Cylinder body milling surface machining auxiliary tool

A technology of auxiliary tooling and milling surface, applied in the field of workpiece processing, which can solve the problems of unstable flatness, easy loosening, and vibration lines on the flange surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

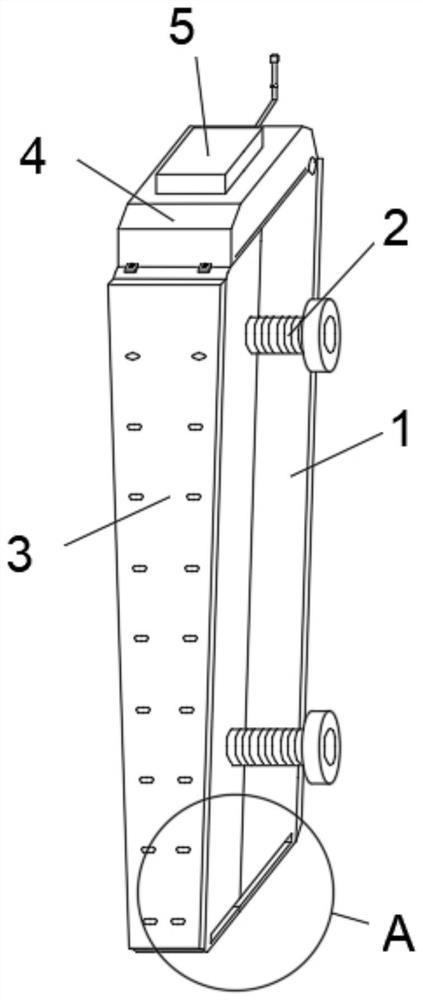

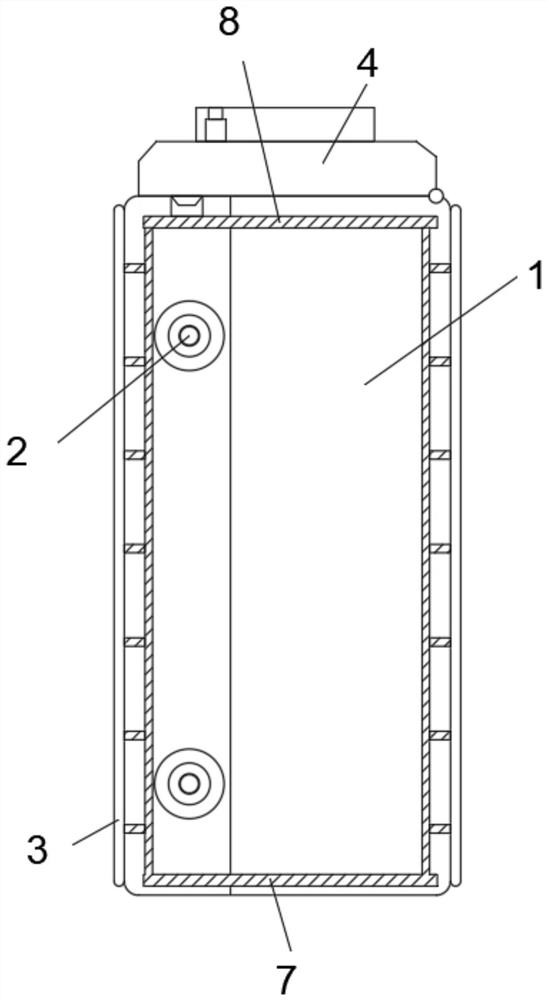

[0024] The following is attached figure 1 , to further illustrate the specific implementation of the cylinder face milling auxiliary tooling of the present invention. The cylinder face milling auxiliary tooling of the present invention is not limited to the description of the following embodiments.

[0025] This embodiment provides a specific structure of auxiliary tooling for cylinder face milling, such as Figure 1-3 As shown, a cylinder face milling auxiliary tooling, including:

[0026] The auxiliary inclined block 1 is provided with at least two groups of screws 2 on one side thereof for connecting the auxiliary inclined block 1 and the processing table, and the auxiliary inclined block 1 is provided with an inner groove body 8;

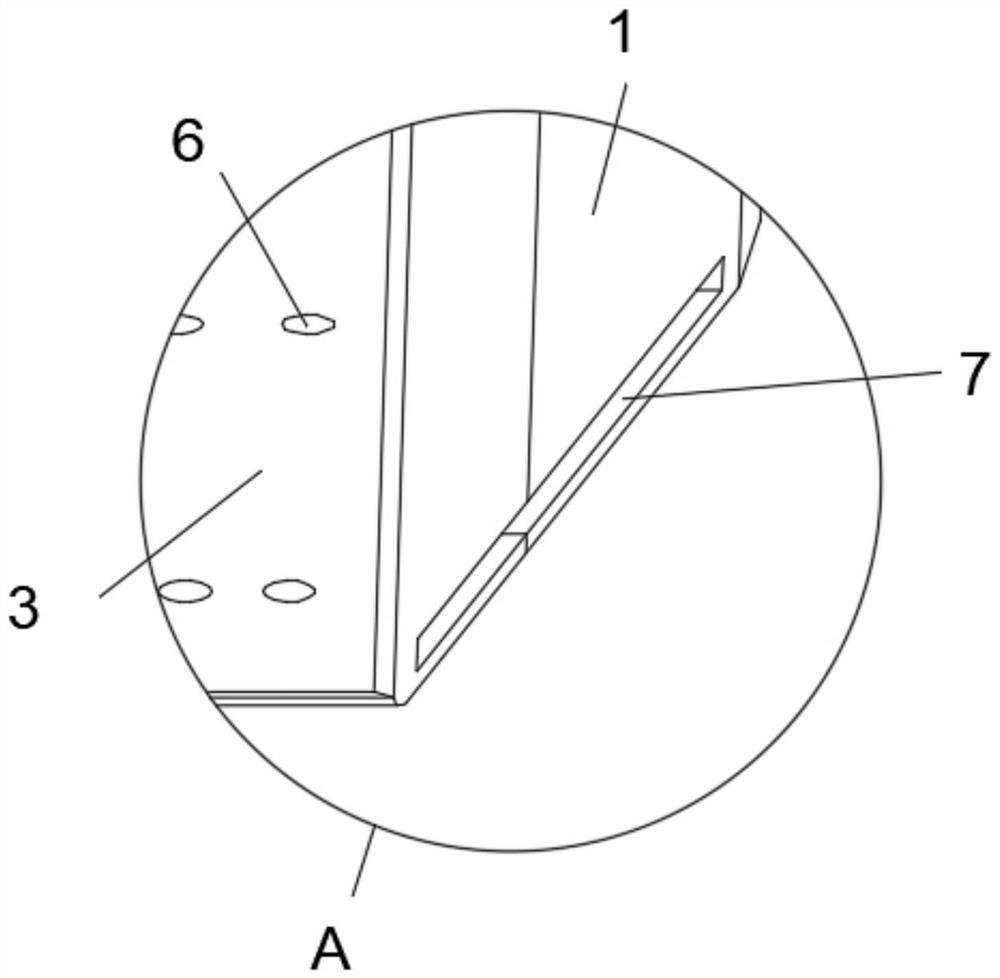

[0027] The rubber pad 3 is bonded to the inclined surface of the auxiliary inclined block 1, and the inclined surface is attached to the processing surface. The surface of the rubber pad 3 is provided with a plurality of pad holes 6, and each ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com