Fabricated building construction positioning and mounting structure

A technology for building construction and positioning installation, which is applied in the direction of building construction, construction, and building material processing, etc. Rib deflection and other problems can be achieved to save time, manpower and space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

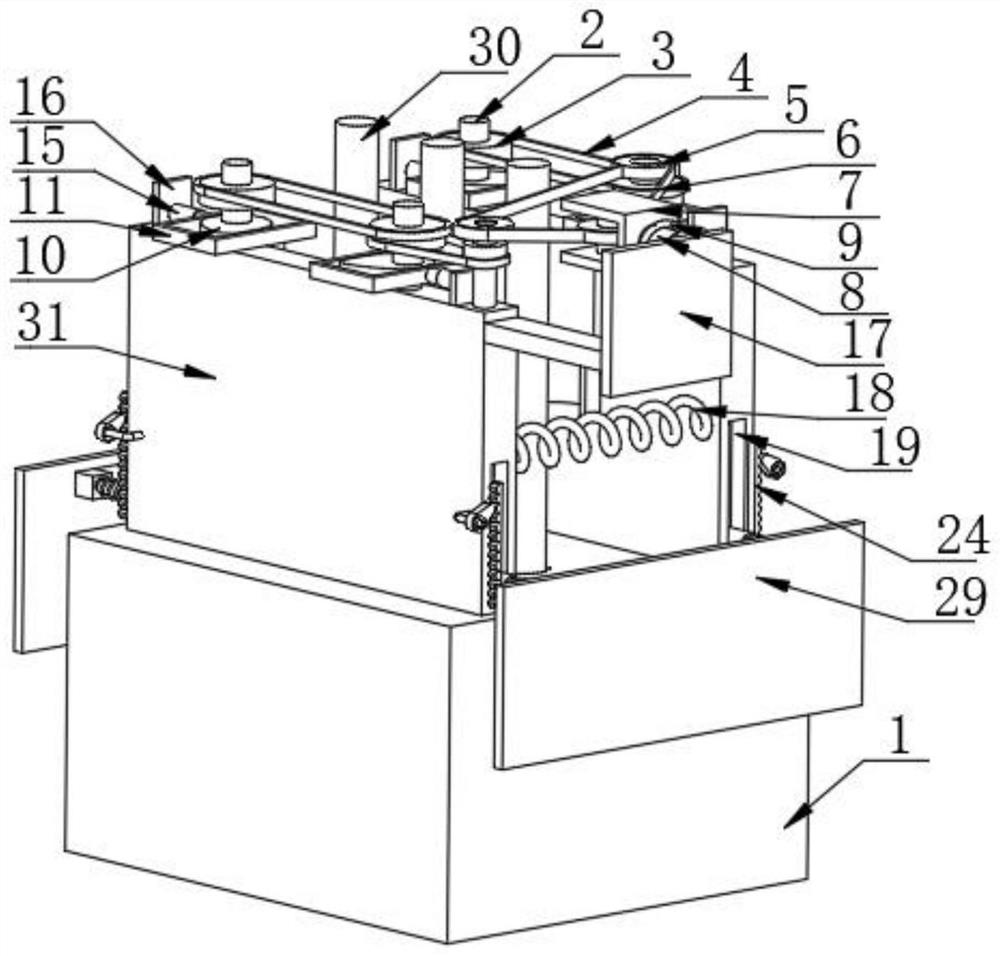

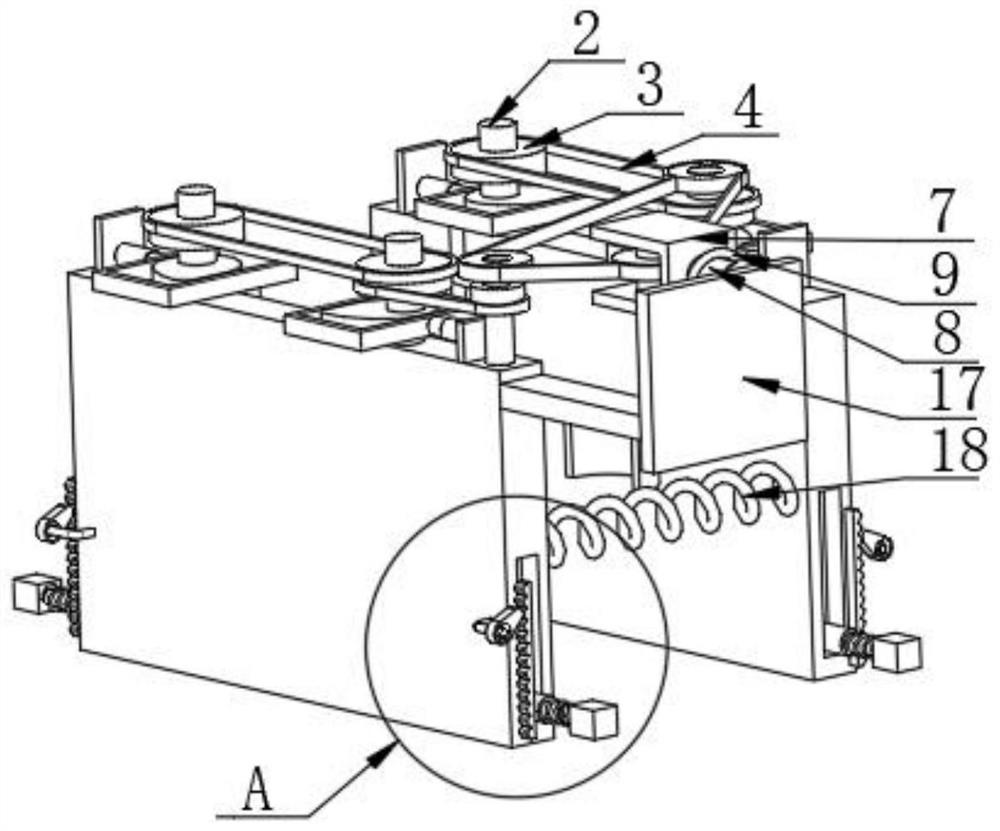

[0031] An embodiment of the present invention provides a prefabricated building construction positioning installation structure.

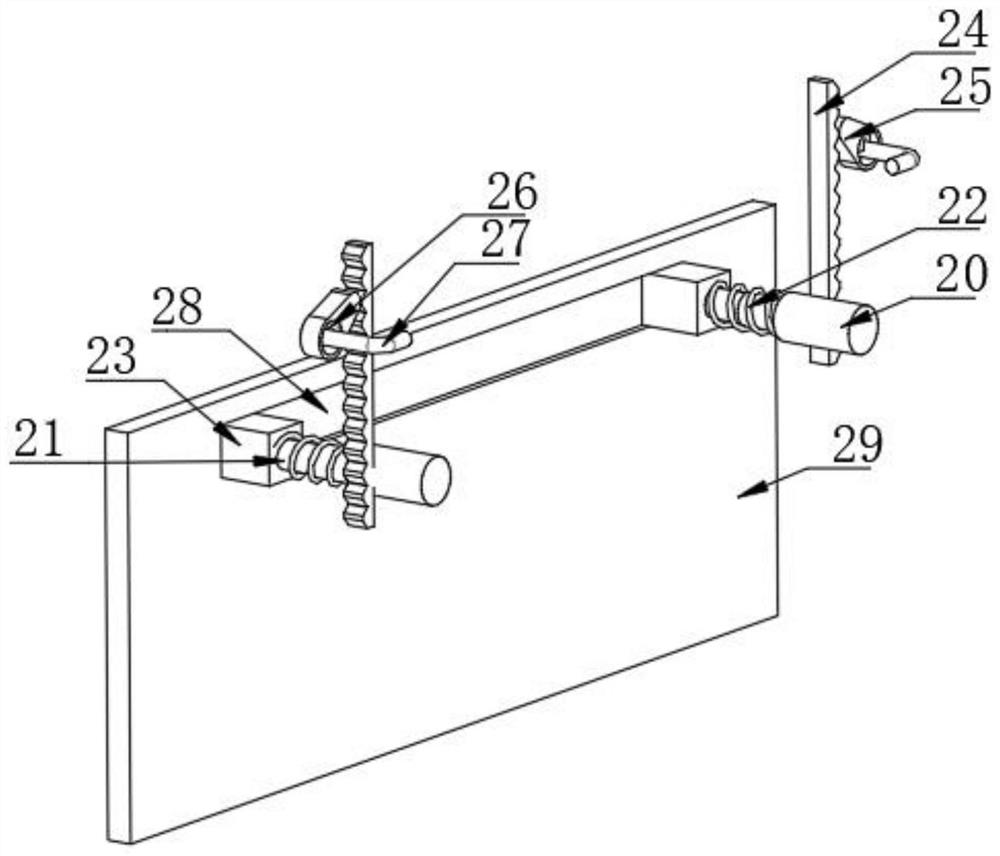

[0032] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8, comprising a wallboard body 1, four round rods 2 are arranged on the top of the wallboard body 1, and the outer sides of the four round rods 2 are fixedly connected with a first pulley 3, and the outer side of the first pulley 3 is provided with a first belt 4 , the outer side of one round rod 2 is fixedly connected with the second pulley 5, the number of the second pulley 5 is set to three, the second belt 6 is arranged on the outer side of the second pulley 5, and the outer side of one of the second pulley 5 A support plate 7 is rotatably connected, and one side of the support plate 7 is respectively fixedly connected with a first telescopic rod 8 and a first spring 9. The first spring 9 is arranged on the outside of the first telescop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com