Noise testing method and device

A noise test and noise technology, applied in the field of noise test methods and devices, can solve the problems of wasting manpower and material resources, prolonging the product development cycle, and uncertain relations, etc., to reduce development costs, shorten product development cycles, and save manpower and material resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

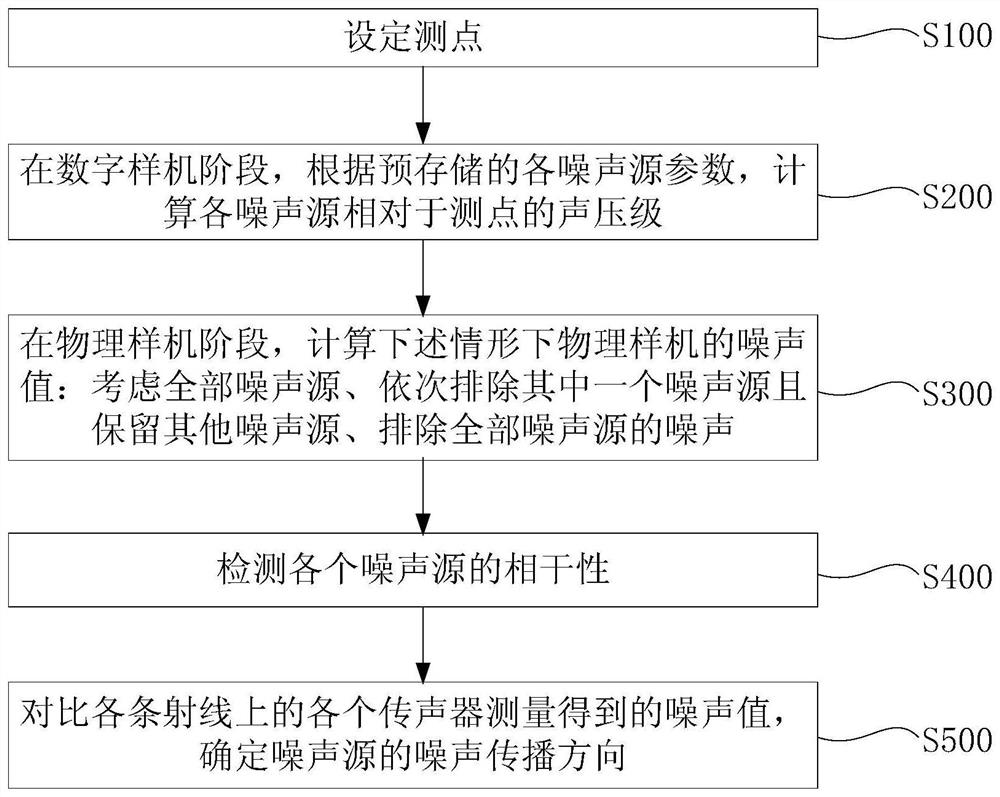

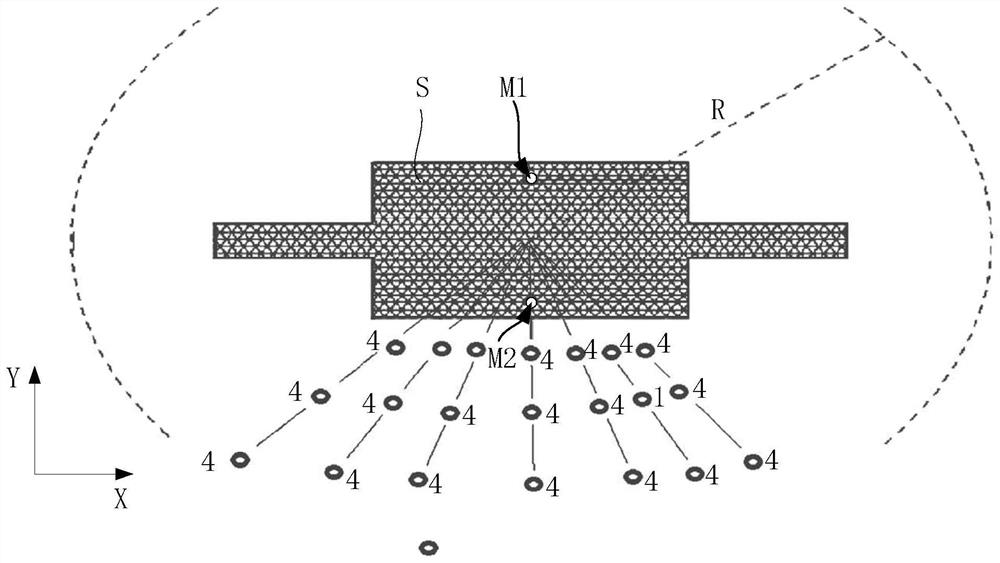

[0075] Combine below Figure 1 to Figure 7 The technical solution provided by the present invention is described in more detail.

[0076] During the research and development of construction vehicles, the noise of the designed products needs to meet the relevant construction machinery noise limit requirements.

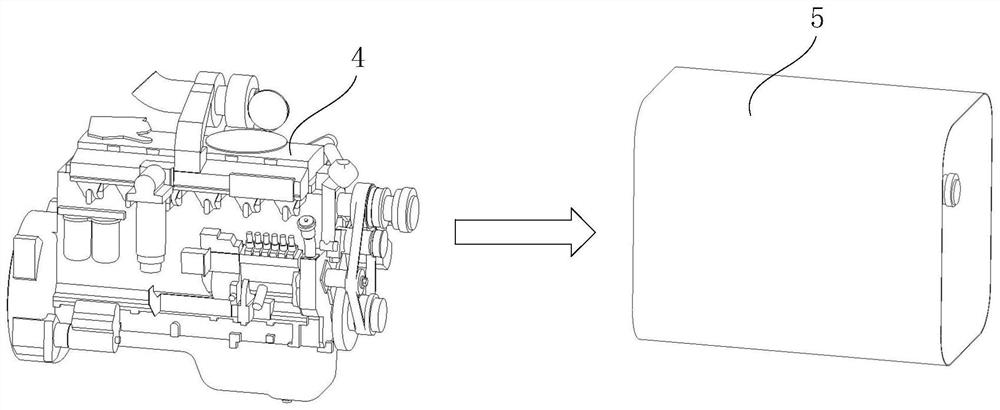

[0077] The noise sources of engineering vehicles mainly include engine 1, fan 3, and intake and exhaust components 2. The power of the engine 1 is large, so the noise is high. The fan 3 is used for cooling, and has a large diameter and a high rotating speed, so it is also noisy. The noise generated by the intake and exhaust assembly 2 during the intake and exhaust processes cannot be ignored. These factors together lead to the large radiation noise of the whole machine. The noise testing method provided by the embodiment of the present invention can predict the noise situation of each main noise source of the vehicle in the state of the whole vehicle, so as to provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com