Preparation method of polyimide organic solvent nanofiltration membrane containing spirobiindane structure

A polyimide and organic solvent technology, which is applied in the field of preparation of polyimide organic solvent nanofiltration membranes containing spirobisindane structure, can solve the problem of strong toxicity of chemical solvents, unstable performance of polyamic acid, and difficulty in processing problems such as film, to achieve the effect of enhancing compaction resistance and long-term operation stability, simple and easy preparation method, and improving solvency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

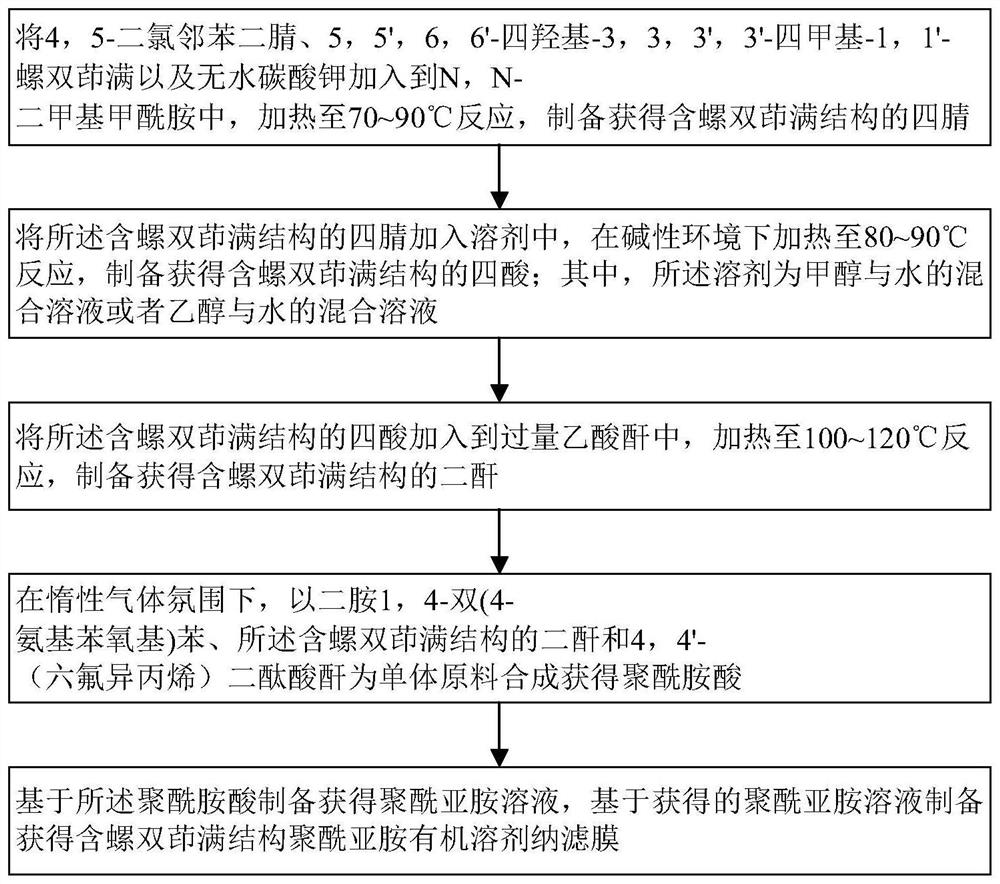

[0040] see figure 1 , a preparation method of a polyimide organic solvent nanofiltration membrane containing a spirobisindan structure according to an embodiment of the present invention includes the following steps:

[0041]S1: 4,5-dichlorophthalonitrile, 5,5',6,6'-tetrahydroxy-3,3,3',3'-tetramethyl-1,1'-spirobisindane (TTSBI) and anhydrous potassium carbonate are added to N,N-dimethylformamide, heated to 70~90℃ to react to obtain tetranitrile containing spirobisindane structure; exemplarily preferred, the reaction time is 3~ 4h;

[0042] S2: adding the tetranitrile containing the spirobisindane structure into a solvent, and heating to 80-90° C. in an alkaline environment to react to obtain the tetraacid containing the spirobisindane structure; wherein the solvent is methanol and A mixed solution of water or a mixed solution of ethanol and water; preferably, the solvent is a methanol / water or ethanol / water mixed solution with a volume ratio of 1:1; the alkaline environment ...

Embodiment 1

[0061] A preparation method of a polyimide organic solvent nanofiltration membrane containing a spirobisindan structure according to an embodiment of the present invention includes the following steps:

[0062] (1) Preparation of spirobisindane tetranitrile: 5,5',6,6'-tetrahydroxy-3,3,3',3'-tetramethyl-1,1'-spirobisindane was used Recrystallization from methanol, methanol-dichloromethane system; 4,5-dichlorophthalonitrile, 5,5',6,6'-tetrahydroxy-3,3,3',3'-tetramethyl- 1,1'-spirobisindane and anhydrous potassium carbonate were used as monomer raw materials, added to N,N-dimethylformamide, heated to 85°C in an oil bath for 3h reaction; the resulting milky white suspension was added to a large amount of pure water Stirring in medium, dilute hydrochloric acid is added dropwise to neutralize excess potassium carbonate until the system is acidic; the product is suction filtered, washed, and dried in vacuum to finally obtain a tetranitrile containing a spirobisindane structure.

[0...

Embodiment 2

[0068] A preparation method of a polyimide organic solvent nanofiltration membrane containing a spirobisindan structure according to an embodiment of the present invention includes the following steps:

[0069] (1) Preparation of spirobisindane tetranitrile: 5,5',6,6'-tetrahydroxy-3,3,3',3'-tetramethyl-1,1'-spirobisindane was used Recrystallization from methanol, methanol-dichloromethane system; 4,5-dichlorophthalonitrile, 5,5',6,6'-tetrahydroxy-3,3,3',3'-tetramethyl- 1,1'-spirobisindane and anhydrous potassium carbonate were used as monomer raw materials, added to N,N-dimethylformamide, heated to 85°C in an oil bath for 3h reaction; the resulting milky white suspension was added to a large amount of pure water Stirring in medium, dilute hydrochloric acid is added dropwise to neutralize excess potassium carbonate until the system is acidic; the product is suction filtered, washed, and dried in vacuum to finally obtain a tetranitrile containing a spirobisindane structure.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com