A Fuzzy Automatic Control Method of Temperature in Alumina Roasting Furnace

A roasting furnace and alumina technology, applied in the direction of temperature control, non-electric variable control, control/regulation system, etc., can solve the problem of high work intensity for operators, high operational accuracy, high real-time requirements, and unsatisfactory metallurgical needs, etc. problem, to achieve the effect of reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

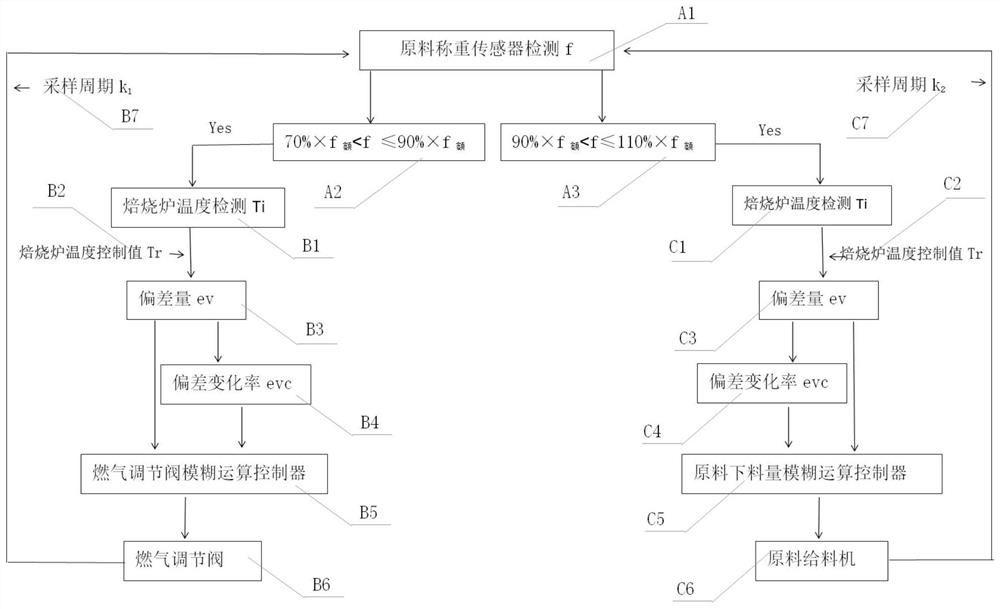

[0038] Such as figure 1 As shown, the fuzzy automatic control method of alumina roasting furnace temperature in the present embodiment is as follows:

[0039] Step 1: Based on the raw material weighing sensor in the roaster, collect the actual value f of the raw material cutting amount at the time point k of the sampling period;

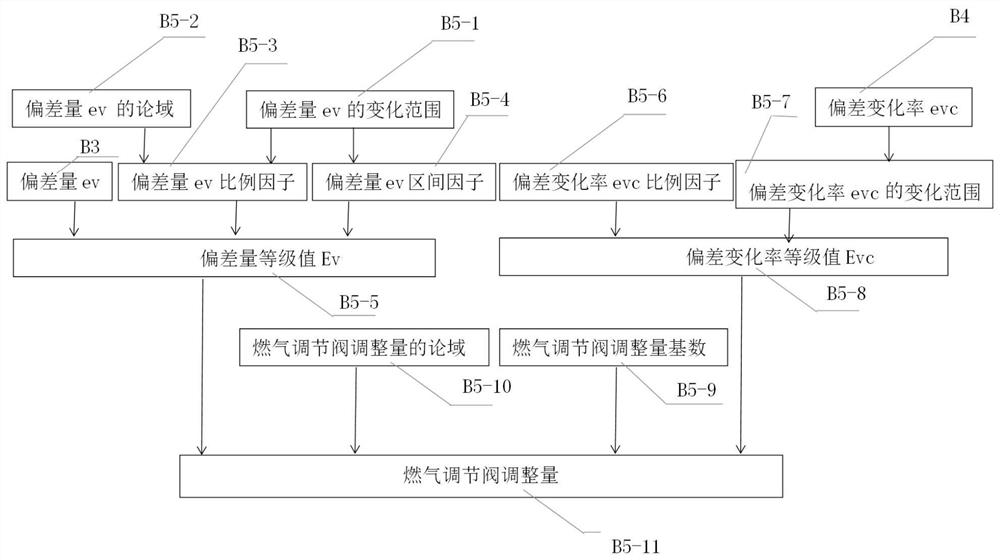

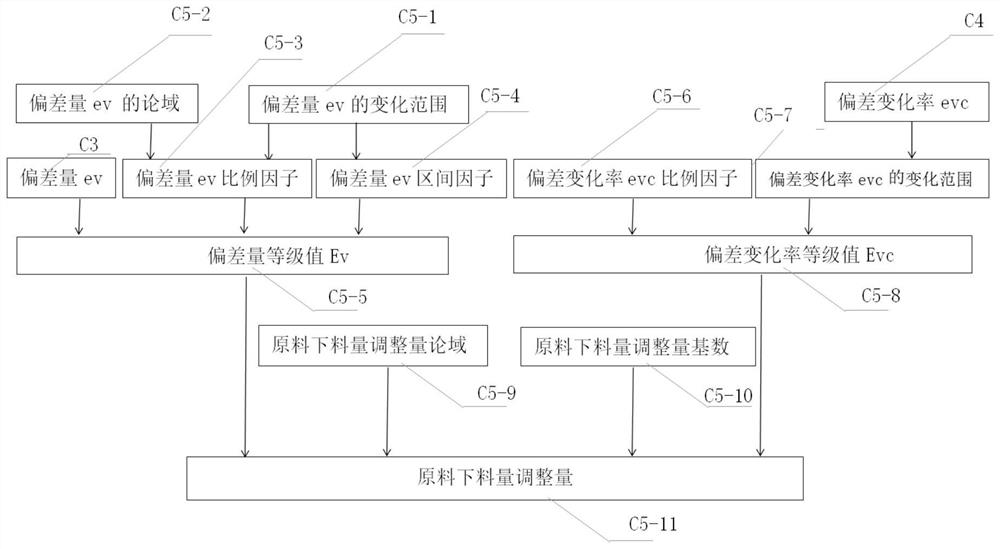

[0040] Step 2: When the actual value f of raw material cutting amount is greater than the rated amount of raw material cutting f 额 70% and the actual value f of raw material cutting amount is less than or equal to the rated amount of raw material cutting f 额 When 90% of , select fuzzy automatic control based on the gas regulating valve V as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com