ends of the glove box and the second pipe 2, one end of the first pipe 1 and the second pipe 2 are in communication with the glove box, and the other end of the first pipe 1 and the other end of the second pipe 2 are sequentially connected with a first cooler 3, a rotary The flow degreaser 4 and the second cooler 5, the inlet end of the swirl degreaser 4 is connected with the outlet end of the first cooler 3, the outlet end of the swirl degreaser 4 is connected with the inlet end of the second cooler 5 connected, the first cooler 3 and the second cooler 5 are filled with oil removal filter elements 6 .

[0034] It should be noted that the glove box is provided with an air outlet and an air inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com