A Welding Seam Defect Computer Imaging and Defect Recognition System

A defect identification and computer technology, applied in the direction of optical testing defects/defects, optics, instruments, etc., can solve the problems of complex structure and high price, and achieve the effect of reducing testing cost and shortening product development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

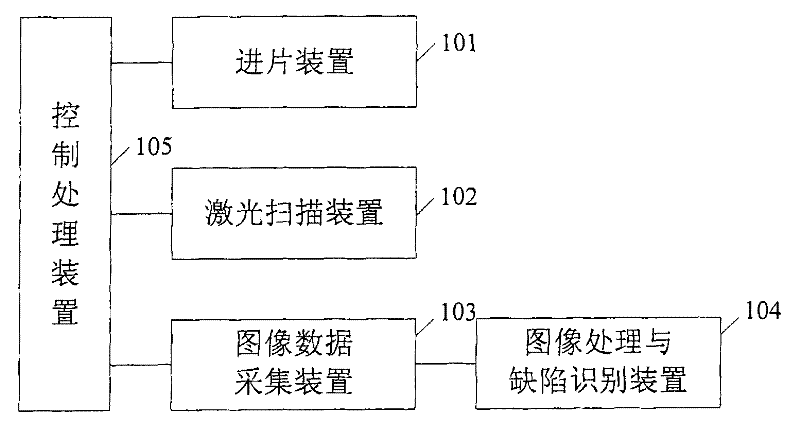

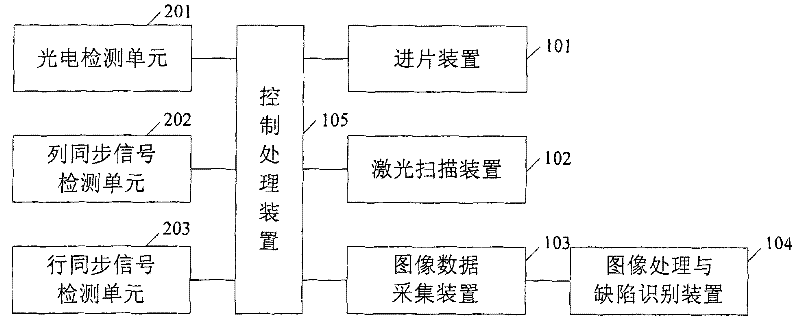

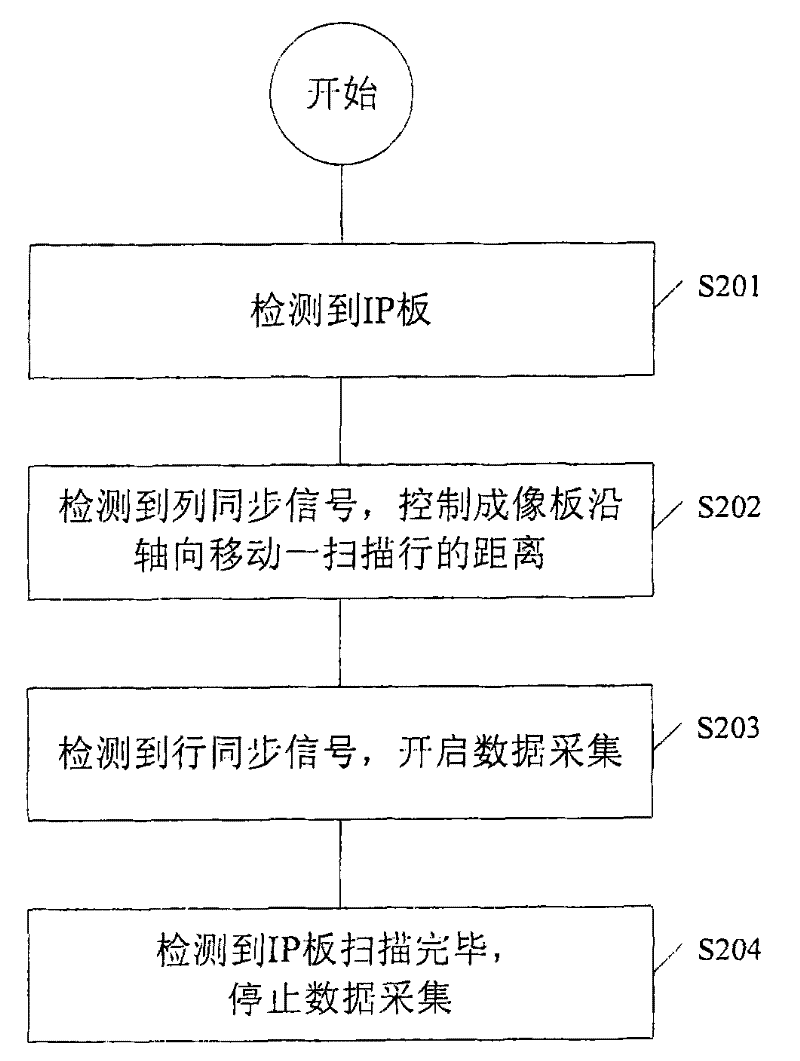

[0015] figure 1 It is a system logic block diagram of the embodiment of the present invention. like figure 1 As shown, the system includes: a film feeding device 101, which includes an inner drum structure for attaching a curved imaging plate, and the film feeding device is used to drive the imaging plate to move along the axis of the inner drum structure; The laser scanning device 102 is used to scan the imaging plate with a laser, and realizes the progressive scanning of the imaging plate along with the movement of the imaging plate; the image data acquisition device 103 is used to collect the imaging plate Excited fluorescent information, converting the fluorescent information into digital information; image processing and defect identification device 104, used to process the digital information to generate weld image information, and per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com