Method for purification of a biphenol tetraacid composition and a biphenol tetraacid composition

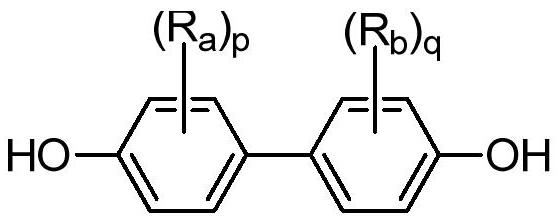

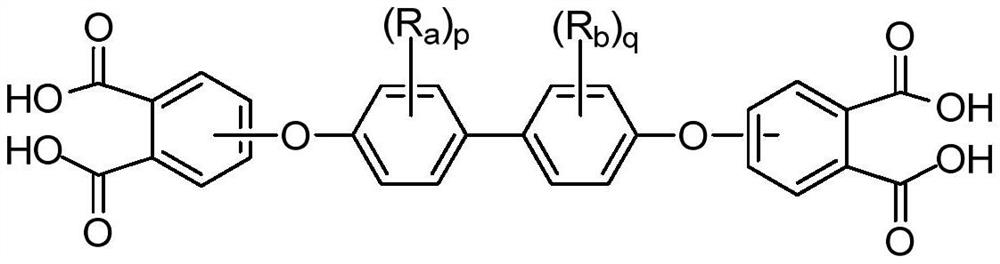

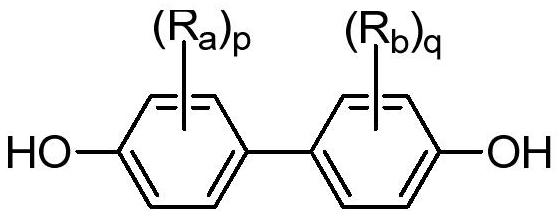

A technology of bisphenol tetraacid and composition, which is applied in the field of purifying bisphenol tetraacid composition and bisphenol tetraacid composition, and can solve problems such as difficulty in providing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] Materials used in the following examples are described in Table 1.

[0038] Table 1

[0039]

[0040]

[0041] In Examples 1 to 31 below, 3,3'-BPoTA with 95.2 to 96.8 wt% was treated with different alcohols, mixtures of alcohol and water, and mixtures of alcohol and o-DCB under different conditions of temperature, time and solids content and 3,4'-BPoTA (total amount, based on the total weight of the BPoTA composition) and bisphenol tetraacid (BPoTA) of 3.2 to 4.8% by weight of bisphenols. The composition of the BPoTA composition was determined by UPLC.

[0042] Ultra Performance Liquid Chromatography (UPLC) analyzes in the following examples were performed on a Waters ACQUITY UPLC BEH C18 1.7 μm 2.1 x 50 mm column at 35°C. PDA detection was performed at 232 nm with a flow rate of 0.313 mL / min. Gradient method with acetonitrile and acidic water (4L DI H 2 O+3mL 85%H 3 PO 4 ) with a dual-solvent system.

[0043] Residual levels of all metals (sodium, potassiu...

Embodiment 7 to 13

[0046] Examples 7 to 13 used a BPoTA composition of 93.98 mol% BPoTA isomer (95.72 wt%); 5.31 mol% (3.20 wt%) bisphenol as determined by HPLC at 232nm and 254nm.

Embodiment 2

[0050] A 500 mL beaker with a mechanical stirrer was charged with IPA (63 g) and then stirred at 175 rpm. The BPoTA composition (27.28 g, 27.0 g dry mass, 96.34% purity, 50.57 mmol) was then added in portions over 2 to 4 minutes. The mixture was stirred at ambient temperature for 60 minutes. Next, filter the slurry through a mesoporous glass funnel. The filter cake was washed with IPA (50 g) at ambient temperature without stirring. The orange filtrate was discarded, and the solid was further dried in a vacuum (0.4 inches Hg) oven at 60 to 70°C overnight to provide 25.11 g of a white solid in 96.5% yield. UPLC: 98.11 mol% BPoTA isomers; 0.49 mol% (0.26 wt%) bisphenol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com