Positioning and pressing process method for horizontal lamination of stator main iron core

A process method and iron core technology, applied in the field of stator main iron core horizontal stacking positioning and compaction technology, can solve the problem of stator main core damage, horizontal lamination and compaction work is very difficult, and lamination and compaction cannot be solved and other issues to achieve the effect of saving procurement and manufacturing, shortening the repair period, and reducing repair costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

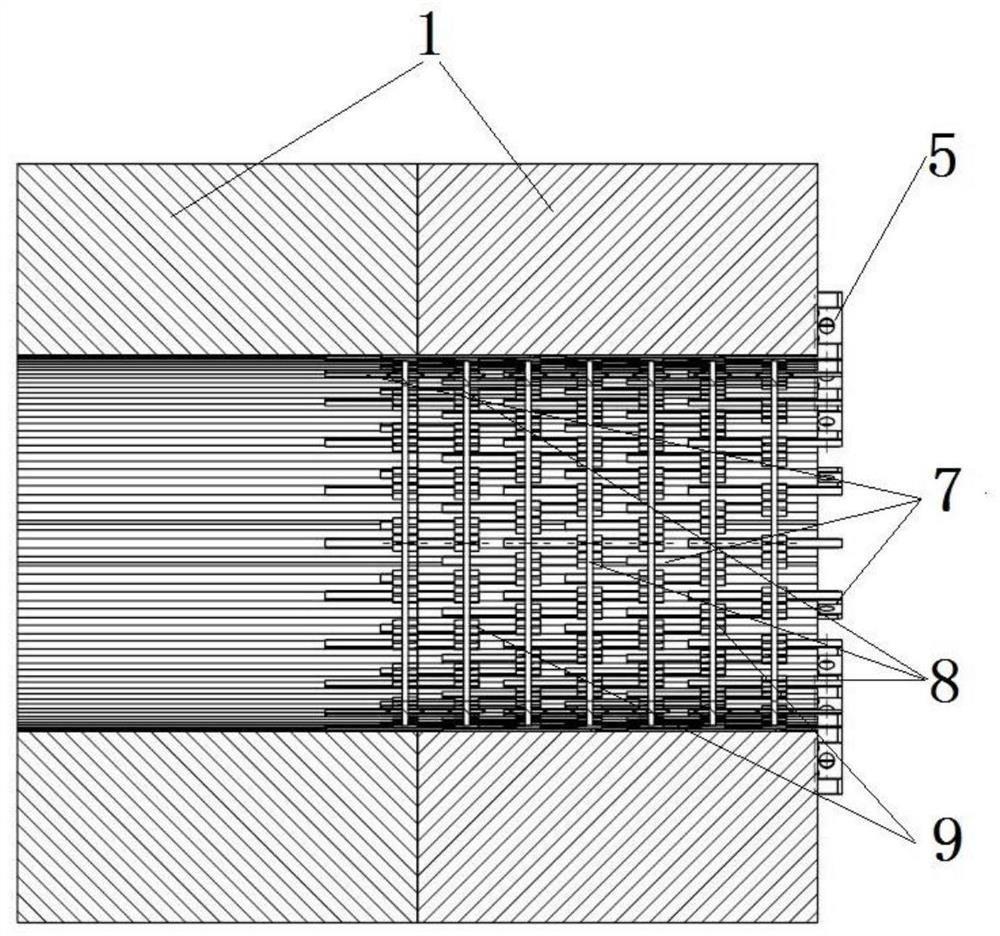

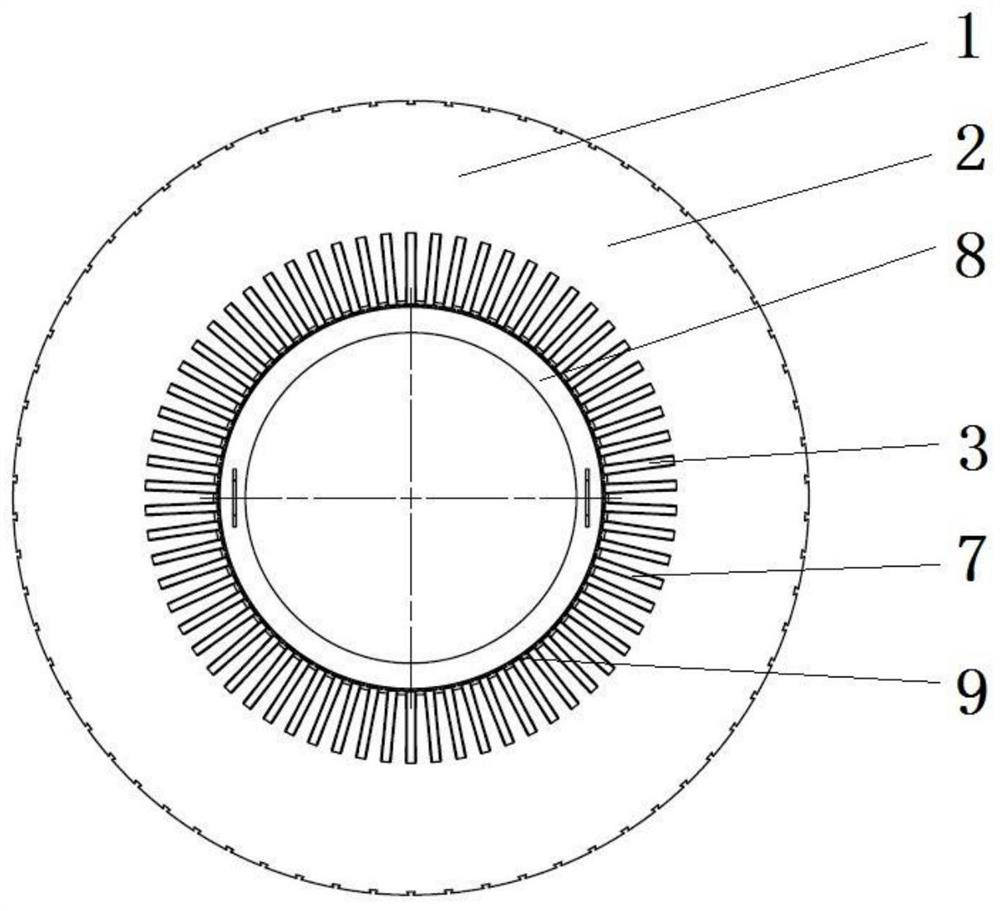

[0031] Horizontal stacking positioning and compacting process of the main iron core of the turbogenerator stator. Its technological implementation process is as follows:

[0032] 1) Remove the stamping plate 2 of the stator main core 1 of the damaged part on site;

[0033] 2) Press figure 1 and figure 2 and image 3 As shown, a positioning support plate 7 is installed in the lower wire slot 3 of the stator main core 1, and a positioning support plate 7 is installed every two lower wire slots 3. The axial length of the positioning support plate 7 in the old stator main core 1 is 300mm. The length of the main stator core 1 protruding out is 200mm, and two support rings 8 are installed on the inner diameter of the old stator main core 1, one is located at the end of the positioning support plate 7, and the other is located in the middle of the positioning support plate 7, the positioning support plate 7 and the support ring 8 The small V-shaped wedges 9 with a taper are fast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com