Flexible drive knee joint rehabilitation robot

A rehabilitation robot and knee joint technology, applied in the field of rehabilitation medicine, can solve problems such as secondary injury of the knee joint, limited rotation angle, and limited range of knee joint flexion and extension angles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to illustrate the technical solutions of the embodiments of the present invention more clearly, the technical solutions in the embodiments will be described in detail below in conjunction with the accompanying drawings.

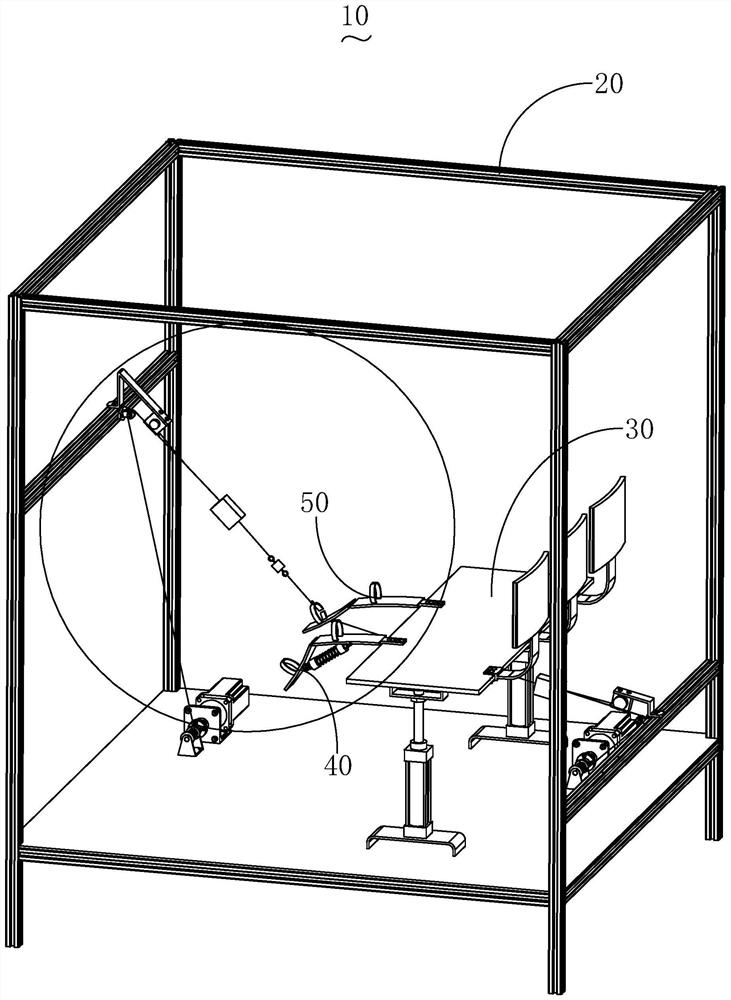

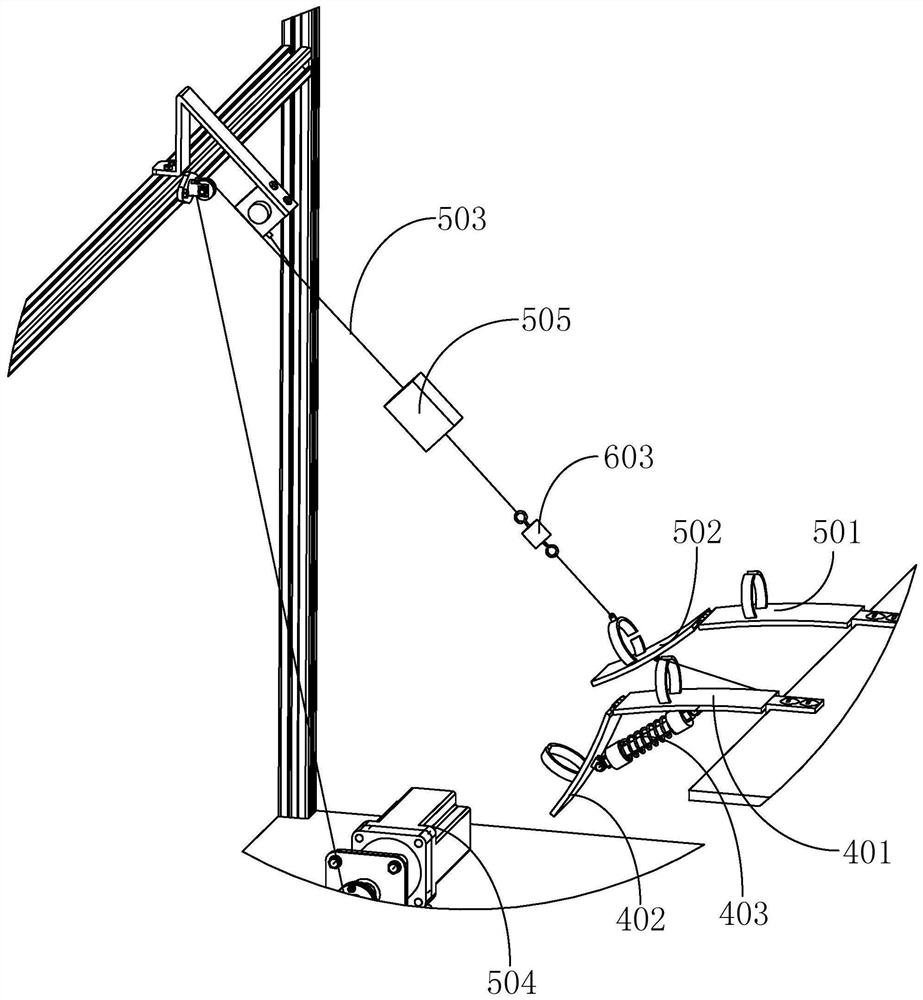

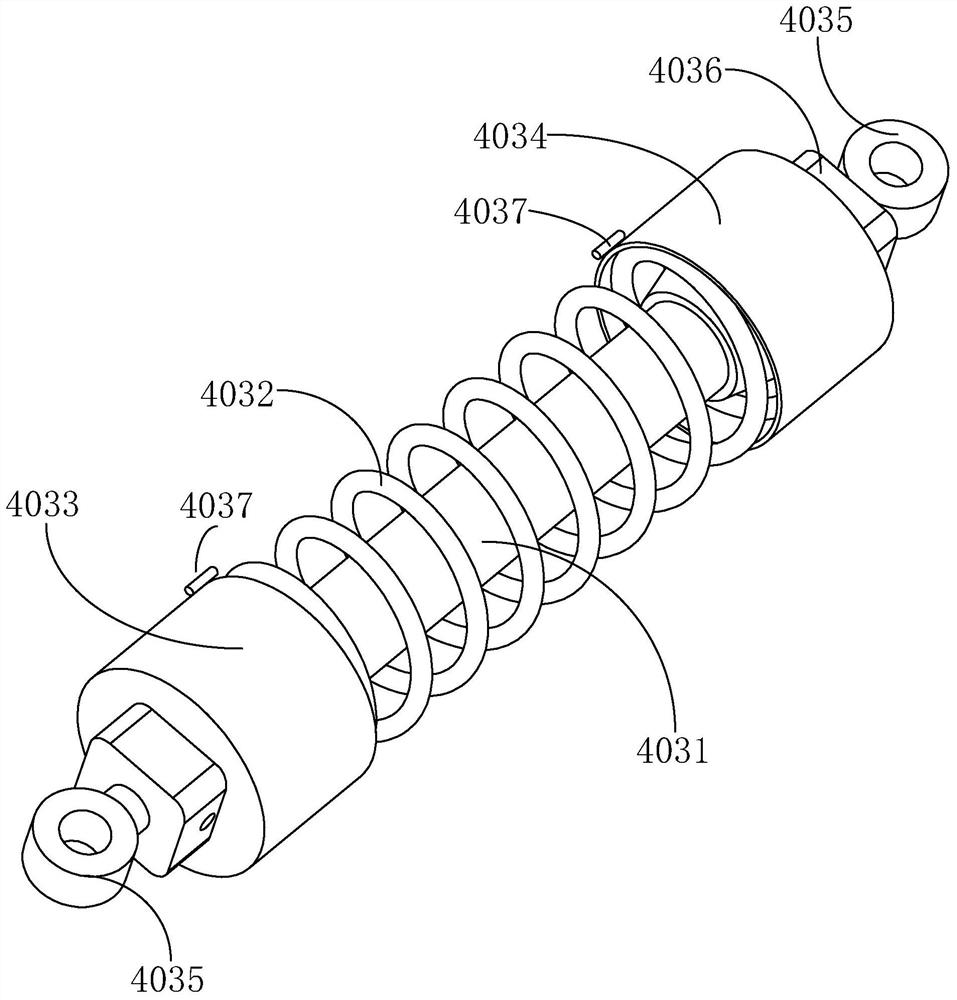

[0025] Please see figure 1 , figure 2 and image 3, the flexible drive knee joint rehabilitation robot 10 includes a frame 20, a seat 30, a left training mechanism 40, and a right training mechanism 50. The left side and the right side of the chair 30, the left training mechanism 40 includes a left thigh section 401, a left calf section 402, a novel parallel spring type pneumatic artificial muscle driver 403, and the upper end of the left thigh section 401 is fixedly connected with the seat 30 , the lower end of the left thigh section 401 is rotationally connected with the upper end of the left calf section 402, and the two ends of the novel parallel spring type pneumatic artificial muscle driver 403 are respectively rotationally connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com