Non-ruler bag automatic identification coil unloading interlocking device

An automatic identification, non-ruler technology, applied in the field of steel rolling, can solve problems such as quality objections, wrong sign information, unattended, etc., to achieve the effect of reducing manual shuttles, realizing automatic control, and ensuring the safety of employees' operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

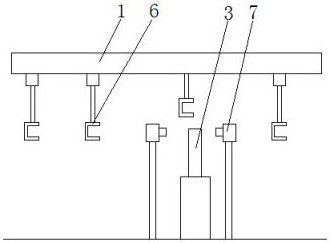

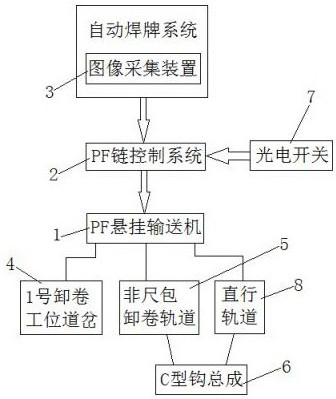

[0013] like figure 1 and figure 2 The shown non-foot bag automatic identification and unloading interlocking device includes an automatic welding system and a PF suspension conveyor 1; the PF suspension conveyor 1 is provided with at least one group of switches on its conveying track; the automatic welding system passes The PF chain control system 2 communicates with the PF suspension conveyor 1; the automatic welding plate system is configured with an image acquisition device 3 for identifying non-foot bags; the image acquisition device 3 is installed in the unloading sorting of the PF suspension conveyor place; the unloading and sorting place of the PF suspension conveyor is provided with the No. 1 unloading station switch 4 for guiding the C-shaped hook assembly with the non-foot bag from the straight track to the non-foot bag unloading track; The image acquisition device 3 is communicated with the driving device of the No. 1 unloading station switch 4 through the PF chai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com