Multi-section combined sewage treatment system

A sewage treatment system and combined technology, which is applied in the direction of fixed filter elements, filtration separation, chemical instruments and methods, etc., can solve the problems of filter blockage, failure to ensure that the sewage meets the discharge requirements, and can only be shut down for cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

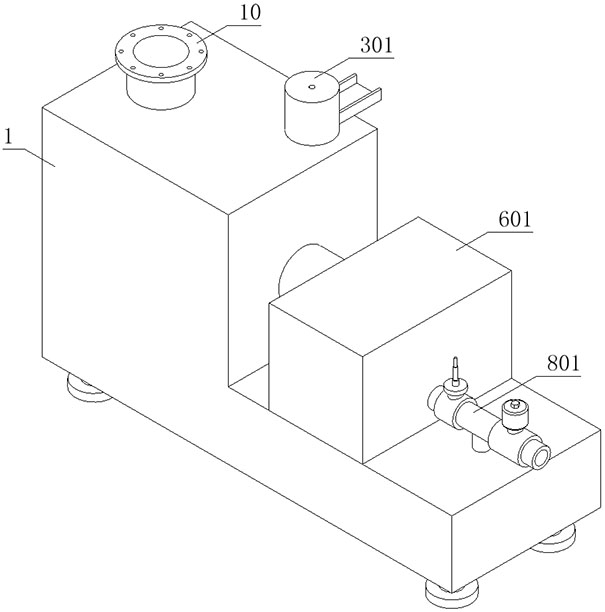

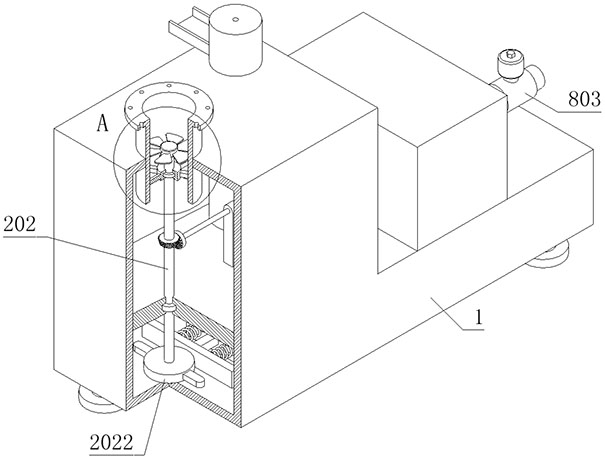

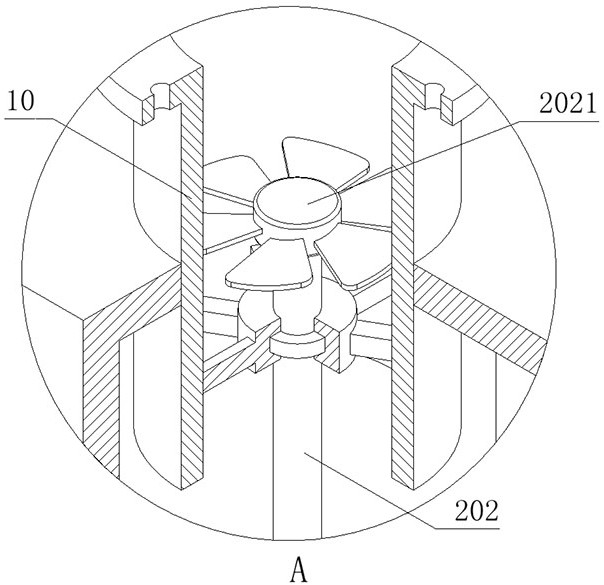

[0076] as attached figure 1 to attach Figure 17 Shown:

[0077] The present invention provides a multi-stage combined sewage treatment system, which includes a main body 1; a water inlet pipe 10 is fixedly installed on the top of the main body 1, and a driving part 2 is installed inside the water inlet pipe 10, and a partition plate 11 is fixedly installed inside the main body 1 , and the bottom of the partition 11 is installed with a limiting part 4, and the top of the partition 11 is fixedly installed with a cleaning part 7, and the inner bottom side of the main body 1 is fixedly installed with a fixed block 12 and a controller 13; The flow part 3 is installed on the main body 1; the push part 5 is installed inside the main body 1; the filter part 6 is installed on the top of the main body 1, and the right side of the filter part 6 is installed with a drainage part 8; The return part 9 is installed inside the main body 1 .

[0078] like Figure 4 and Figure 14 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com