Automatic assembling device for vehicle-mounted relay split washer and working method thereof

An automatic assembly and relay technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve problems such as falling open rings, damaging the surface, and affecting the quality of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

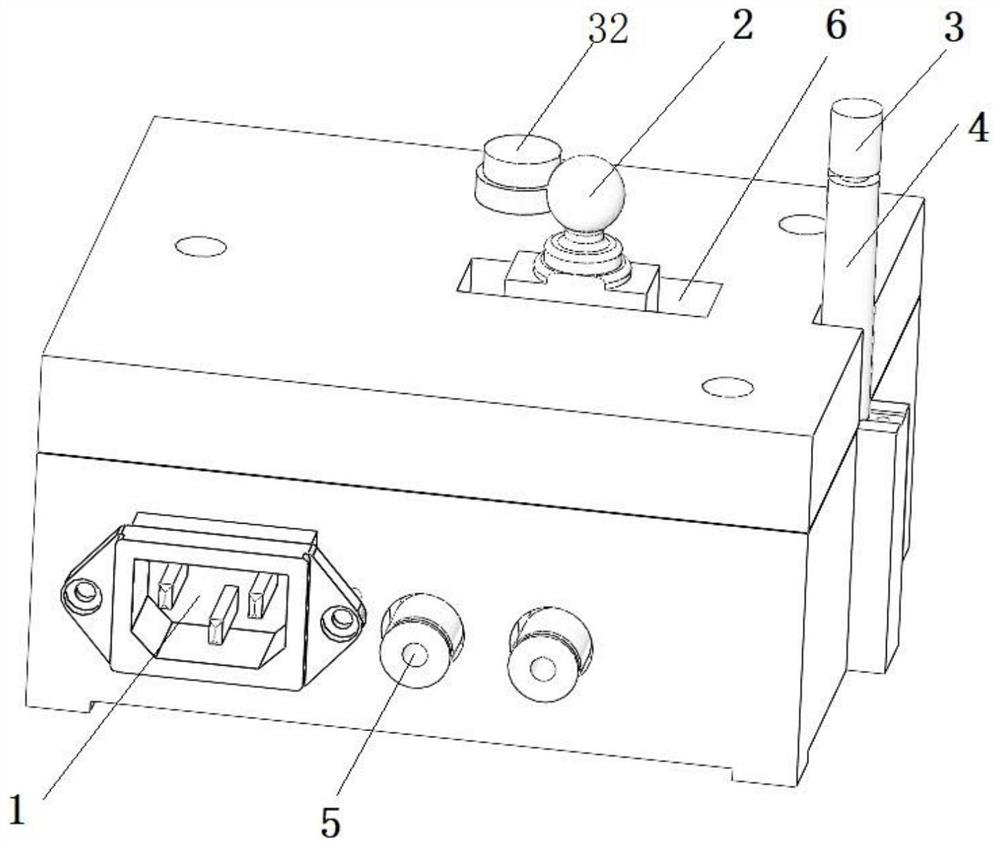

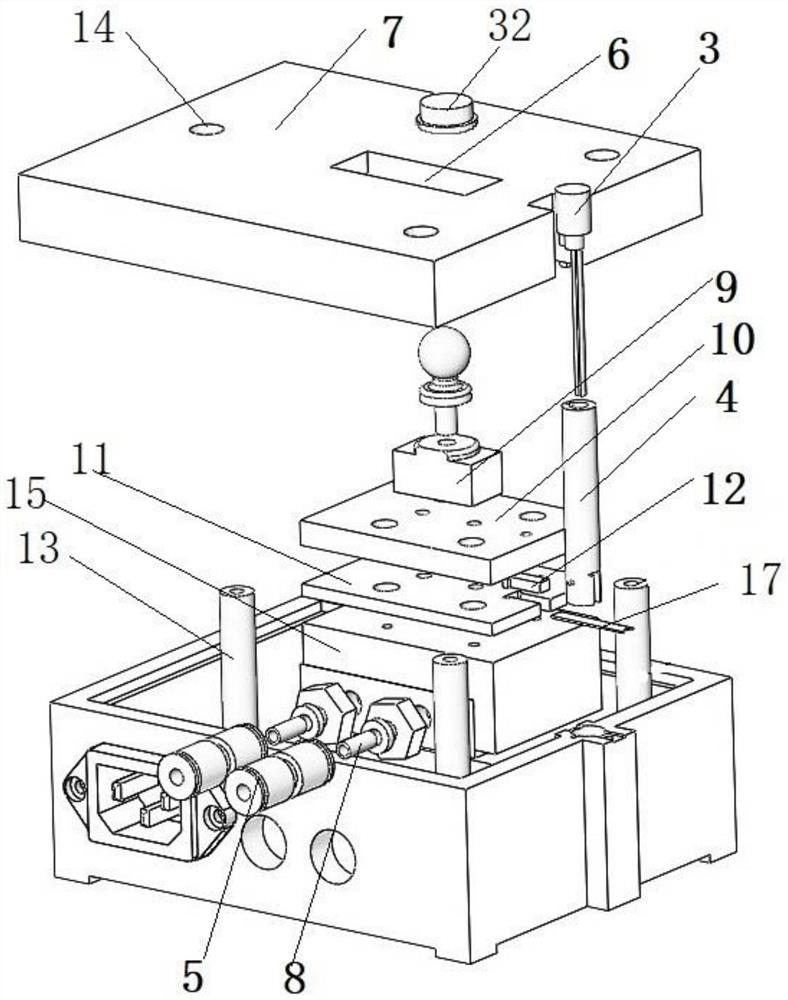

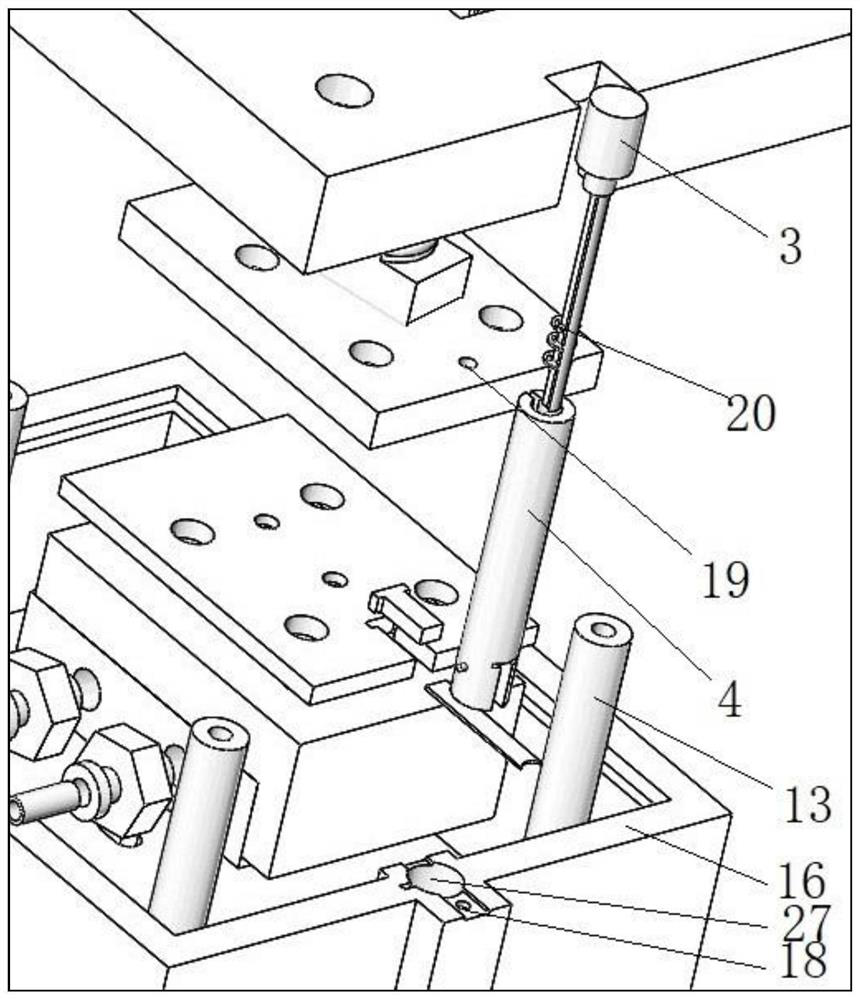

[0037] The automatic assembling device for the opening retaining ring of the vehicle-mounted relay of the present invention comprises a box body 16 and a cover plate 7; there are three columnar mounting seats 13 on the box body 16, and there are three mounting holes 14 at corresponding positions on the cover plate 7, the box body 16 and the cover plate 7 is covered by the socket 13 and the mounting hole 14; one end of the cover plate 7 is provided with a gap, which is used to place the material bin 4 inserted into the rack ring placement frame 3, the middle part is provided with a chute 6, and the lower part of the manual wrench 2 Connect the wrench seat 9, the upper part stretches out the cover plate 7 from the chute 6; one end of the box body 16 protrudes, and a circular feed bin installation hole 27 is provided vertically inward for inserting the feed bin 4, the feed bin A limiting concave hole 28 is processed on the edge of the mounting hole 27, a concave retaining ring lim...

Embodiment 2

[0046] The automatic assembling device for the opening retaining ring of the vehicle-mounted relay of the present invention comprises a box body 16 and a cover plate 7; there are three columnar mounting seats 13 on the box body 16, and there are three mounting holes 14 at corresponding positions on the cover plate 7, the box body 16 and the cover plate 7 is covered by the socket 13 and the mounting hole 14; one end of the cover plate 7 is provided with a gap, which is used to place the material bin 4 inserted into the rack ring placement frame 3, the middle part is provided with a chute 6, and the lower part of the manual wrench 2 Connect the wrench seat 9, the upper part stretches out the cover plate 7 from the chute 6; one end of the box body 16 protrudes, and a circular feed bin installation hole 27 is provided vertically inward for inserting the feed bin 4, the feed bin A limiting concave hole 28 is processed on the edge of the mounting hole 27, a concave retaining ring lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com