Clean production device for aluminum alloy casting and forging

A clean production, aluminum alloy technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

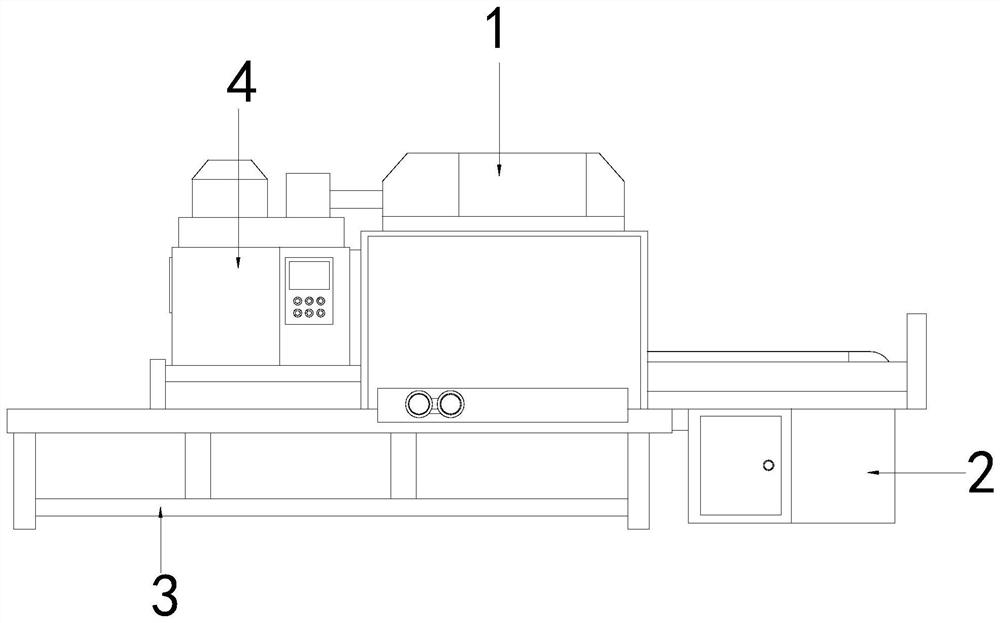

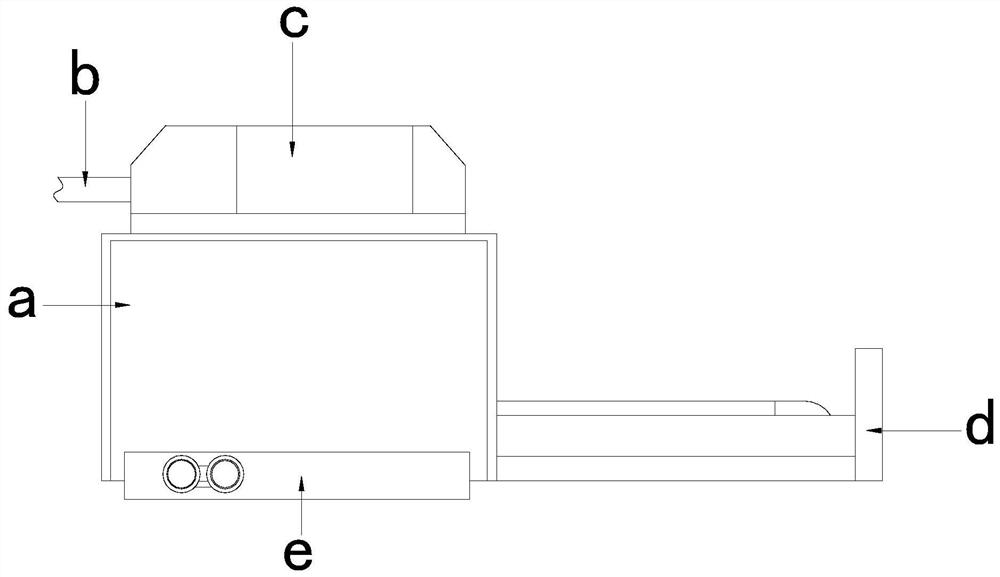

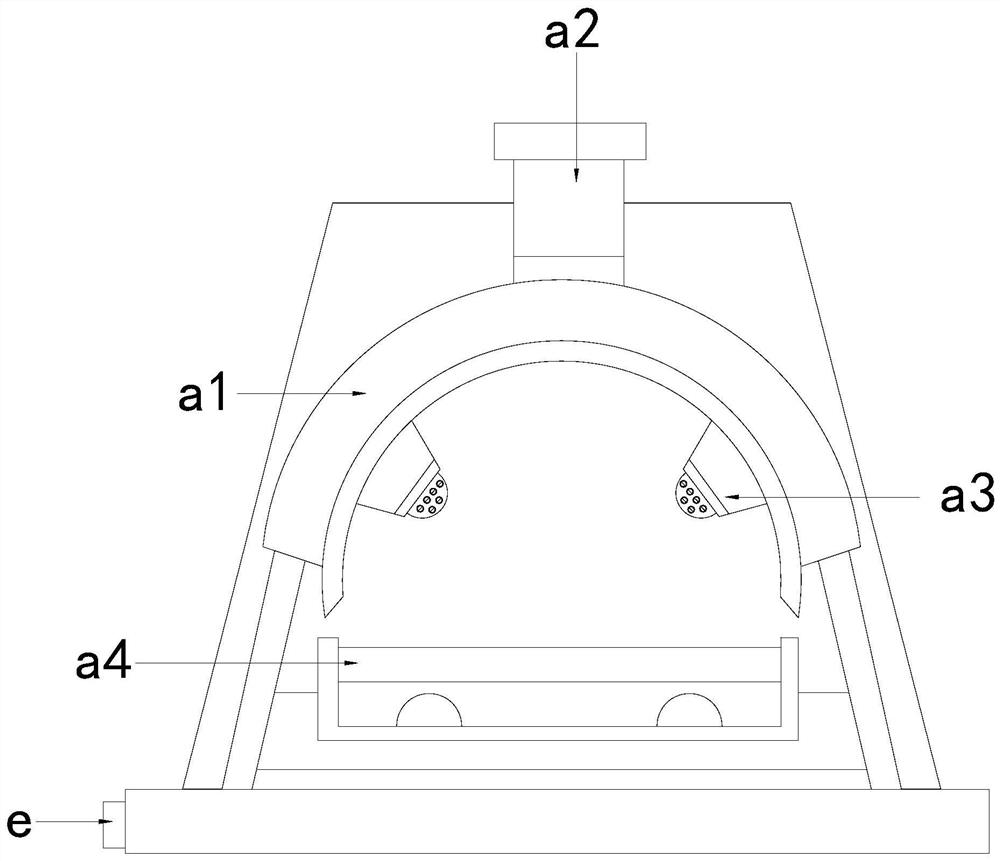

[0026] see Figure 1-Figure 4 , the present invention provides a technical solution for aluminum alloy casting and forging clean production equipment: its structure includes: a cleaning chamber body 1, a limit box 2, a supporting steel frame 3, and a control mechanism 4, and the control mechanism 4 is installed on the cleaning chamber body 1 The side is locked with the cleaning chamber body 1, and a supporting steel frame 3 is provided under the cleaning chamber body 1, and the supporting steel frame 3 is locked with the cleaning chamber body 1, and a limit position is provided on the right side of the supporting steel frame 3 Box 2, the limit box 2 is buckled with the supporting steel frame 3, the cleaning chamber body 1 includes an inner chamber device a, a water inlet pipe b, a water storage chamber c, a storage board device d, a return flow tank e, and the water inlet pipe b Installed on the left side of the water storage bin c and buckled with the water storage bin c, an ...

no. 2 example

[0031] see Figure 5-Figure 6 , the present invention provides a technical solution for aluminum alloy casting and forging clean production equipment: its structure includes: the storage plate device d includes a tray device d1, a drawer plate d2, a sleeve d3, a telescopic rod d4, an inner buckle plate d5, Squeeze the bar d6, the drawing plate d2 is installed on the outside of the sleeve d3 and fastened with the sleeve d3, the inner side of the sleeve d3 is embedded with a telescopic rod d4, and the end of the telescopic rod d4 is fastened with the inner buckle d5 , A supporting tray device d1 is arranged above the sleeve d3, and an extrusion strip d6 is locked to the lower end of the inner gusset d5.

[0032] The supporting tray device d1 includes a first supporting plate d11, a second supporting plate d12, and a hinge shaft block d13. The first supporting plate d11 is installed on the left end of the second supporting plate d12 and fastened to the second supporting plate d12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com