Material veneer cutting device for manufacturing hardcover product box

A technology of cutting device and bill of materials, which is applied to the device and coating of surface coating liquid, which can solve the problems of expensive and cumbersome materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

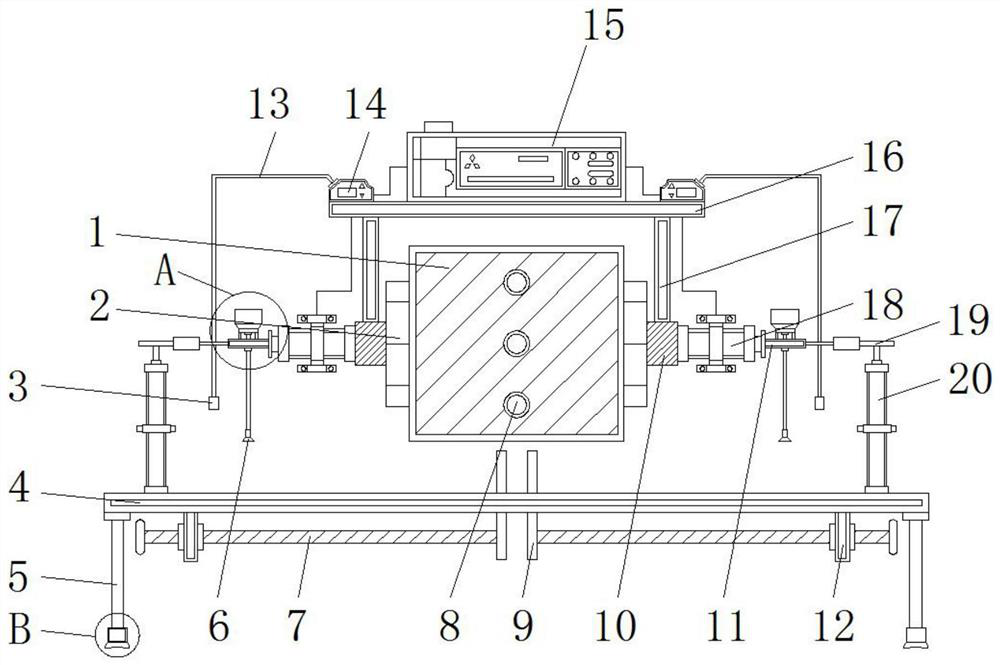

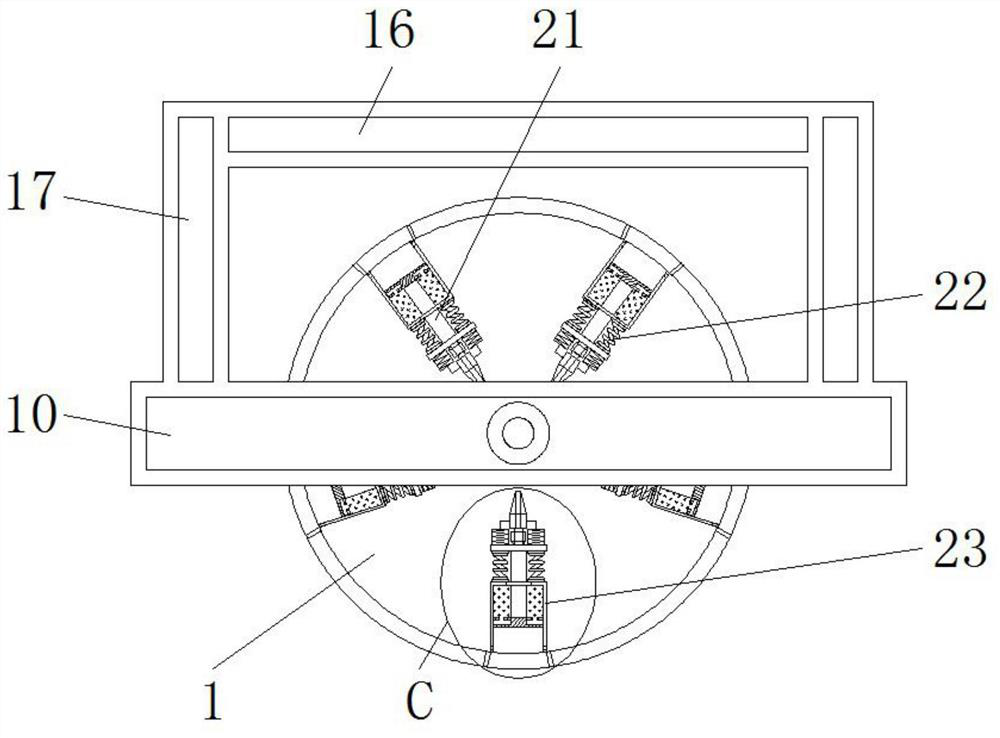

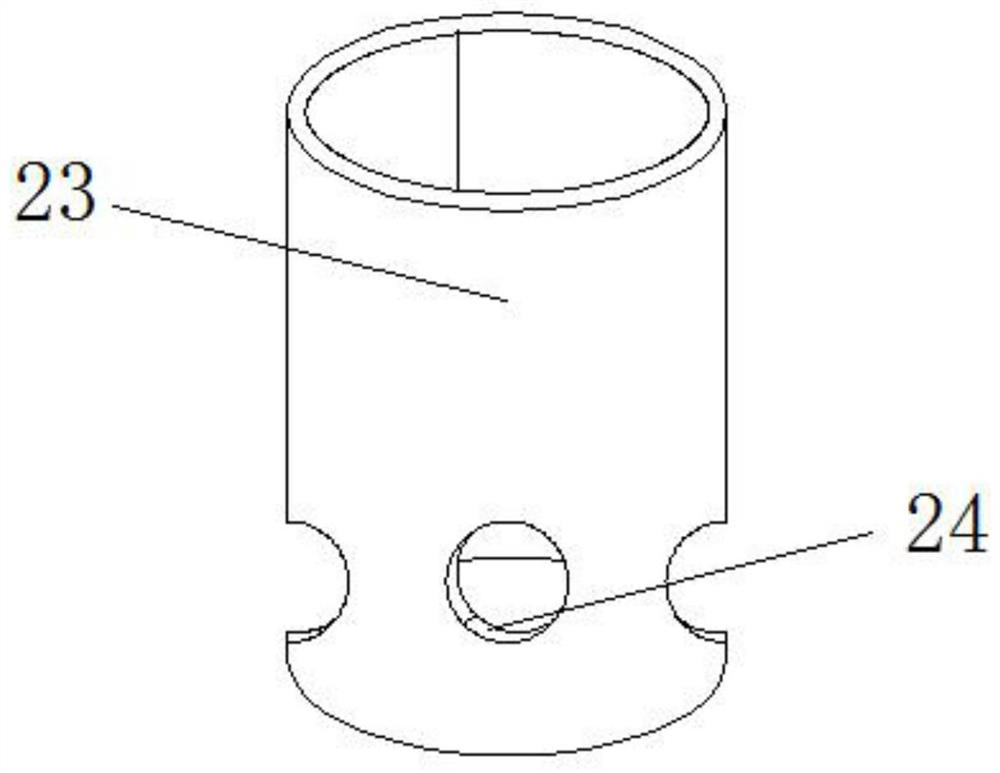

[0038] see Figure 1-9 , according to an embodiment of the present invention, a material veneer cutting device for hardcover product box production includes a local oil passing mechanism, a joint oil passing mechanism is provided on both sides of the local oil passing mechanism, and a thickness adjustment mechanism is arranged under the joint oil passing mechanism , a clamping mechanism is provided under the thickness adjustment mechanism, an edge sensing mechanism is provided on the joint oil passing mechanism, a base fixing mechanism is provided under the clamping mechanism, the partial oil passing mechanism includes a partial oil passing cylinder 1, and the inside of the partial oil passing cylinder 1 Partial ink fountains 23 are installed, and the local ink fountains 23 are evenly distributed along the inside of the partial oil passage 1, and the partial ink fountains 23 are provided with five groups. The lower end of the ink fountain 23 is symmetrically distributed, and t...

Embodiment 2

[0048] see Figure 1-9 , for the material veneer cutting device for making hardcover product boxes, there are combined oil passing mechanisms on both sides of the local oil passing mechanism, a thickness adjustment mechanism is installed under the joint oil passing mechanism, and a clamping mechanism is installed under the thickness adjustment mechanism , the joint oil passing mechanism is provided with an edge sensing mechanism, and the clamping mechanism is provided with a base fixing mechanism. The partial oil passing mechanism includes a partial oil passing cylinder 1, and a partial ink fountain 23 is installed inside the partial oil passing cylinder 1, and the partial ink fountain 23 is arranged along the Partially distributed inside the oil cylinder 1, and the local ink fountain 23 is provided with five groups, and the outer surface of the local ink fountain 23 is provided with a local oil outlet hole 24, and the local oil outlet hole 24 is symmetrically distributed along...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com