A parallel double brace gate valve

A double-stay gate and valve plate technology is applied to valve details, valve devices, sliding valves, etc., which can solve problems such as failure to open and close, gate valves that cannot be closed normally, and jamming, and achieve good stability and reliability. Extend the service life and improve the effect of protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

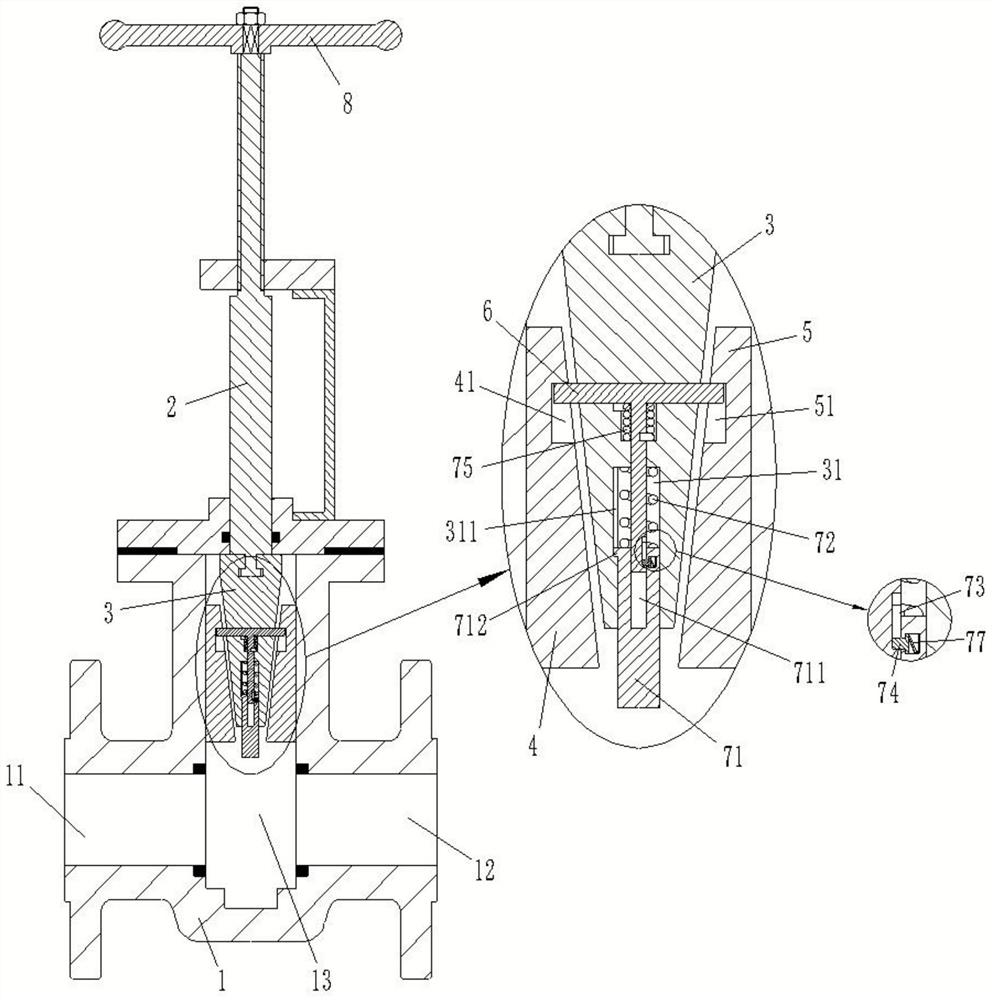

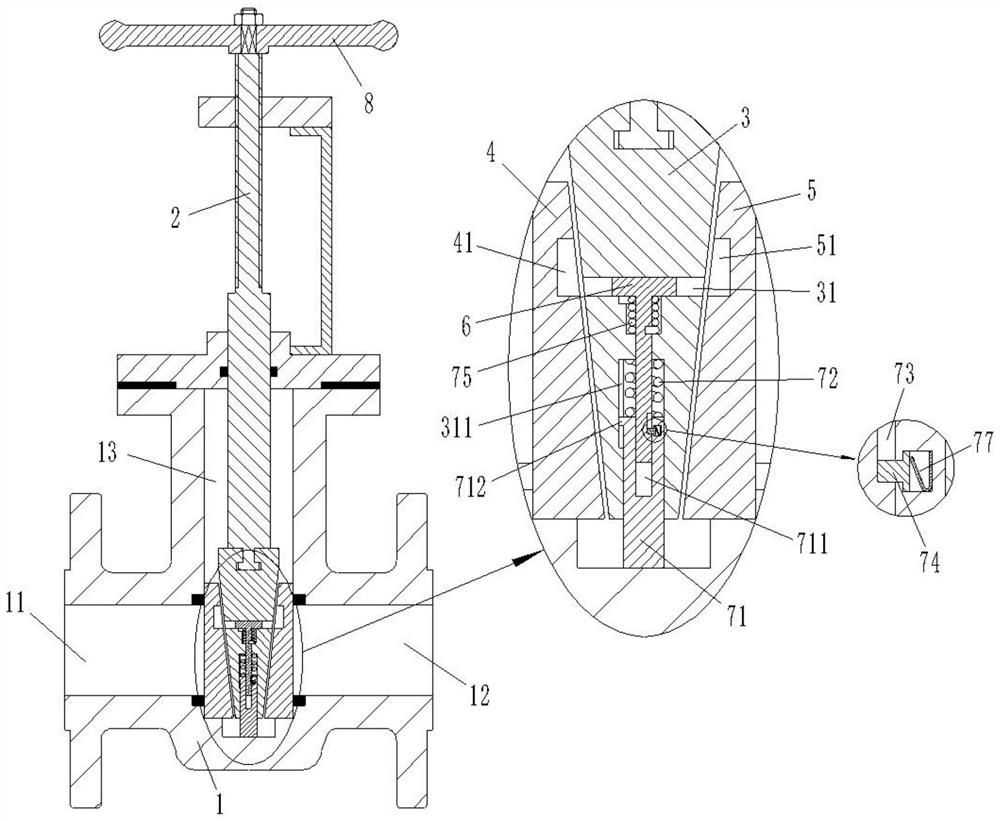

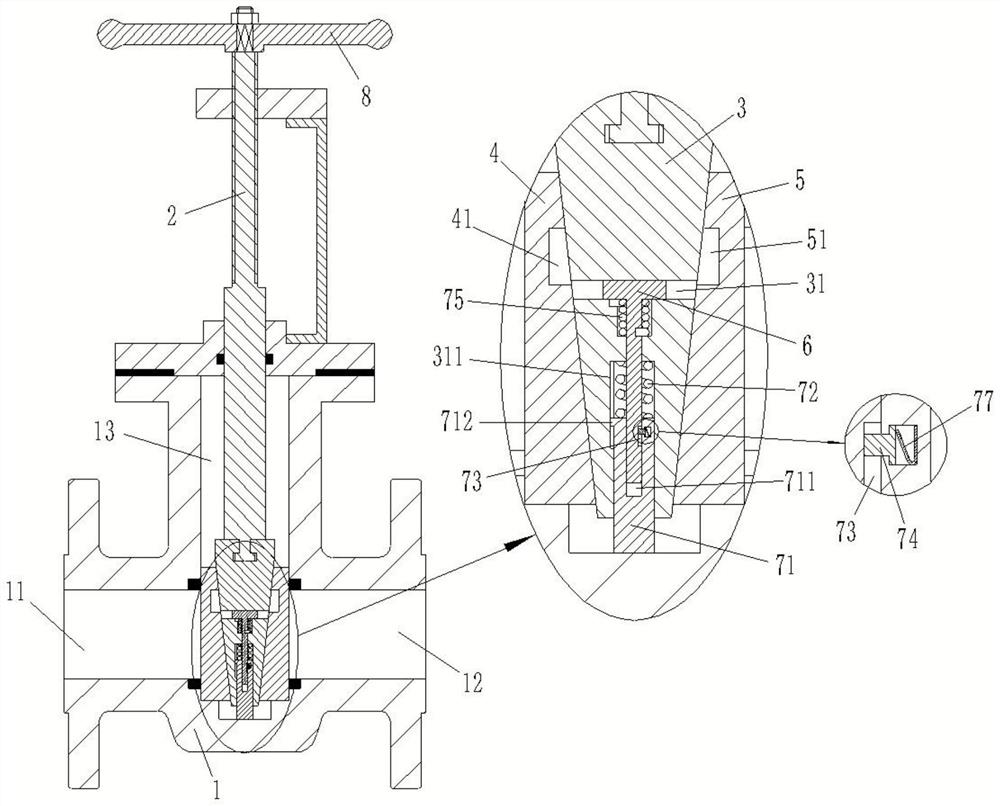

[0024] combine Figure 1 to Figure 6 As shown, the parallel double support plate gate valve of this embodiment includes a valve body 1 , a valve stem 2 , a wedge pressing block 3 , a first valve plate 4 , a second valve plate 5 and a rotating shaft 6 .

[0025] The valve body 1 is provided with an inlet 11 , an outlet 12 and a control hole 13 , wherein the control hole 13 passes through between the inlet 11 and the outlet 12 .

[0026] The wedge pressing block 3 is located inside the control hole 13 and can reciprocate along the axial direction of the control hole 13 . At the same time, the wedge pressing block 3 is provided with a T-shaped hole 31 connecting the two wedge surfaces and the bottom surface. The rotating shaft 6 is a T-shaped shaft, which is located in the T-shaped hole 31 of the wedge pressing block 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com