A cold shear automatic steel cutting control method

A control method and automatic technology, applied in rolling mill control devices, manufacturing tools, metal rolling, etc., can solve the problem that it takes a long time to replace the absolute encoder, is inconvenient for post personnel to debug, modify parameters, and the first-stage rolling distance error, etc. problems, to achieve the effect of easy spot inspection and maintenance, easy operation of post personnel, and avoidance of rolling and cutting deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the examples, which are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

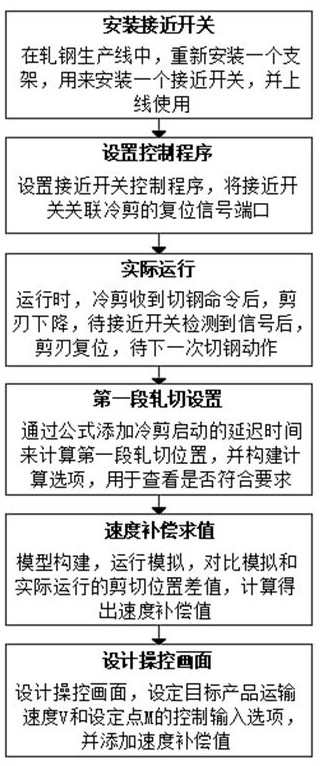

[0031] according to figure 1 As shown, this embodiment proposes a cold shear automatic steel cutting control method, including the following steps:

[0032] Step 1: Install the proximity switch

[0033] In the steel rolling production line, remove the original bracket for installing the absolute encoder and the proximity switch, and reinstall a bracket to install a proximity switch, and use it online;

[0034] Step 2: Set up the control program

[0035] Based on the Siemens PLC400 system, program and set the proximity switch control program. The proximity switch control program is compiled using AMPL (ABB MasterPiece Language). The control program includes: read positioning templat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com