Device for machining circumferential inclined hole of nozzle nut of aero-engine

An aero-engine and nozzle technology, which is applied in the field of machining, can solve the problems of high quantity, poor efficiency and cost ratio, and large batch of parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

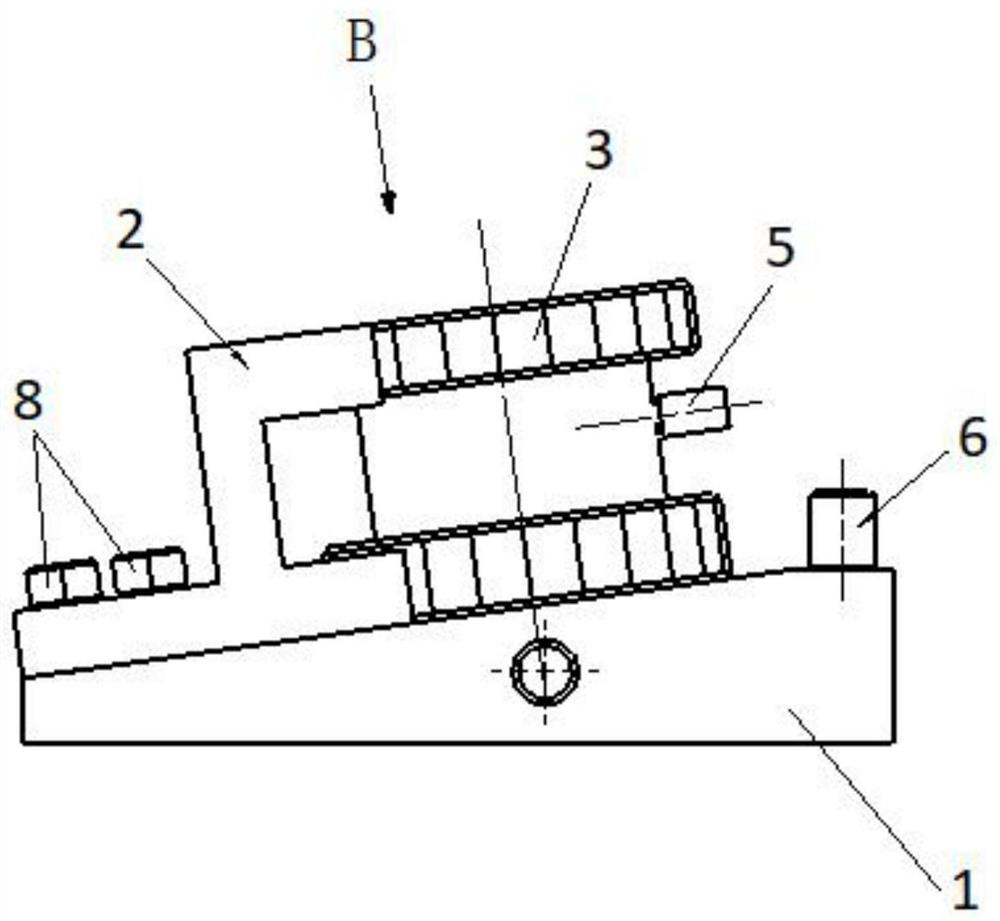

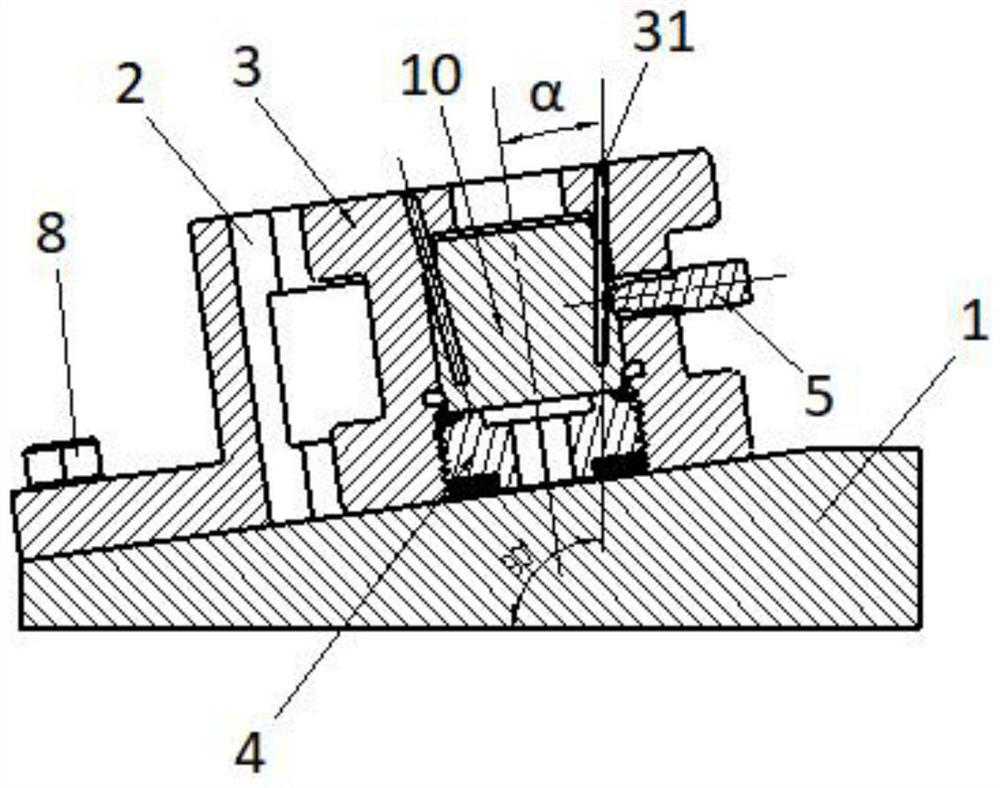

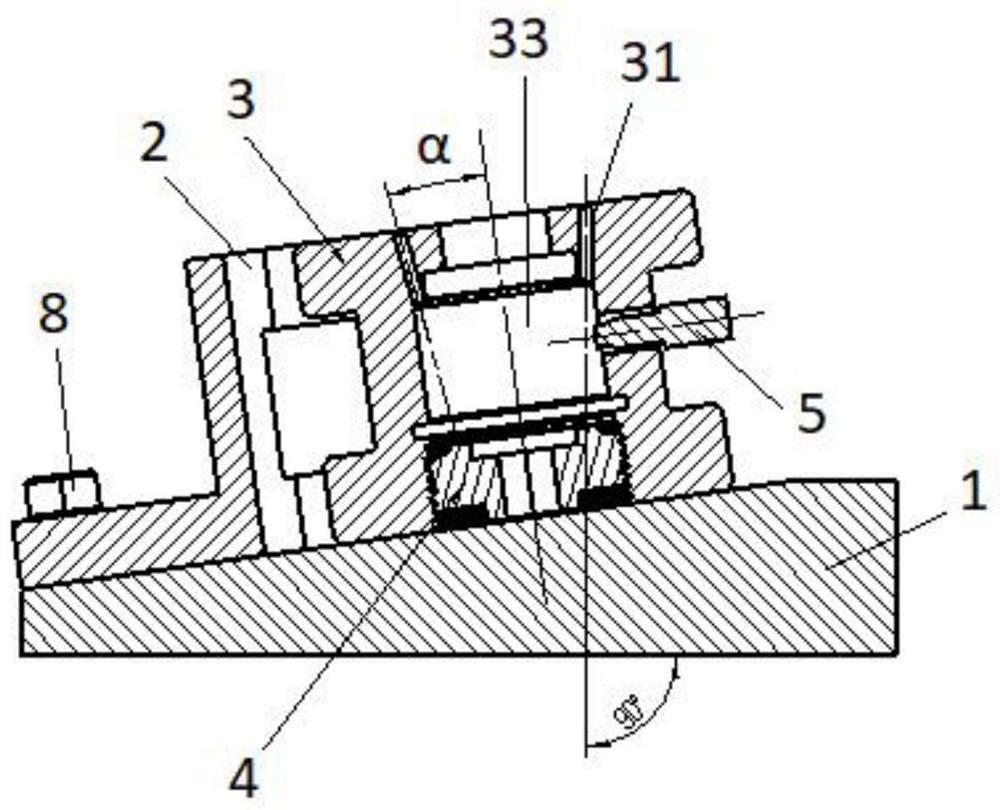

[0029] Such as Figure 1-8 As shown, a device for machining the circumferential oblique hole of the nozzle nut of an aero-engine includes a base 1, a V-shaped support 2, a drilling mold 3 and a compression nut 4. The upper surface of the base 1 is an inclined plane, and the V-shaped support 2. It is fixedly installed on the upper surface of the base 1; the V-shaped support 2 has a V-shaped groove, and the direction of the notch is upward along the slope of the base 1. The drilling template 3 is placed on the base 1, and one side of the drilling template 3 is embedded in the V-shaped In the V-shaped groove of the support 2; the drilling mold 3 is cylindrical, and an inner cavity 33 suitable for the part 10 to be processed is provided inside, and a circle is opened on the upper surface of the drilling mold 3 corresponding to the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com