Process for treating alkaline wastewater generated in production of polynitrotoluene and device thereof

A treatment process, nitrotoluene technology, applied in water/sewage treatment, water treatment parameter control, heating water/sewage treatment, etc., can solve the problems of inability to re-use, inconsistent indicators, high production costs, and reduce production and operation. cost, improve security, and ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

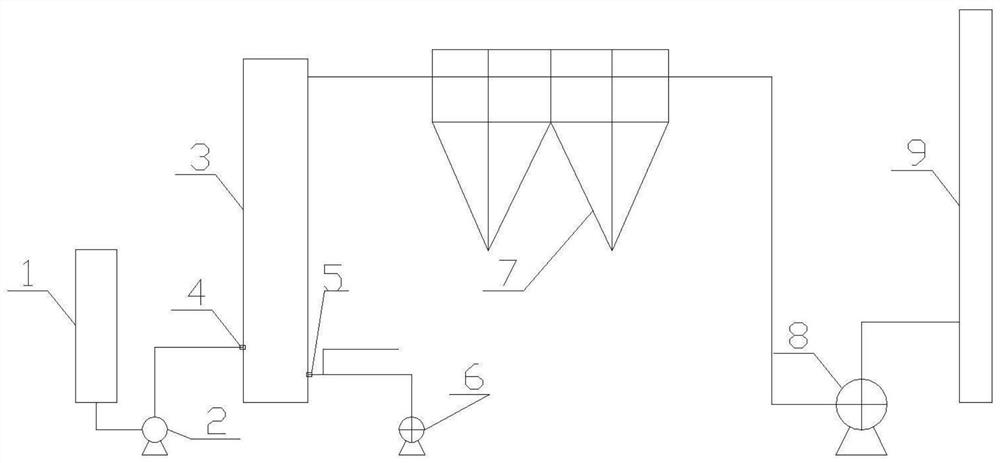

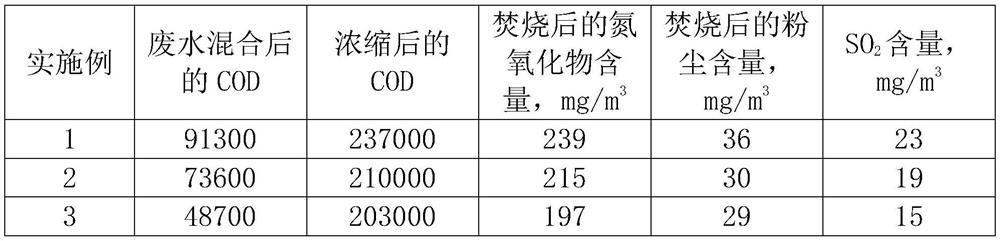

[0052] The polynitrotoluene wastewater is fed according to the volume ratio of mononitrotoluene and trinitrotoluene at 1:4, the concentration conditions are vacuum degree -65kPa, evaporation at 85°C, and the concentrated wastewater feed rate is 600kg / h. The volume flow rate is 250m 3 / h, control the oxygen flow rate to ensure that the combustion coefficient is 0.78, enter the incinerator 3 and burn at 950-1150°C, and then go through the electrostatic precipitator 7 to remove dust.

Embodiment 2

[0054] The polynitrotoluene wastewater is fed according to the volume ratio of mononitrotoluene and trinitrotoluene at 1:1, the concentration conditions are vacuum degree -73kPa, evaporation at 75°C, and the concentrated wastewater feed rate is 1000kg / h. The volume flow rate is 315m 3 / h, control the oxygen flow rate to ensure that the combustion coefficient is 0.8, enter the incinerator 3 and burn at 950-1150°C, and then go through the electrostatic precipitator 7 to remove dust.

Embodiment 3

[0056] The polynitrotoluene wastewater is fed according to the volume ratio of mononitrotoluene and trinitrotoluene at 4:1, the concentration conditions are vacuum degree -95kPa, evaporation at 40°C, and the concentrated wastewater feed rate is 1500kg / h. The volume flow rate is 350m 3 / h, control the oxygen flow rate to ensure that the combustion coefficient is 0.85, enter the incinerator 3 and burn at 950-1150 ° C, and then go through the electrostatic precipitator 7 to remove dust.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap