Dual-drive arc-shaped transmission device

A transmission device and double-drive technology, which is applied in the field of double-drive arc-shaped transmission devices, can solve problems such as downtime accidents, affecting the normal production of continuous casting slabs, and poor driving ability of single-drive steel pullers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

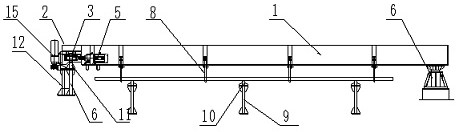

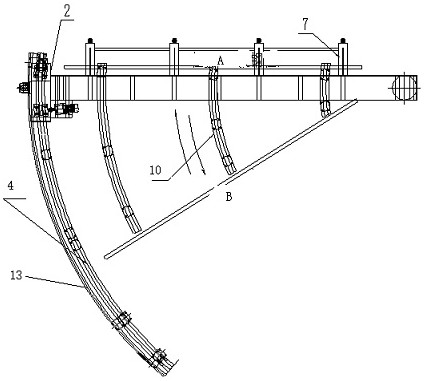

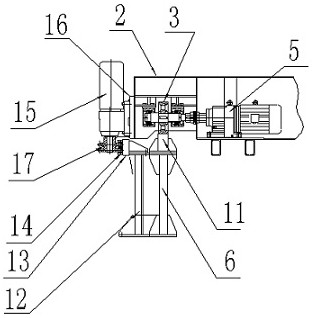

[0017] Below in conjunction with accompanying drawing, the present invention will be further described by examples.

[0018] Refer to attached Figure 1-4 , a dual-drive arc-shaped transmission device, including a dial steel rotating arm 1, an end beam 2, a wheel 3, an arc track A4, a motor reducer 5, a rotating shaft 6, a claw 8, an arc track B10, and an arc track C13, double-row roller chain 14, vertical motor reducer 15, equipment base 16 and double-row sprocket 17, one end of dial steel rotating arm 1 is connected with rotation shaft 6, and the other end of dial steel rotating arm 1 is provided with On the end beam 2, a plurality of evenly arranged dials 8 are arranged on the dial steel rotating arm 1, and the end beam 2 is provided with a wheel 3, the wheel 3 is supported on the arc track 4, and the motor reducer 5 is drivingly connected to the wheel 3; The vertical motor reducer 15 is installed on the end beam 2 through the equipment base 16 welded on the end beam 2. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com