Lightweight new energy bus aluminum alloy luggage compartment door and preparation process thereof

A new energy and lightweight technology, applied to doors, mechanical equipment, vehicle parts, etc., can solve problems such as luggage compartment penetration, large gaps, and passenger property damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Next, in connection with the accompanying drawings and specific embodiments, the present invention is further described, and it is to be noted that new embodiments may be formed in any combination of various embodiments or each of the techniques in the preceding embodiments. .

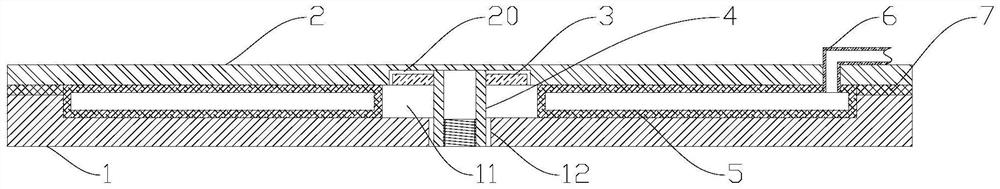

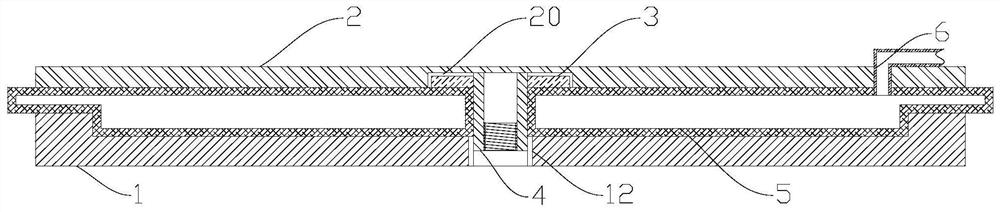

[0017] like Figure 1-2 As shown, lightweight new energy passenger car aluminum luggage door, including the door body 1, and the door body 1 is provided with a receiving groove 11 towards the side of the luggage compartment, and the inner diameter of the accommodating groove 11 is smaller than the door. The outer diameter of the body 1 is provided above the accommodating groove 11, and the outer diameter of the support plate 2 is larger than the inner diameter of the accommodating groove 11, and is less than or equal to the outer diameter of the door body 1. The bottom center of the support plate 2 is provided with a receiving hole 20, and the bottom center of the door body 1 is provided with an inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com