Cleaning device for part machining

A cleaning device and parts processing technology, applied in the field of parts processing, can solve the problems of uneven cleaning effect, difficult fan, poor air-drying effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

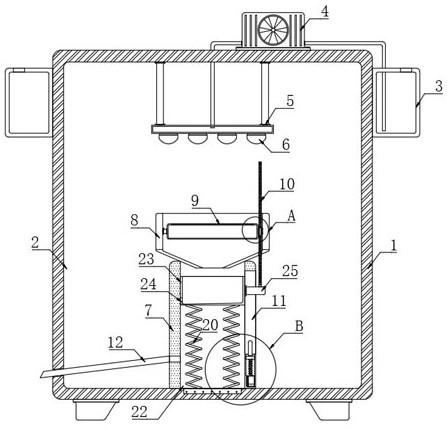

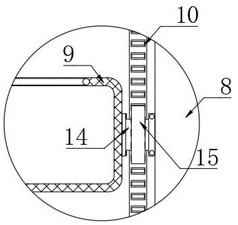

[0029] refer to Figure 1-5 , a cleaning device for parts processing, comprising a housing 1, a plurality of support seats are installed on the lower end of the housing 1 for supporting the housing 1, a cleaning chamber 2 is arranged inside the housing 1, and the inside of the cleaning chamber 2 A support block 7 is installed at the bottom, and a vertical movable groove 22 is provided in the support block 7. The upper end of the support block 7 is fixedly connected with a water collection bucket 8, and a screen frame 9 is arranged in the water collection bucket 8. The upper end surface of the screen frame 9 A net-shaped sliding door is set, through which parts can be put in and taken out, and a transparent airtight door is also installed on the front side of the housing 1, which is convenient for subsequent operation and processing, and the left and right sides of the screen frame 9 are fixedly connected There are rotating rods 14, and each rotating rod 14 is connected to the ...

Embodiment approach

[0030] As an embodiment of the present invention, it also includes a cleaning mechanism. The cleaning mechanism includes an annular water tank 3 fixedly connected to the outer wall of the housing 1. A water pump 4 is installed on the upper end of the housing 1. The water inlet pipe of the water pump 4 extends to the annular water tank. The inner top of 3, the inner top of cleaning chamber 2 are fixedly connected with installation frame 5, and the lower end of installation frame 5 is equipped with a plurality of shower nozzles 6, and the liquid inlet end of a plurality of shower nozzles 6 is all communicated with the outlet pipe of water pump 4.

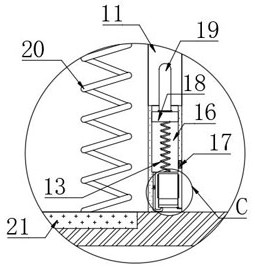

[0031] As an embodiment of the present invention, the inner bottom of the strip-shaped opening 11 is provided with a vertical groove 16, and a trigger mechanism is arranged in the vertical groove 16. The trigger mechanism includes a piston block 18 for sliding up and down in the vertical groove 16, and the piston block The lower end of...

Embodiment 2

[0038] refer to Figure 6-7 The difference between this embodiment and Embodiment 1 is that the piston block 18 is made of conductive material, and the second conductive plate 34 is arranged on the inner walls of both sides of the vertical groove 16, and two hollow holes are arranged obliquely in the cleaning chamber 2. plate 33, the opposite surfaces of the two hollow plates 33 are provided with a plurality of air outlets, the right side of the housing 1 is equipped with a fan 31, the outlet end of the fan 31 is connected with two branch pipes 32, the other ends of the two branch pipes 32 They communicate with the two hollow plates 33 respectively, the positive pole of the external power supply and the second conductive plate 34 on the left are electrically connected by wires, and the negative pole of the external power supply, the fan 31 and the second conductive plate 34 on the right are electrically connected by wires.

[0039] In this embodiment, when the piston block 18 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com