Unmanned aerial vehicle tunnel defect detection method and system

A defect detection and UAV technology, applied in radio wave measurement systems, neural learning methods, unmanned aircraft, etc., can solve the problems that cannot meet the requirements of tunnel defect detection, UAV positioning error, weak light, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

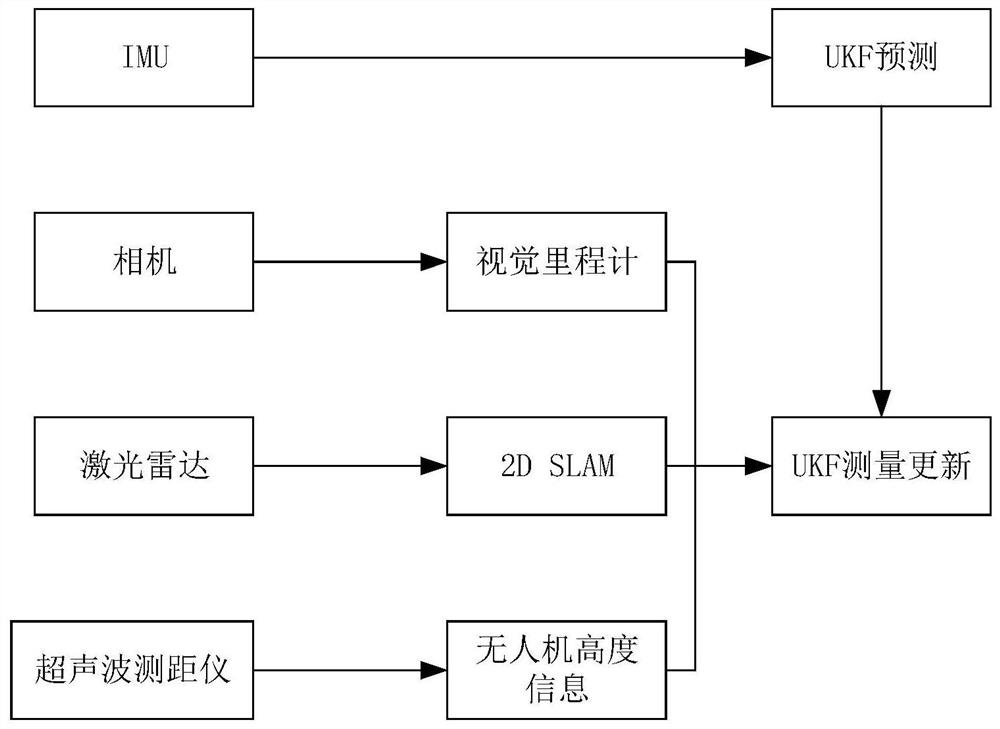

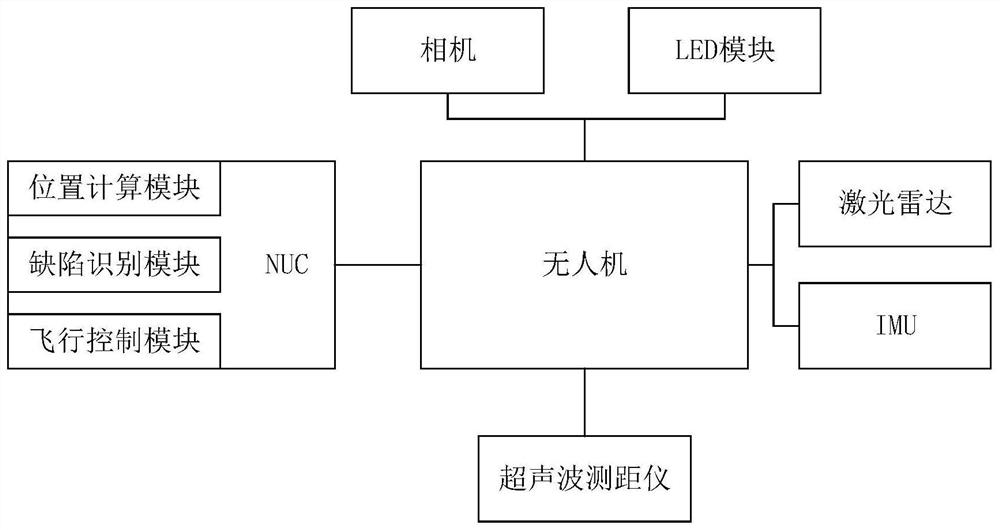

[0039] In this embodiment, the unmanned aerial vehicle for tunnel defect detection is a multi-rotor unmanned aerial vehicle, which is equipped with LED modules, cameras, laser radars, ultrasonic range finders and inertial measurement device IMUs. Illumination enables the camera to collect images at a certain brightness. The radar point cloud data collected by the lidar can realize the positioning and obstacle avoidance of the drone. The camera collects tunnel images for defect detection and can be used as a visual odometer to estimate The attitude information of the UAV, and the ultrasonic rangefinder is used to obtain the height information of the UAV.

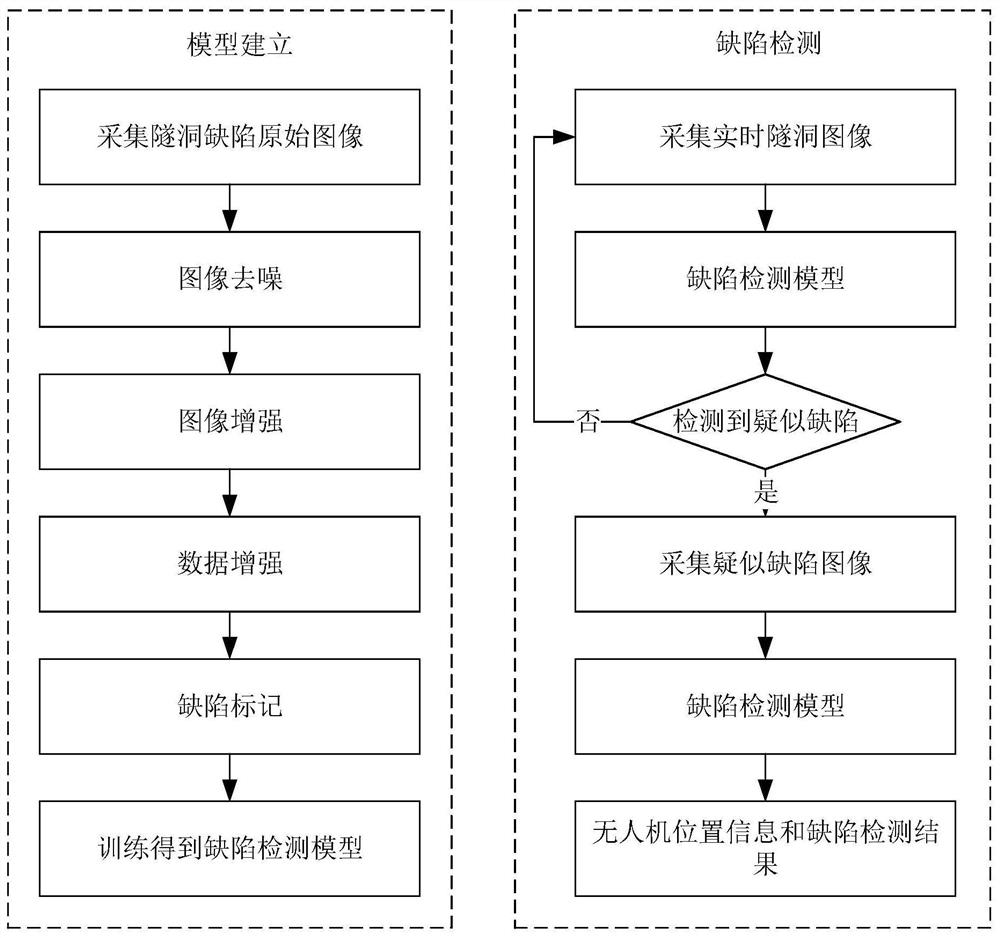

[0040] A method for detecting defects in unmanned aerial vehicle tunnels, such as figure 1 shown, including the following steps:

[0041] S1. The UAV is equipped with an LED module and a camera, based on the LED module and the camera, multiple original images of tunnel defects are collected in the tunnel to obtain an origina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com